Locknut shim insert combination external member

A technology of locking nuts and washers, applied in nuts, threaded fasteners, screws, etc., can solve the problems of reducing the strength of nuts, unable to guarantee repeated use, deformation of bolt threads, etc., to improve friction, improve shaft The effect of increasing the force and improving the anti-loosening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

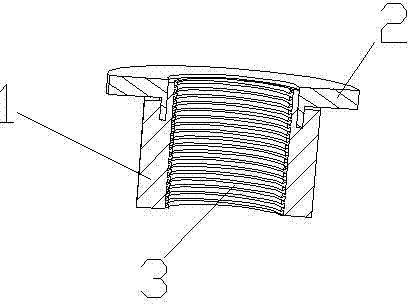

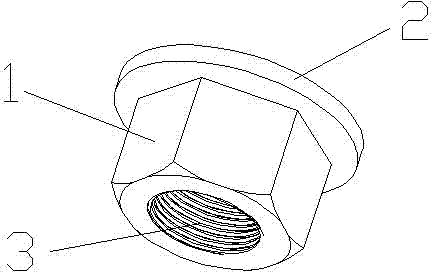

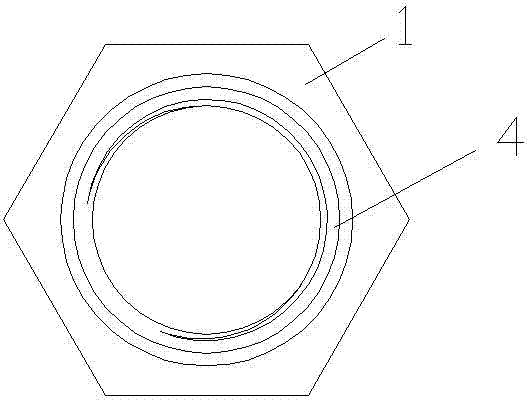

[0022] Such as Figures 1 to 6 As shown, this embodiment is composed of a nut body 1 , a washer body 2 , an axially extending body 5 , and a flange inlay body 6 . Wherein, the inside of the nut body 1 is provided with an internal thread 3 . An axial protruding body 5 is provided on the nut body 1 , and a nut groove 4 is provided beside the axial protruding body 5 . A flange inlay 6 is arranged on the washer body 2, and the flange inlay 6 is embedded in the nut groove 4. The height of the flange inlay 6 is greater than the depth of the nut groove 4, and the thickness of the flange inlay 6 is smaller than that of the nut. The width of groove 4. The height of the axially protruding body 5 is equal to the thickness of the washer body 2 , and the outer diameter of the axially protruding body 5 is equivalent to the inner diameter of the washer body 2 .

[0023] The axial extension body 5 is provided with two pairs of extension body narrow grooves 7 in the radial direction, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com