Sandstone water ratio measurement and control system and concrete production equipment comprising sandstone water ratio measurement and control system

A technology of measurement control and production equipment, applied in the direction of material inspection products, etc., can solve the problems of laborious, time-consuming, affecting the quality of concrete, etc., and achieve the effect of fast response, accurate measurement value, and sufficient moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

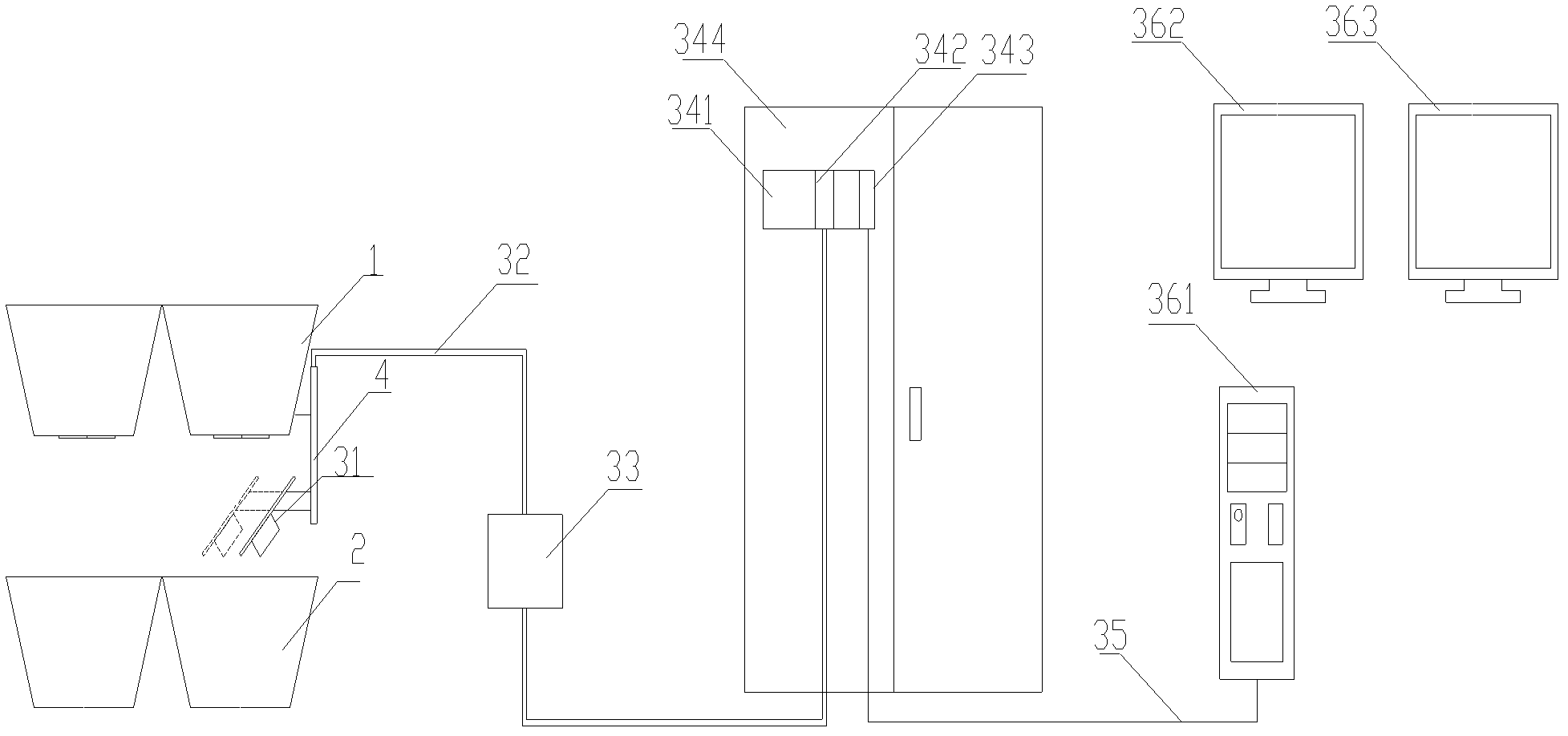

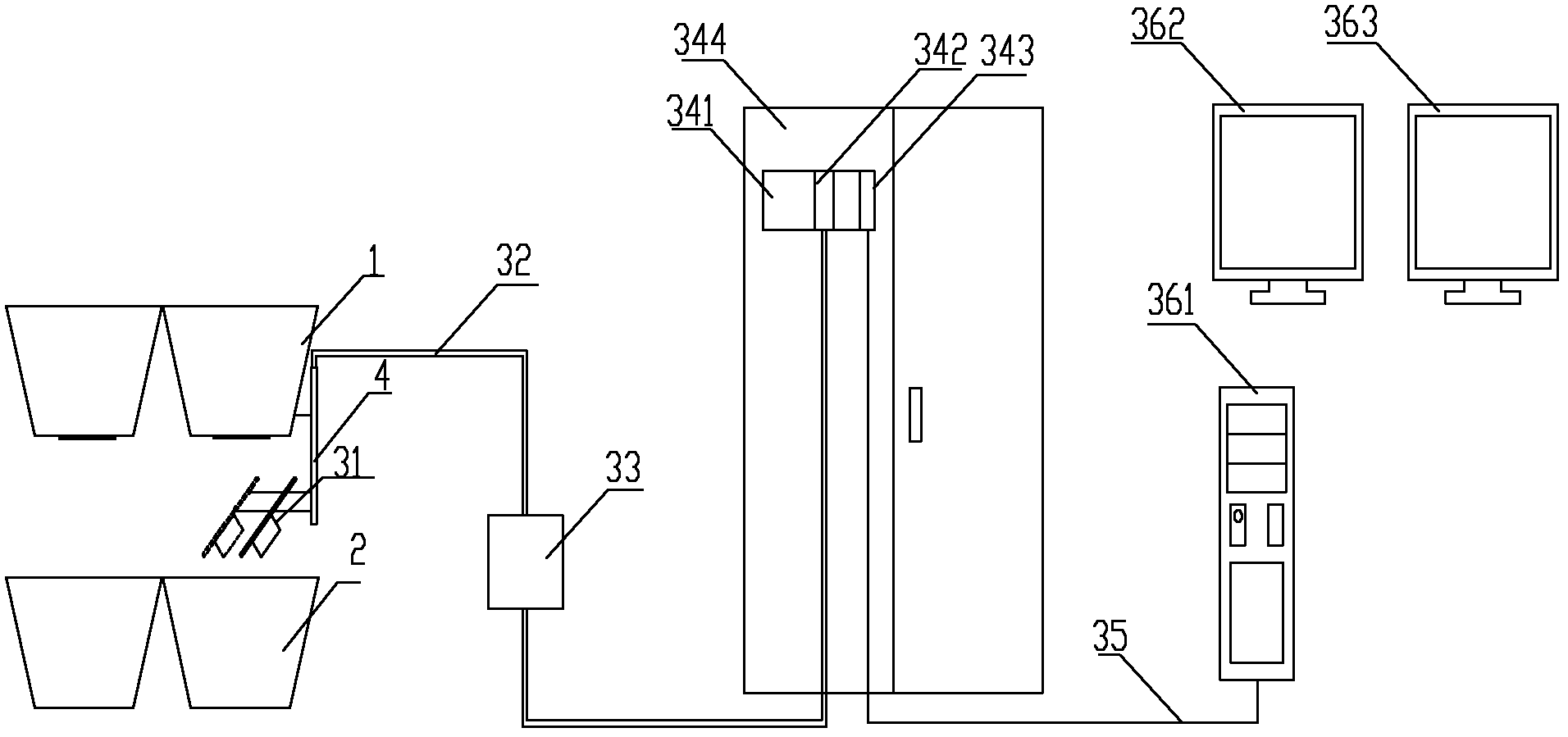

[0019] As an embodiment of the present invention, the concrete production equipment of the present invention includes a sand and gravel bin 1, a weighing bucket 2, a sensor mounting bracket 4 and a sand and gravel moisture content measurement and control system, such as figure 1 shown:

[0020] The sand water content measurement control system includes: sand water content sensor 31, connecting cable 32, junction box 33, I / O module 341, analog module 342, communication module 343, control cabinet 344, communication cable 35, industrial computer 361 , Display One 362 and Display Two 363.

[0021] The moisture content sensor 31 is fixedly installed on the sensor mounting bracket 4, located directly below the sand and gravel bin 1 and above the weighing bucket 2; the moisture content sensor 31 is connected with the connecting cable 32 and connected to the junction box 33; The I / O module 341 is connected; the I / O module 341, the analog module 342 and the communication module 343 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com