A sandstone moisture content measurement control system and concrete production equipment including the same

A production equipment, measurement and control technology, applied in the direction of material inspection products, etc., can solve the problems of affecting the quality of concrete, time-consuming, laborious, etc., and achieve the effects of fast response, accurate measurement values, and sufficient moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

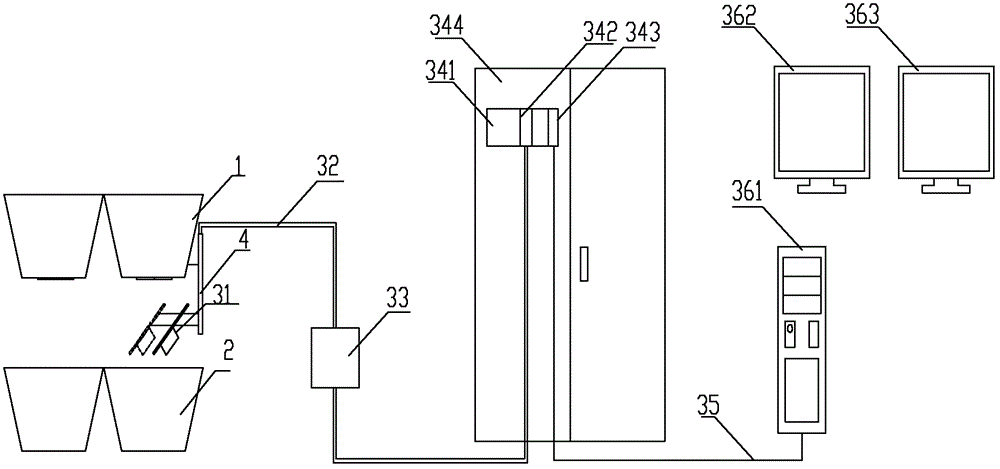

[0019] As an embodiment of the present invention, the concrete production equipment of the present invention includes a gravel bin 1, a weighing bucket 2, a sensor mounting bracket 4 and a gravel water content measurement and control system, such as figure 1 Shown:

[0020] The sand and gravel moisture content measurement control system includes: sand and gravel moisture content sensor 31, connecting cable 32, junction box 33, I / O module 341, analog quantity module 342, communication module 343, control cabinet 344, communication cable 35, industrial computer 361 , display one 362 and display two 363 .

[0021] The moisture content sensor 31 is fixedly installed on the sensor mounting bracket 4, located directly below the gravel bin 1 and above the weighing bucket 2; the moisture content sensor 31 is connected with the connecting cable 32 and inserted into the junction box 33; the junction box 33 and The I / O module 341 is connected; the I / O module 341, the analog module 342, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com