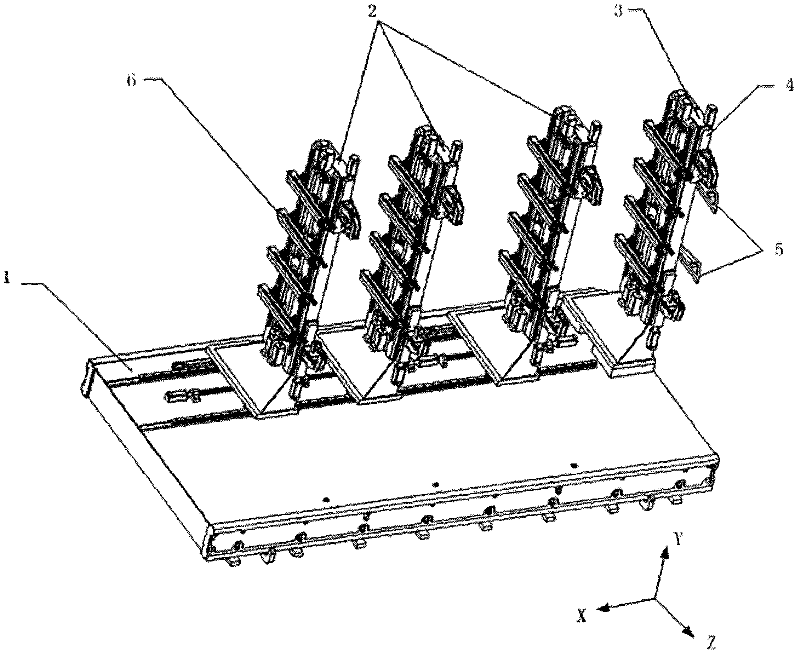

Method for assembling and positioning vertical column array type fuselage wall panel and device thereof

A technology for assembling positioning devices and fuselage wall panels, which is applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

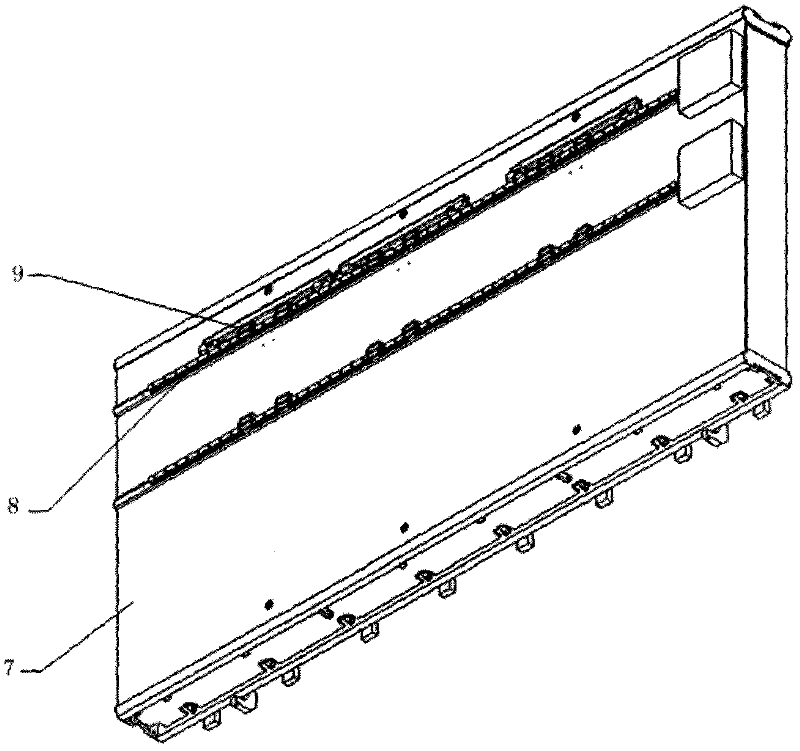

[0033] The aircraft fuselage panel (chord height 180mm) with curvature of length × width × thickness = 4500mm × 1500mm × 4mm is assembled and positioned, and the positioning accuracy is controlled within 0.1mm.

[0034] Method example:

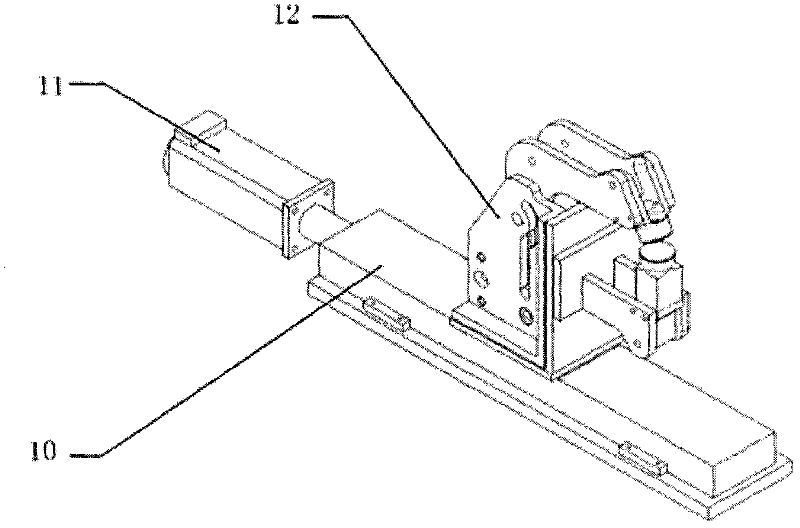

[0035] (1) Establish the three-dimensional model of the column array tooling and the fuselage panel, and set the assembly reference coordinate system in the three-dimensional model of the tooling. According to the structure, shape and size characteristics of the tooling and the 3D model of the fuselage panel, the relative position and attitude of the 3D model of the fuselage panel and the 3D model of the tooling are adjusted in the 3D CAD assembly environment, so that the panel is positioned in all positions of the tooling within the positioning range of the point to ensure that the fuselage panel can be successfully installed and positioned on the tooling;

[0036] (2) The positioning method of N-2-1 is adopted (the inner surface of the wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com