Quickly-installed training panel and electrician training cabinet using same

A panel and fast technology, which is applied to educational appliances, casings/cabinets/drawer parts, instruments, etc., can solve problems such as high labor intensity, achieve the effect of reducing labor intensity and fast replacement and installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

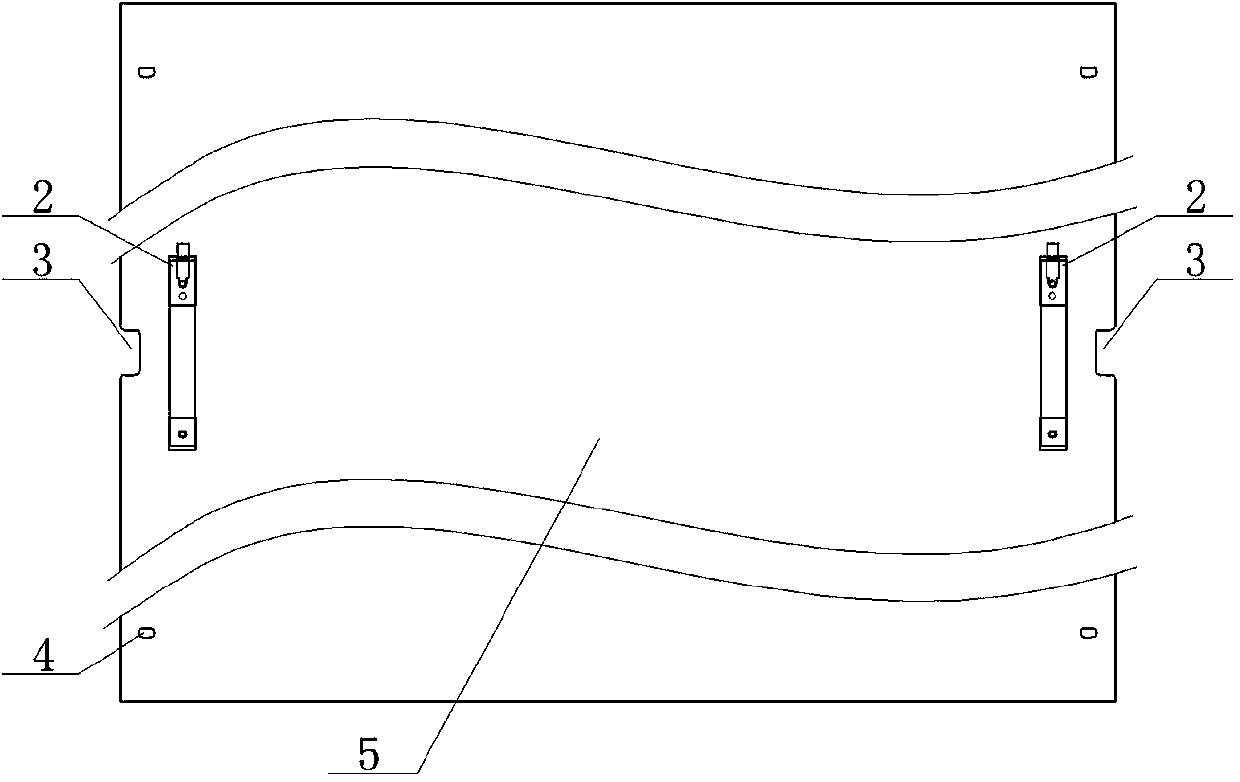

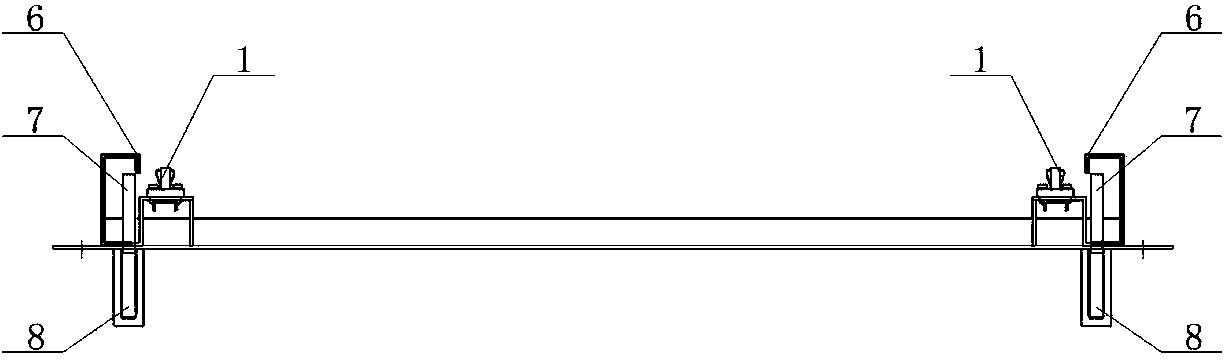

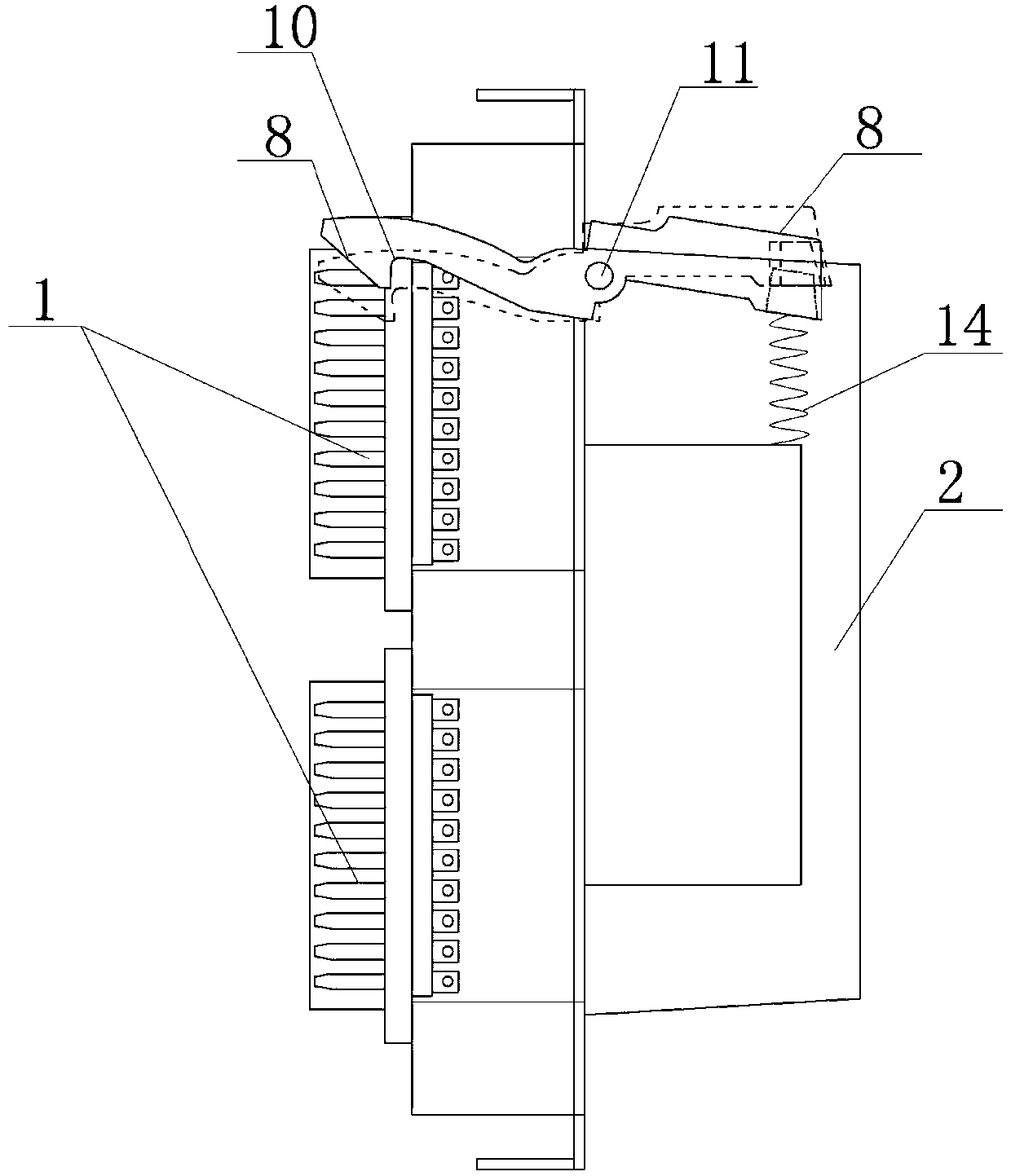

[0027] Examples of quick installation training panels for this application Figure 1~8 Shown: Quickly install the training panel 5, including the outer panel surface for the installation of the corresponding operating unit 17, the inner panel surface of the training panel 5 is fixedly connected to the corresponding operating unit 17 and is used for connecting The corresponding electrical connector socket 13 is mated with the electrically connected electrical connector plug 1, and the insertion direction of the electrical connector plug 1 and the electrical connector socket 13 is extended along the inner and outer directions of the training panel 5, so The training panel 5 is provided with guide grooves (or guide holes) for guiding and sliding assembly on the corresponding cabinet body 15 along the inner and outer directions, and the training panel 5 is also provided with guide slots for corresponding cabinet body 15. The locking member cooperates to lock the training panel 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com