Spreading machine for battery

A technology of glue coating machine and battery, which is applied in the direction of coating, device for coating liquid on the surface, etc., can solve the problems of inability to meet the requirements of mass production, low production efficiency, and alkali leakage and climbing of batteries, so as to reduce alkali leakage. The effect of alkali climbing phenomenon, uniform and stable coating layer, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

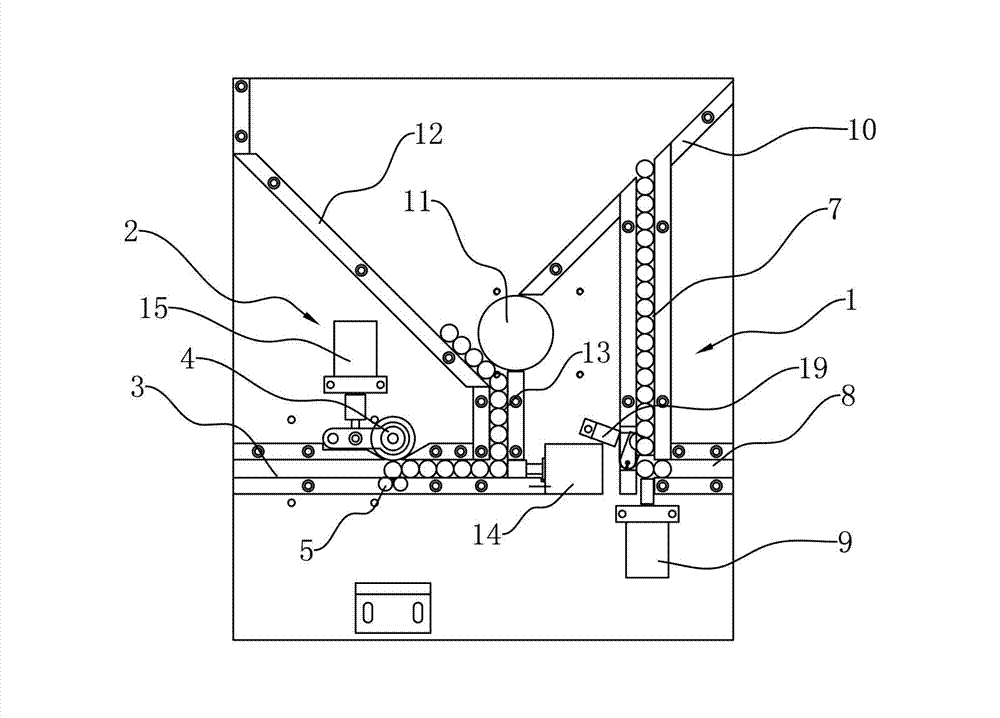

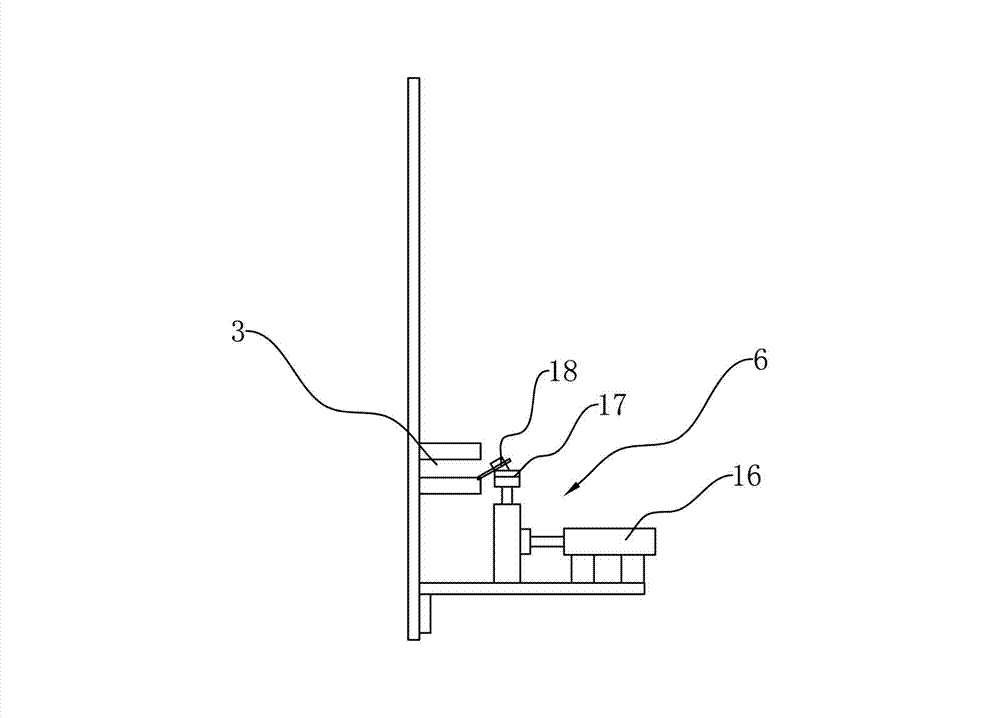

[0012] refer to figure 1 , figure 2 , a battery gluing machine of the present invention, comprising a feeding mechanism 1, a sorting mechanism 2 is arranged in the output direction of the feeding mechanism 1, and a horizontal conveying trough 3 is arranged on the said sorting mechanism 2, and a pressure roller is installed above the transverse conveying groove 3 4. The support wheel 5 corresponding to the pressure roller 4 is installed under the horizontal conveying tank 3, and the battery gluing area is formed between the pressure roller 4 and the support wheel 5, and the side of the battery gluing area is correspondingly installed with a glue spraying mechanism 6. Due to the adoption of the above-mentioned structure, this battery gluing machine changes the original manual operation of gluing with a needle to a pneumatic glue spraying mechanism for uniform gluing, which is reliable and fast in quality, greatly reduces personnel operations, and makes the gluing layer uniform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com