Dynamic slight press fan-shaped section deformation on-line measuring and compensating method

A compensation method and sector segment technology, which is applied in the field of continuous casting control in the metallurgical industry, can solve problems such as sensor value drift, inability to produce high-quality variety steel, and poor quality stability of casting slabs, so as to ensure shrinkage taper and quality of casting slabs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

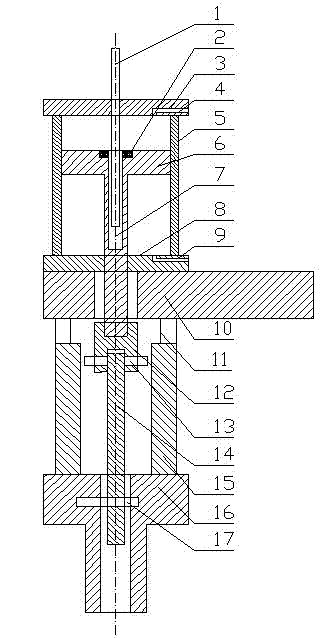

[0031] The invention is divided into two parts, the online measurement of the deformation of the sector and the online compensation of the deformation of the sector.

[0032] 1. On-line measurement of sector deformation

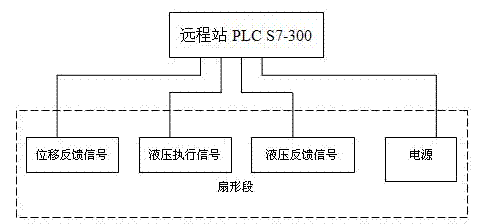

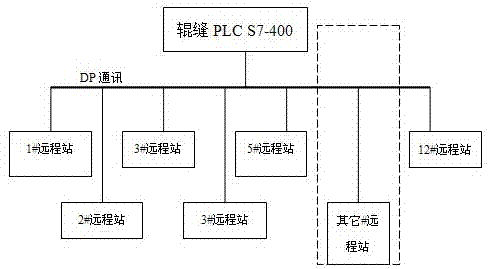

[0033] At the end of steel pouring, the sector is forcibly closed through the PLC S7-400 to the 6 remote stations PLC S7-300, and the sector is raised to state 2 in Table 1 after holding for 2 minutes. At this time, the sector The upper frame of the section is not supported by the supporting force of the block. Then adjust the sector system pressure to gradually increase from 0MPa to 19MPa. PLC S7-400 receives the value change of the displacement sensor sent by PLC S7-300, and PLC S7-400 regresses the system pressure and the value of the displacement sensor to form a correction equation. See Table 2~Table 7 for the force and deformation data of 5#~10# sectors.

[0034]

[0035]

[0036]

[0037] 2. On-line compensation of sector deformation

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com