Built-in dual-wheel and tire-bursting safer

A built-in safety device technology, applied to tire parts, transportation and packaging, vehicle parts, etc., can solve problems such as complex installation, achieve practical and reliable, convenient manufacturing, and prevent rollover effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

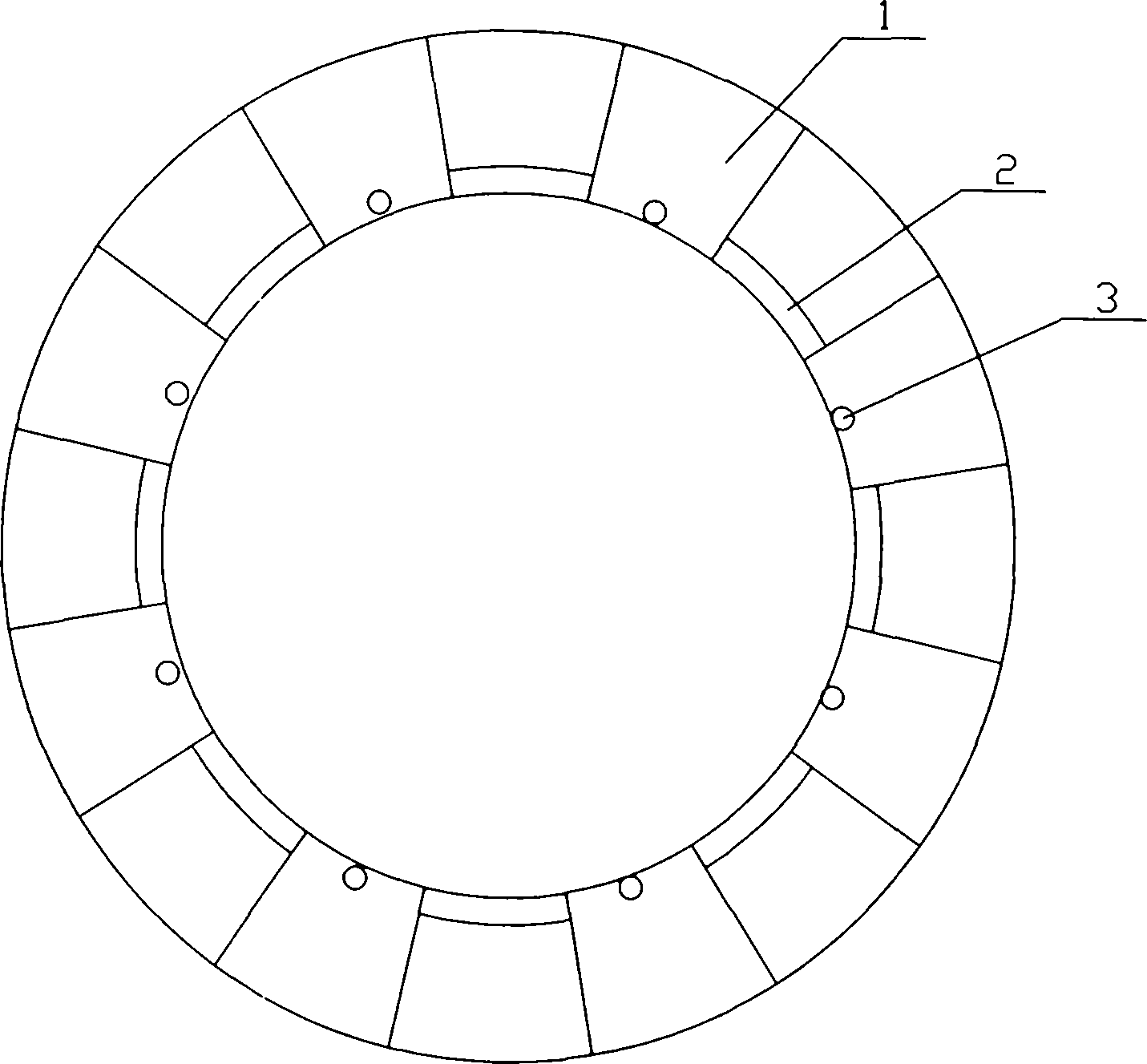

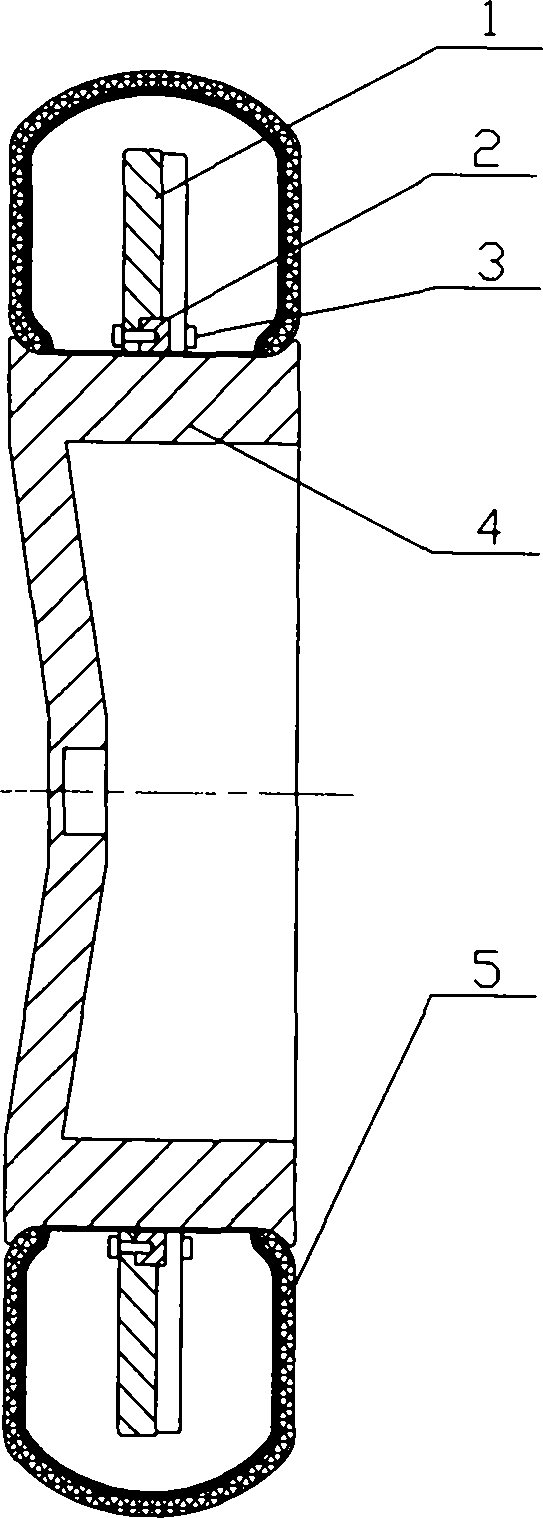

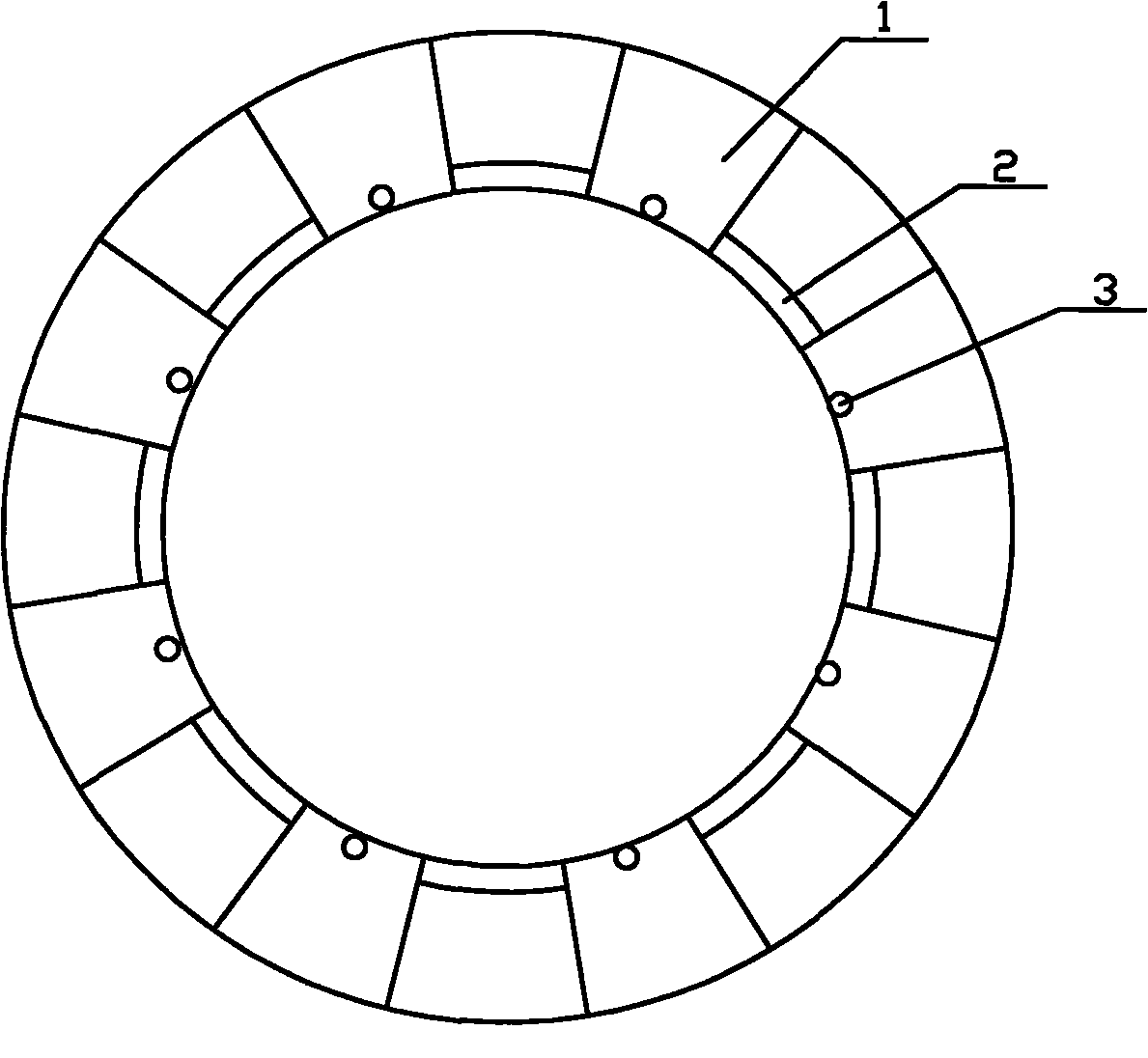

[0011] Built-in double-wheel blowout safety device, which includes sixteen fan-shaped plates 1 and connecting rings 2, the fan-shaped plates 1 are flat, and the sixteen fan-shaped plates 1 are divided into two groups, each group is eight, and they are evenly distributed in a ring On the two radial sections of the hub 4, there is a gap between each sector plate 1, and the positions of two sets of sector plates 1 are interlaced. Sector plate 1 top place cylindrical surface diameter is smaller 2-10 centimetres than tire 5 outer diameters than the wheel diameter that it is installed. The connecting ring 2 is arranged around the hub 4 and fixed to the side of the hub 4 of the wheel. Two sets of fan-shaped plates 1 are respectively fixed on both sides of the connecting ring 2 by screws 3 . The number of sector plates 1 can be 6-16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com