Suedette blackout face fabric

A technology of imitation suede and fabrics, applied in fabrics, textiles, textiles and papermaking, etc., can solve problems such as human injury and environmental pollution, achieve the effects of improving anti-wrinkle performance, increasing warp and weft density, reducing environmental pollution and resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

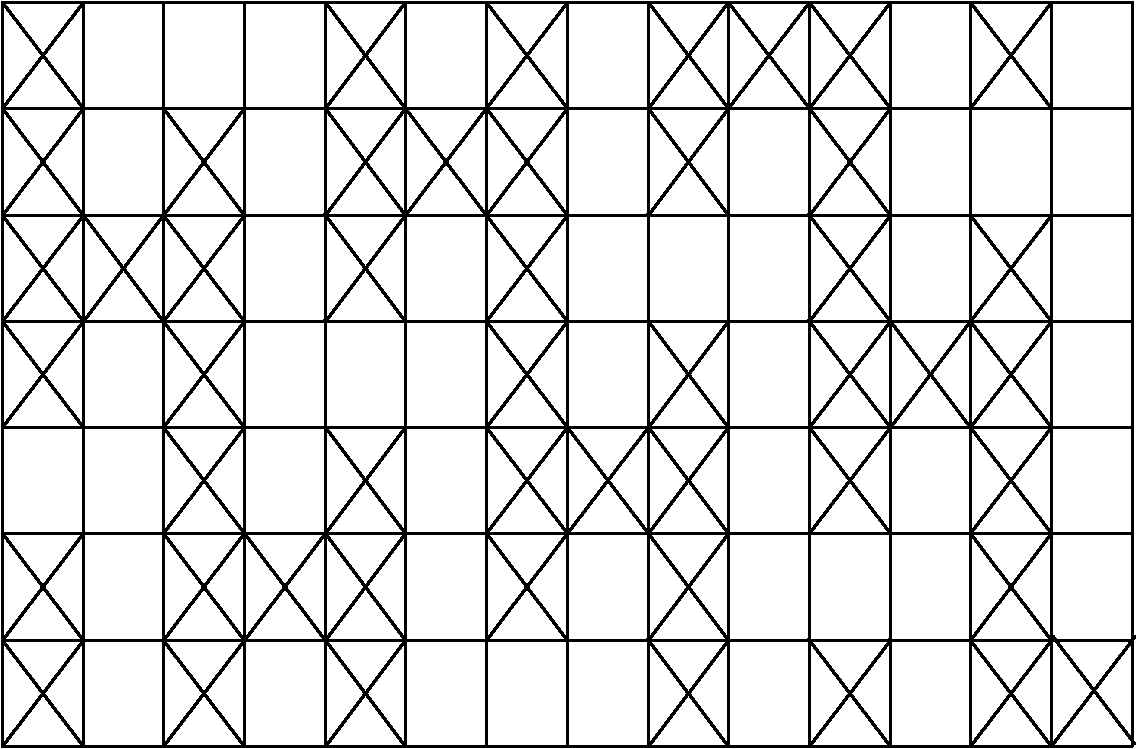

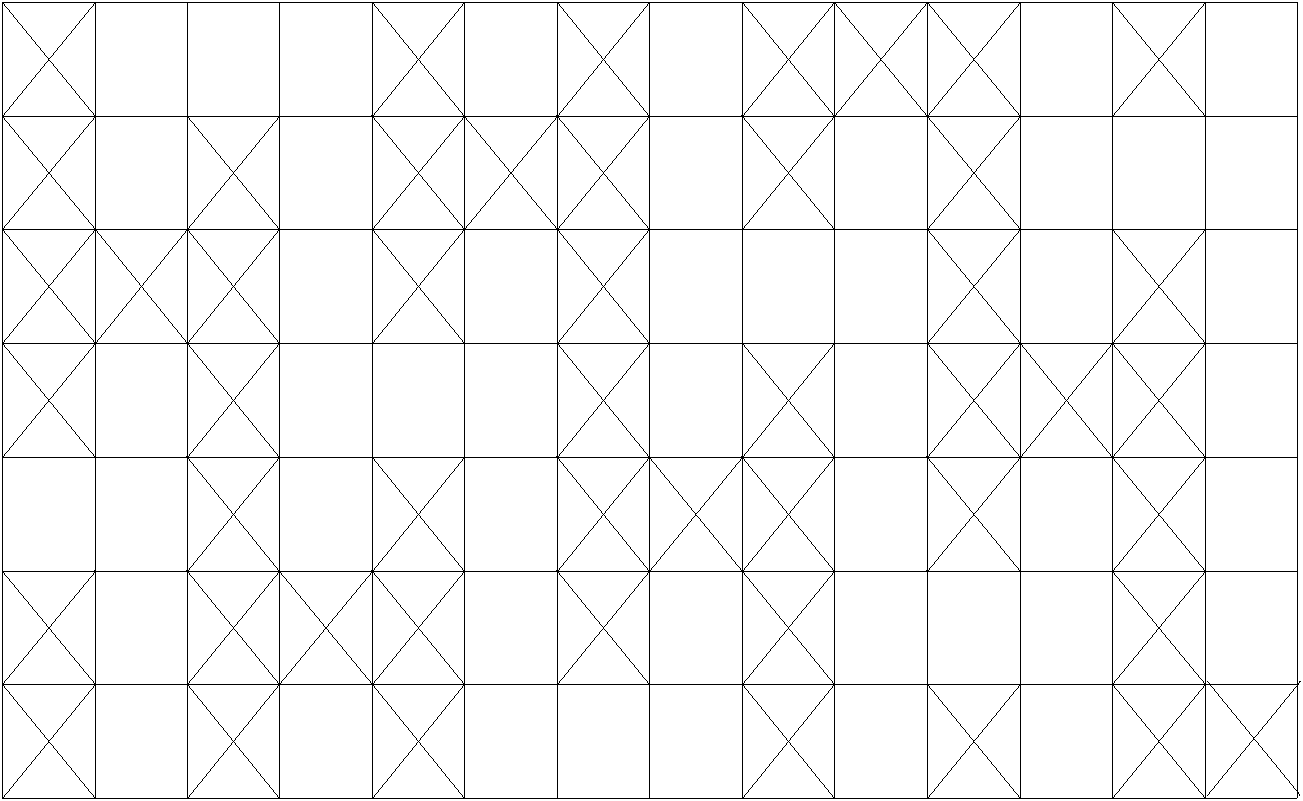

Image

Examples

Embodiment 1

[0015] Example 1: One group of warp yarns is 50D / 48F fully drawn yarn FDY and 50D / 48F pre-oriented yarn POY composite different shrinkage yarn, the other group of warp yarns is 75D / 72F matte polyester low elastic yarn, and the weft yarn is 300D / 96F Polyester black silk; the total number of warps is 39,040; the warp density is 82 threads, and the weft thread density is 65 threads.

Embodiment 2

[0016] Example 2: One group of warp yarns is 65D / 120F fully drawn yarn FDY and 65D / 120F pre-oriented yarn POY compound different shrinkage yarn, the other group of warp yarns is 79D / 85F matte polyester low elastic yarn, and the weft yarn is 160D / 114F Polyester black silk; the total number of warps is 38,530; the warp density is 72 threads, and the weft density is 90 threads.

Embodiment 3

[0017] Example 3: One group of warp yarns is 78D / 256F fully drawn yarn FDY and 78D / 256F pre-oriented yarn POY compound different shrinkage yarn, the other group of warp yarns is 55D / 150F matte polyester low elastic yarn, and the weft yarn is 320D / 244F Polyester black silk; the total number of warps is 42,100; the warp density is 102 threads, and the weft thread density is 85 threads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com