Transfer pump of high viscosity fluid

A fluid transmission, high viscosity technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of difficult processing of tooth profile curves, shorten the service life of pumps, affect the stability of transmission, etc., and achieve low cost , prolong service life, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited to the following description.

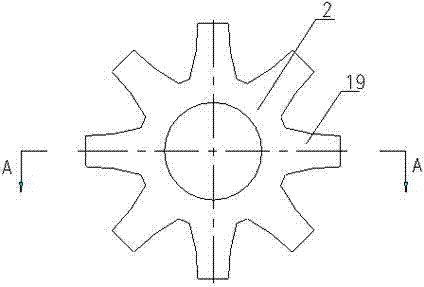

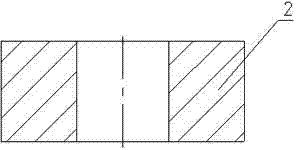

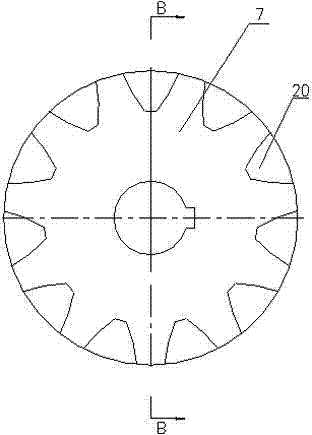

[0021] like Figure 7 As shown, a high-viscosity fluid transmission pump includes an end cover 1, an internal gear 2, a fixed shaft 4, a pump body 5, an external gear 7, a right end cover 8, a bracket 12 and a drive shaft 15, and the internal gear 2 and The internal meshing gear pair composed of external gear 7 is installed in the pump body 5, and the end cover 1 and the right end cover 8 are respectively installed on the left and right sides of the pump body 5. The crescent plate 21 on the end cover 1 divides the inner space of the pump into a low-pressure area and a high-pressure area. zone, respectively for the fluid in and out. The gland 6 is installed above the pump body 5, the internal gear 2 is connected and fixed with the end cover 1 through the fixed shaft 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com