Hydraulic clutch and method for determining an adaptive clutch fill volume or return spring pressure

A technology of hydraulic clutch and filling volume, which is applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc. It can solve problems such as expensive components and complex technologies, and achieve the effects of cost reduction and improvement, quality reduction and saving, and applicability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

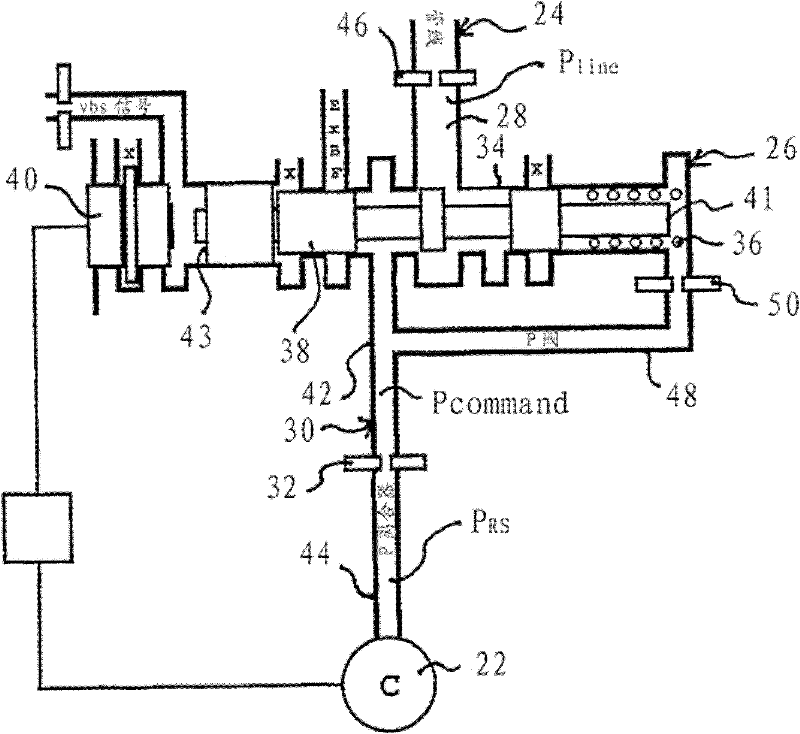

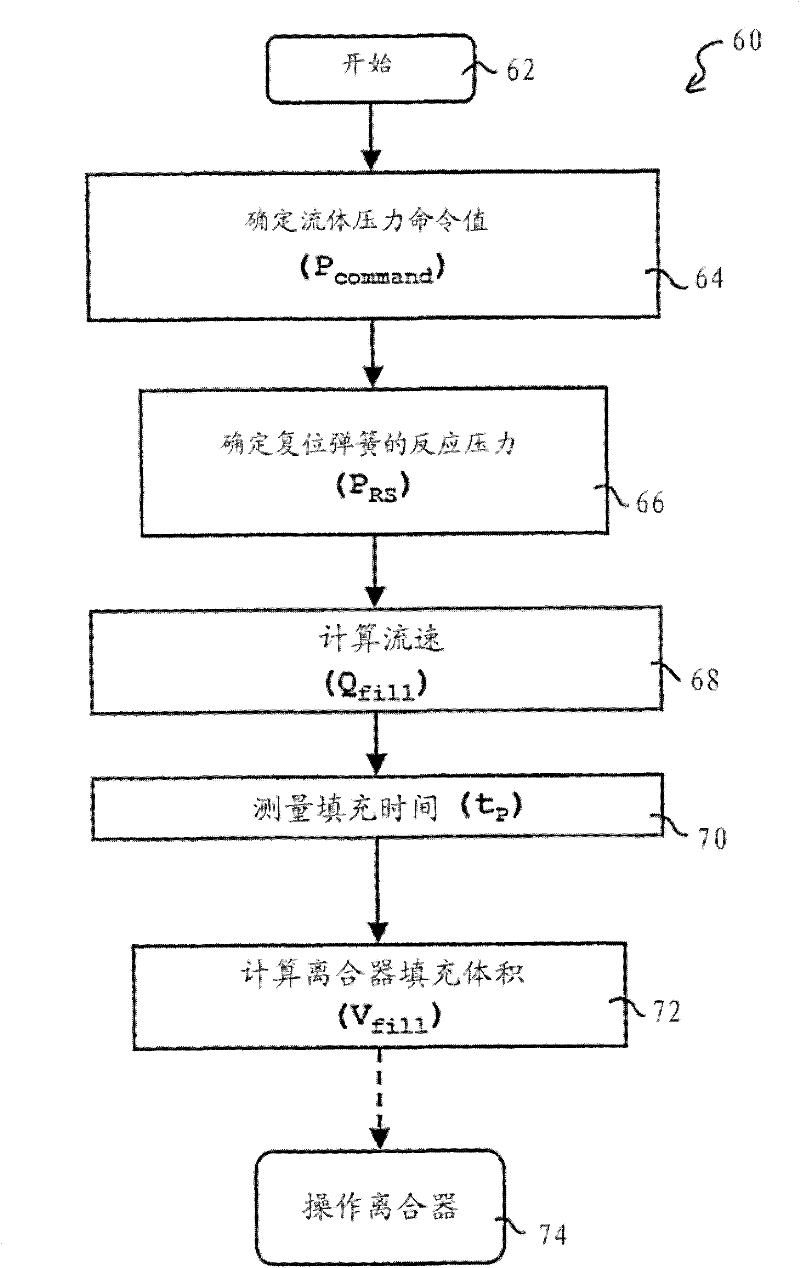

[0193] In the following description, the embodiments are described in detail. It will be apparent to those skilled in the art that the embodiment may be practiced without these details. Figure 1-15 Components with the same reference number are included. The description of these components is hereby incorporated by reference.

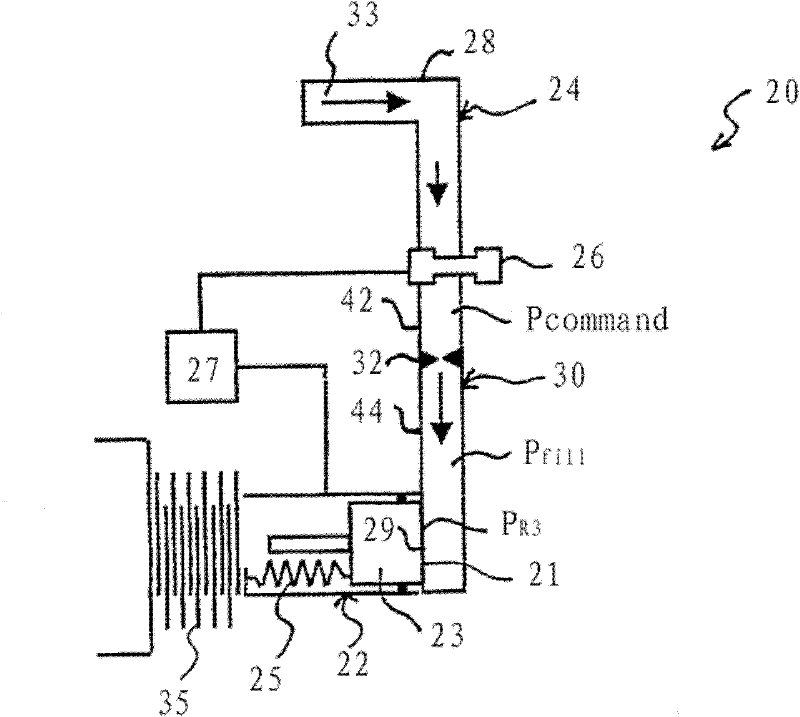

[0194] figure 1 A hydraulic clutch assembly 20 is shown including a hydraulic clutch 22 , a fill line 24 and a clutch fill regulator valve 26 . The hydraulic clutch 22 is connected to a first end 21 of a fill conduit 24 filled with hydraulic oil 33 . A regulator valve 26 divides the fill conduit 24 into an upstream tube 28 and a downstream tube 30 . In other words, the upstream pipe 28 and the downstream pipe 30 are joined together via the regulator valve 26 . Downstream conduit 28 also connects regulator valve 26 to hydraulic clutch 22 .

[0195] Hydraulic clutch 22 includes two arrays of piston 23 , return spring 25 and rotating friction element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com