Detection for corrosion of stayed cable and evaluation method thereof

A technology for corroded stay cables and detection devices, applied in the direction of testing wear resistance, etc., can solve the problems of not considering the influence of cables, not considering the degree of corrosion of steel wires, not considering the influence of internal force distribution of the structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0116] This method is applicable to the detection and evaluation of the most common semi-parallel stay cables in China, and consists of the following steps:

[0117] 1 Install cable corrosion early warning detection device;

[0118] 2 Carry out relevant inspections and tests on the cables;

[0119] 3 Evaluate the bearing capacity of the cable;

[0120] 4 Set the detection interval of the cable.

[0121] 1. Setting of cable corrosion early warning detection device

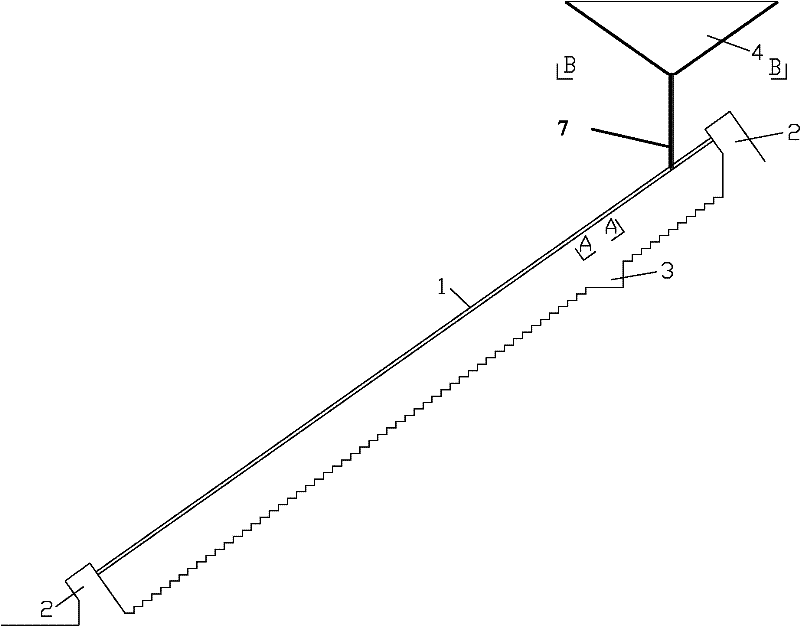

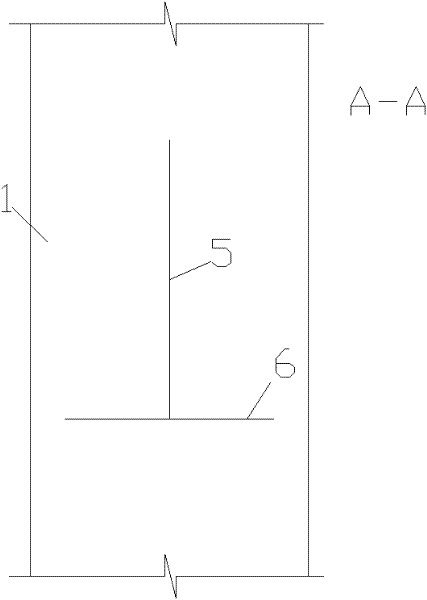

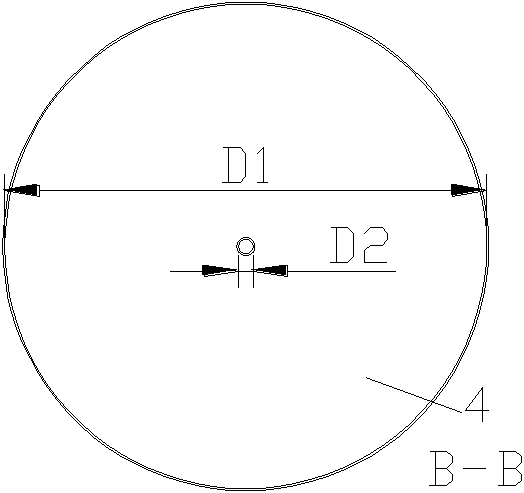

[0122] Such as figure 1 As shown, the cable corrosion early warning detection device includes the following parts: test cable 1, test cable anchor device 2, test cable detection platform 3, and test cable rain collection device 4.

[0123] The test cable shall meet the following requirements:

[0124] 1) In order to ensure that the speed of rainwater flowing up and down the tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com