Tripod automatic spot welding method and device

An automatic spot welding and tripod technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as low efficiency and poor product consistency, and achieve the effect of improving work efficiency and ensuring welding stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Obviously, many modifications and changes made by those skilled in the art based on the gist of the present invention belong to the protection scope of the present invention.

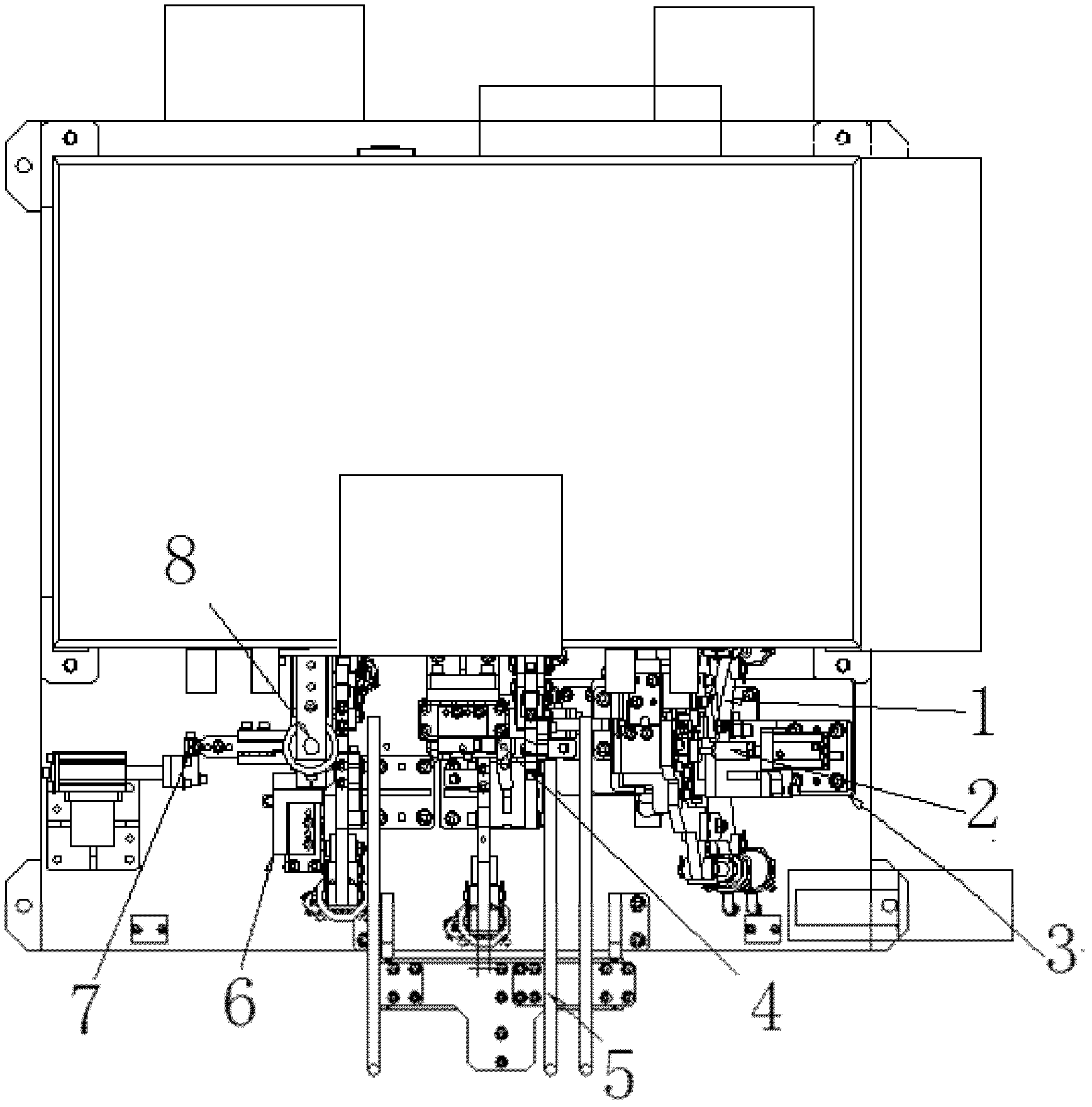

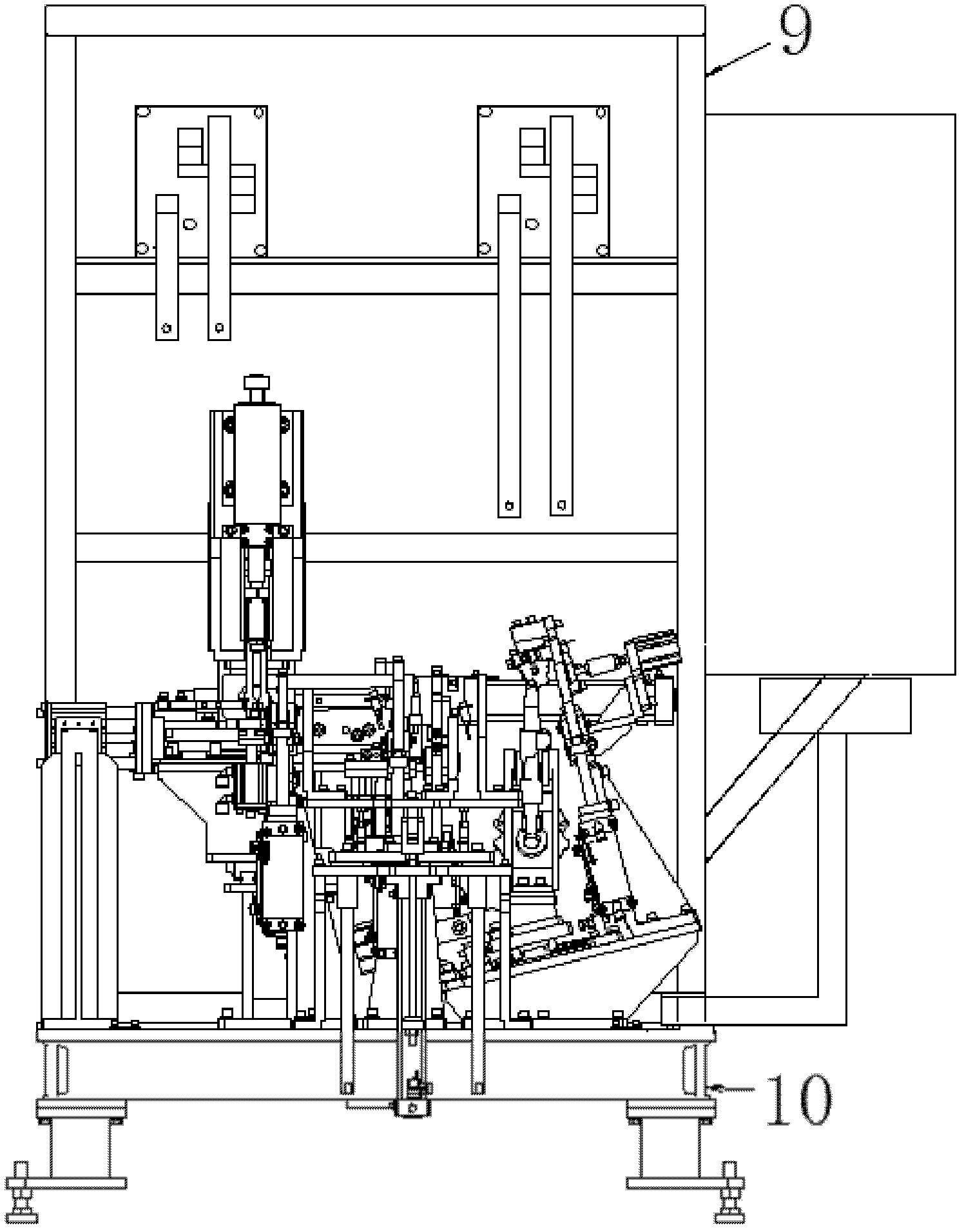

[0029] The present invention is mainly composed of four mechanical parts, namely: clamping and positioning mechanism, unloading and ejecting mechanism, spot welding mechanism, and working platform;

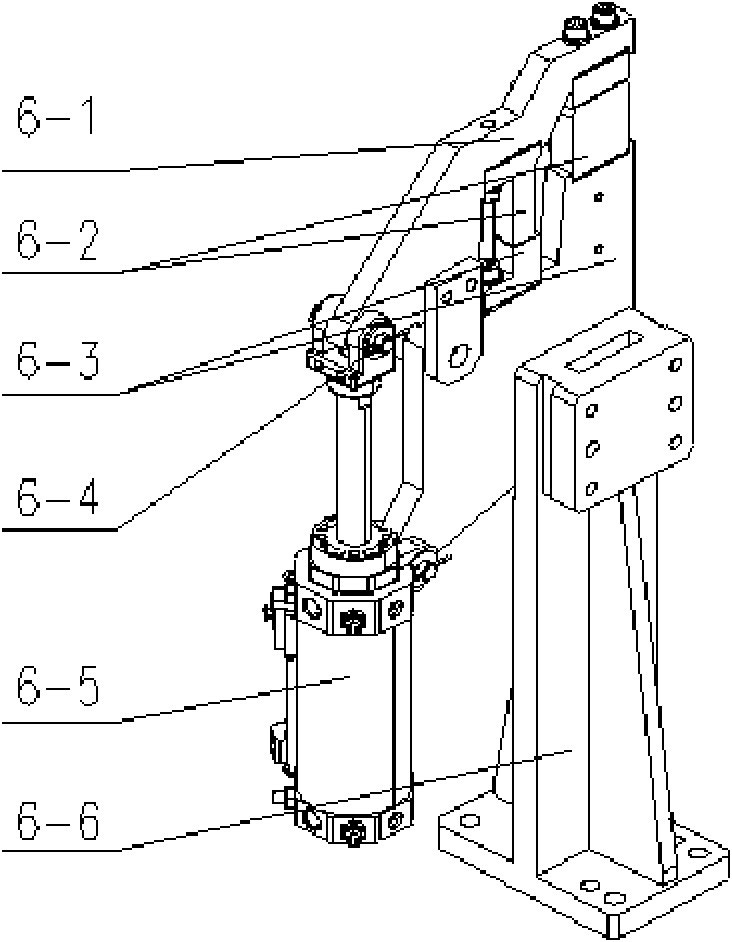

[0030] Among them: the clamping and positioning mechanism includes five sub-organizations, the first clamping and positioning mechanism 1, the second clamping and positioning mechanism 4, the third clamping and positioning mechanism 6, the fourth clamping and positioning mechanism 7, and the fifth clamping and positioning mechanism 2. Act on the three parts of the chute, triangular plate and small bracket respectively to ensure that the position of the parts does not deviate.

[0031] The spot welding mechanism includes two sub-organizations, the first spot welding mechanism 8 completes the spot weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com