Method for machining car differential shell

A processing method and differential gear technology, which is applied in the processing field of car differential housings, can solve the problems of inability to realize general processing, large investment in equipment costs, and long product development cycle, so as to shorten product development time and reduce processing costs. The effect of less cost and equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

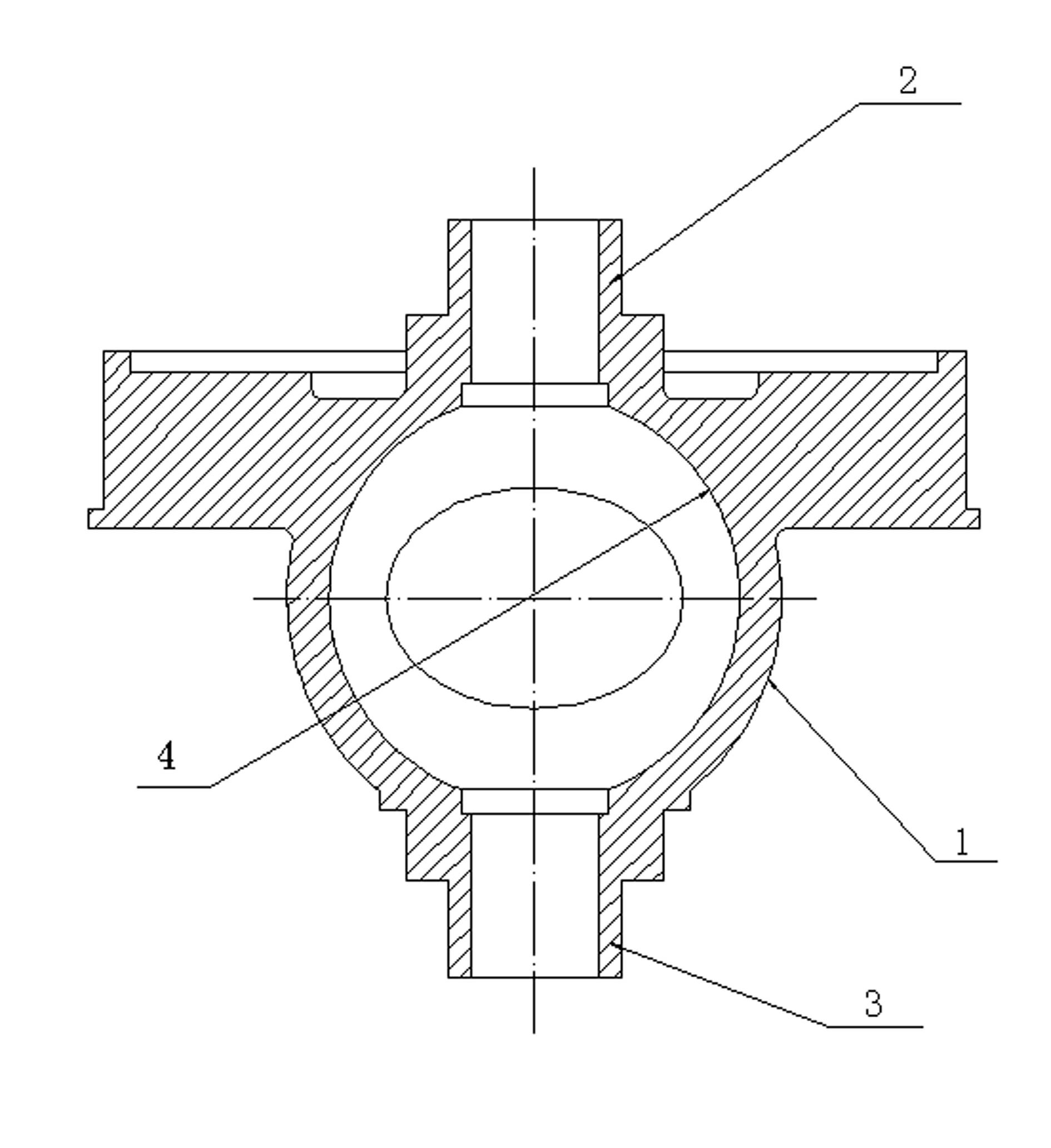

[0014] Such as figure 1 As shown, the present invention is further described as follows:

[0015] The processing method of car differential housing, the specific steps are:

[0016] (1) On a CNC lathe, rough turn the end face, outer circle, and axial inner hole of one end 2 of the car differential housing, and chamfer;

[0017] (2) On the CNC lathe, rough turn the end face, outer circle, axial inner hole, annular groove of the other end 3 of the car differential housing, and chamfer;

[0018] (3) On a CNC lathe, finish turning the outer circle described in step (1) and the outer circle and annular groove described in step (2);

[0019] (4) On the machining center, finish machining the axial bore described in step (1) and step (2);

[0020] (5) On the machining center, finish machining the inner cavity spherical surface 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com