Profile plate for train carriage

A profile and carriage technology, applied in the direction of railway car body, railway car body parts, transportation and packaging, etc., to achieve the effect of convenient manufacturing, reducing manufacturing cost and improving manufacturing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

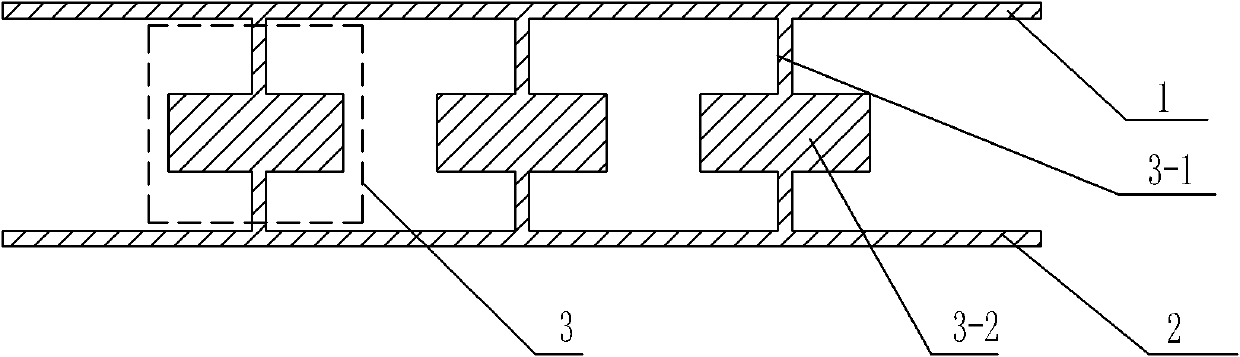

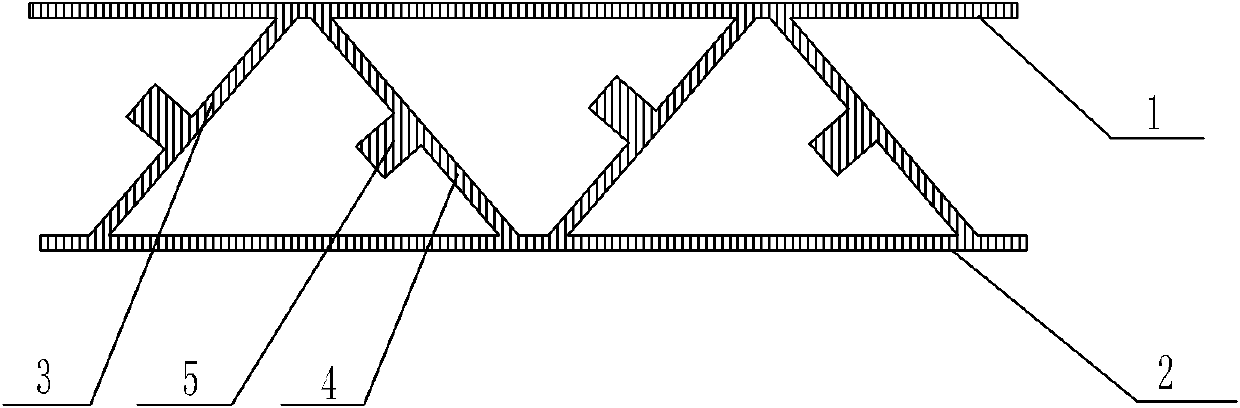

[0010] Specific implementation mode one: combine figure 1 Describe this embodiment, the profile plate of this embodiment includes a horizontal upper plate 1 and a horizontal lower plate 2, and the profile plate also includes a plurality of cross-shaped components 3, and each cross-shaped component 3 is composed of a vertical plate 3-1 and a horizontal set The noise-reducing and vibration-reducing plate 3-2 is composed of the vertical plate 3-1 and the horizontally arranged noise-reducing and vibration-reducing plate 3-2. Between the horizontal upper plate 1 and the horizontal lower plate 2, the horizontal upper plate 1, the horizontal lower plate 2 and a plurality of cross-shaped components 3 are integrated.

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the thickness of each rectangular vibration and noise reduction plate 4 in this embodiment is 0.02m. This structure can improve the effect of vibration and noise reduction under the premise of ensuring the same quality. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

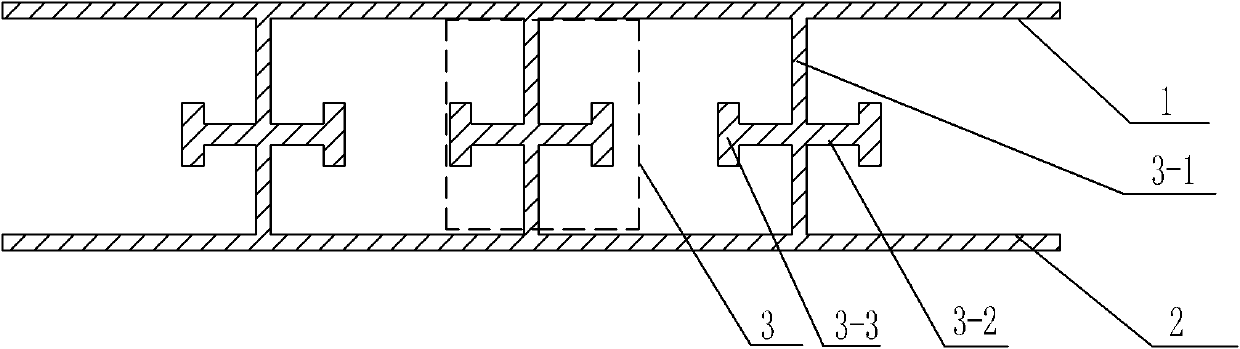

[0012] Specific implementation mode three: combination figure 2 To illustrate this embodiment, the profile plate in this embodiment includes a horizontal upper plate 1 and a horizontal lower plate 2, and the profile plate also includes a plurality of cross-shaped assemblies 3, each cross-shaped assembly 3 is composed of a vertical plate 3-1 and The horizontal noise reduction and vibration reduction plate 3-2 is composed of the vertical plate 3-1 and the horizontal noise reduction and vibration reduction plate 3-2, and the two ends of the horizontal noise and vibration reduction plate 3-2 are respectively provided Boss 3-3, a plurality of cross-shaped components 3 are arranged at equal intervals along the length direction of the upper plate 1 between the horizontal upper plate 1 and the horizontal lower plate 2, the horizontal upper plate 1, the horizontal lower plate 2 and the plurality of cross-shaped components 3 made into one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com