Hydrophobic modification method for Y-shaped molecular sieve

A technology of hydrophobic modification and molecular sieve, which is applied in the directions of eighthedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of poor effect and complicated hydrophobic modification method of Y-type molecular sieve, and achieves easy operation, The effect of overcoming uneven product properties and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Evenly spread and disperse the NaY molecular sieve baked at 400-500°C for 2 hours in the quartz wool, then put the quartz wool into the reaction furnace vertically,

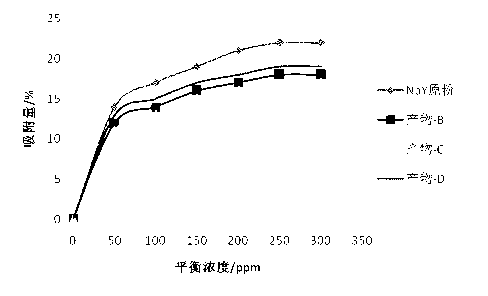

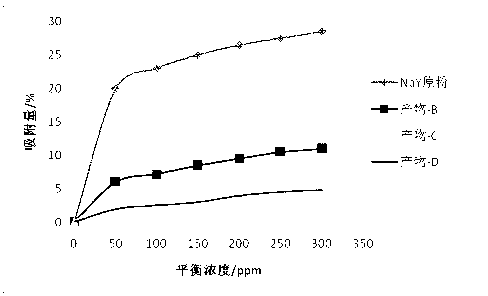

[0045] SiCl at room temperature by bubbling 4 Saturated N 2 into the reaction furnace, the initial temperature of the reaction furnace is set at 250°C, the heating rate is 6k / min, the final reaction temperature is 500°C, and the reaction time is 60 minutes. After the reaction, continue to pass N 2 30 minutes, then the molecular sieves were cooled to room temperature (the product obtained thus far is called Product B). Remove the molecular sieve and wash it with deionized water until the filtrate is free of Cl - , and then put the molecular sieve into the hydrochloric acid solution with a concentration of 1mol / L, and reflux at 100°C for 1 hour under stirring conditions (the product obtained so far is called product C). Dry the obtained product, continue to wrap it with quartz wool and put it vertically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com