Patents

Literature

37results about How to "Not easy to coalesce" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyacrylamide microsphere deep profile control agent and preparation method and application thereof

ActiveCN108315003AHigh solid contentHigh effective solid contentDrilling compositionMicrosphereEngineering

The invention relates to a polyacrylamide microsphere deep profile control agent and a preparation method thereof, and mainly solves the problems that in the prior art polymer microspheres used for profile control, plugging oil displacement of medium-high-permeability oil reservoirs are poor in effects, deep profile control cannot be realized, and cost is increased by increasing of the concentration of the polymer microspheres. The polyacrylamide microsphere deep profile control agent includes the following components by weight: 0.05-0. 5 parts of a polymer microsphere emulsion, 0.1 to 1 partof an oil-displacing surfactant, and 0 to 99.85 parts of water; wherein the polymer microsphere core-shell structure comprises a core and a shell, the core is a crosslinked polymer gel microsphere containing an ionic monomer structural unit, the shell is a crosslinked polymer gel containing an ionic monomer structural unit different or same in electrical property with the ionic monomer structuralunit in the core. The polyacrylamide microsphere deep profile control agent solves the problems well and can be used for field enhanced oil recovery application such as deep profile control, water shutoff and oil displacement in the medium-high-permeability oil reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

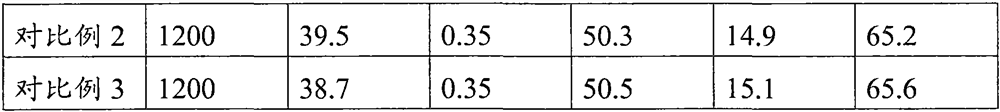

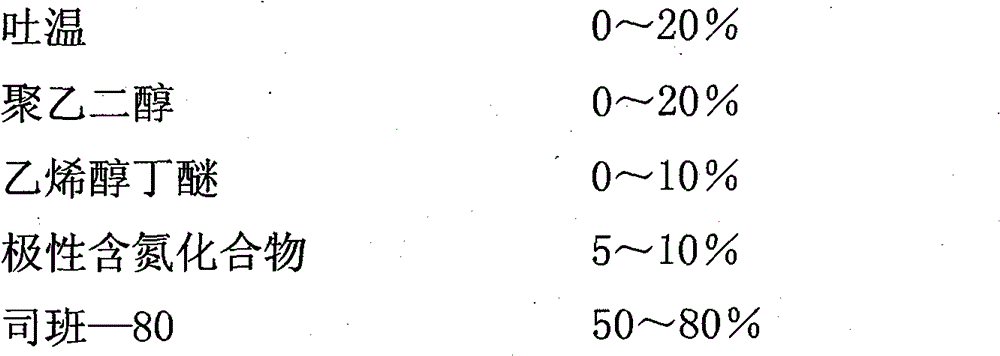

Diesel fuel pour-point depressant dispersant and preparation method thereof

ActiveCN101709233AIncreased sensitivityImprove pour point depressing effectLiquid carbonaceous fuelsFuel additivesPolyethylene glycolDepressant

The invention discloses a diesel fuel pour-point depressant dispersant and a preparation method thereof. The dispersant comprises the following components by weight percentage: 0-20% of Tween, 0-20% of polyethylene glycol, 0-10% of vinyl alcohol butyl ether, 0-10% of polar nitrogenous compounds and 50-80% of Span-80. The raw materials are weighed and mixed according to the weight percentage, and then the materials are stirred in a stirring tank with the speed of 100rpm for 30 min at the temperature of 50 DEG C, and the dispersant is prepared. In the invention, a new dispersant mixture is prepared by combining and mixing various kinds of dispersants uniformly, and then is used with the pour-point depressant according to a certain proportion, thereby improving the sensitivity of the pour-point depressant and the effect of pour point depression.

Owner:SHANGHAI INST OF TECH

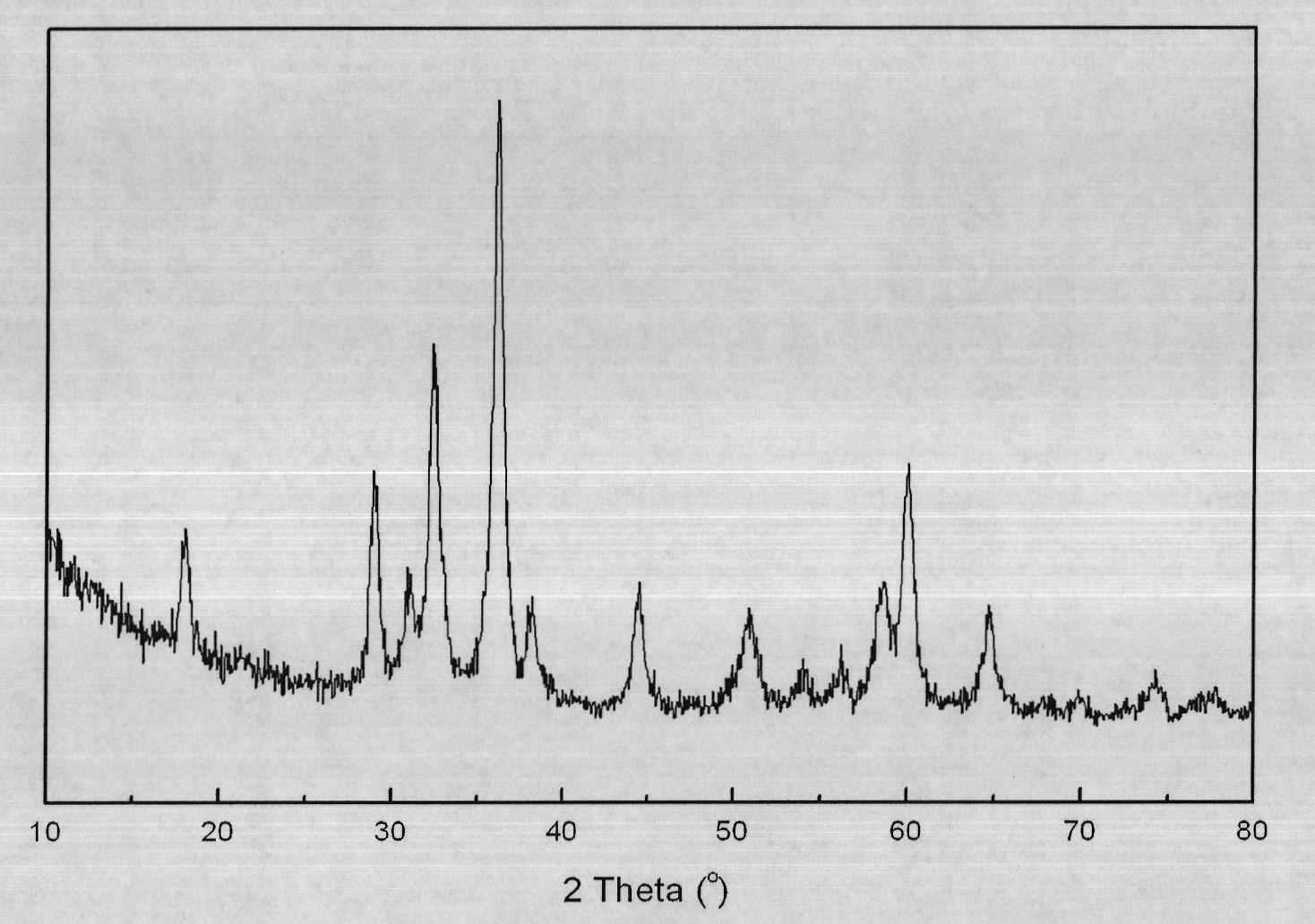

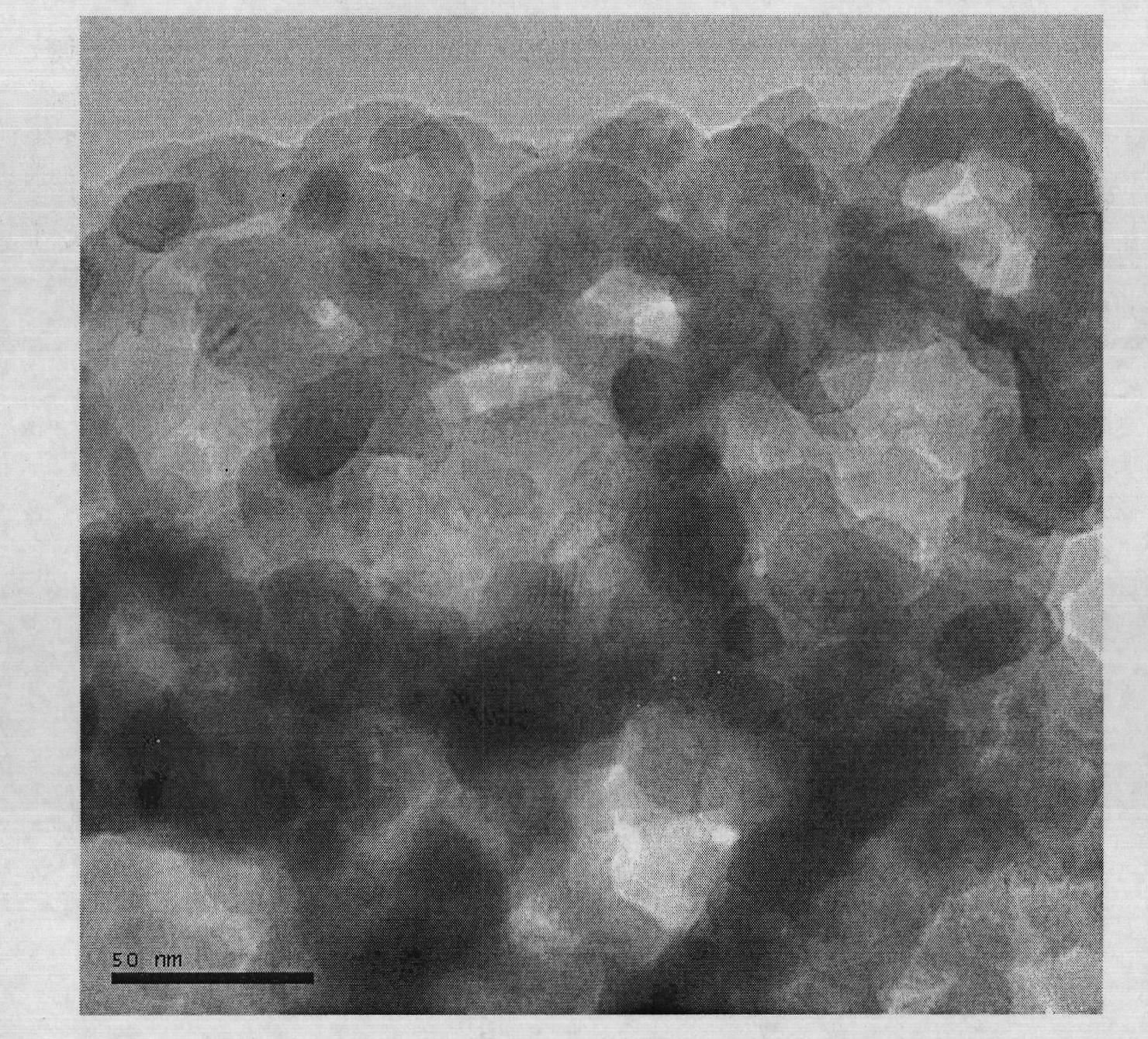

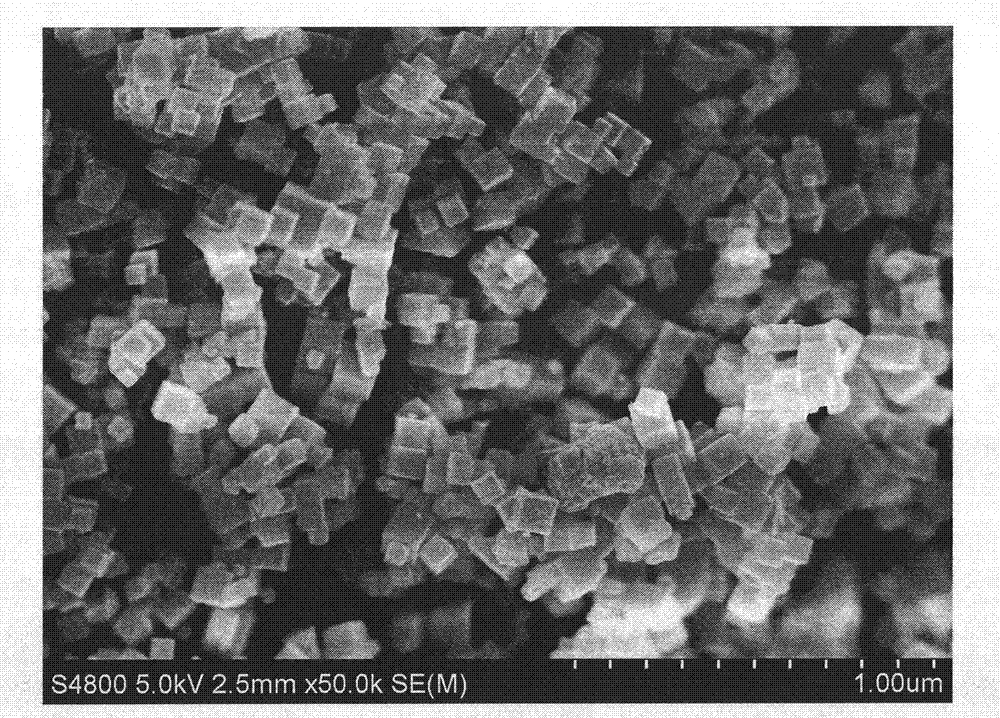

Preparation method of superfine manganese oxide

ActiveCN102464355ANot easy to coalesceStrong reductionManganese oxides/hydroxidesOrganic acidCarboxylic acid

The invention discloses a preparation method of a superfine manganese oxide. The preparation method comprises the following steps of: adding organic acid to a manganese salt solution, stirring for uniform mixing, then drying and roasting to obtain the superfine manganese oxide, wherein manganese salt is divalent soluble manganese salt, the concentration of the manganese salt solution is 20-50 percent, the organic acid is organic carboxylic acid with oxidization resistance or ascorbic acid with reducibility, wherein the molar ratio of carboxyl in the organic carboxylic acid to manganese is (1-6): 1, the molar ratio of the ascorbic acid to the manganese is (0.5-3): 1, the stirring temperature is 40-80 DEG C, and a solvent is kept to be evaporated in the range of the stirring temperature; the drying temperature is 100-120 DEG C; and the roasting temperature is 300-600 DEG C, and the roasting time is 2-10h. The preparation method disclosed by the invention has the advantages of simple production process flow and common and easily-obtained raw materials; and the prepared manganese oxide powder has the particle size of between 10nm and 60nm.

Owner:CHINA PETROLEUM & CHEM CORP +1

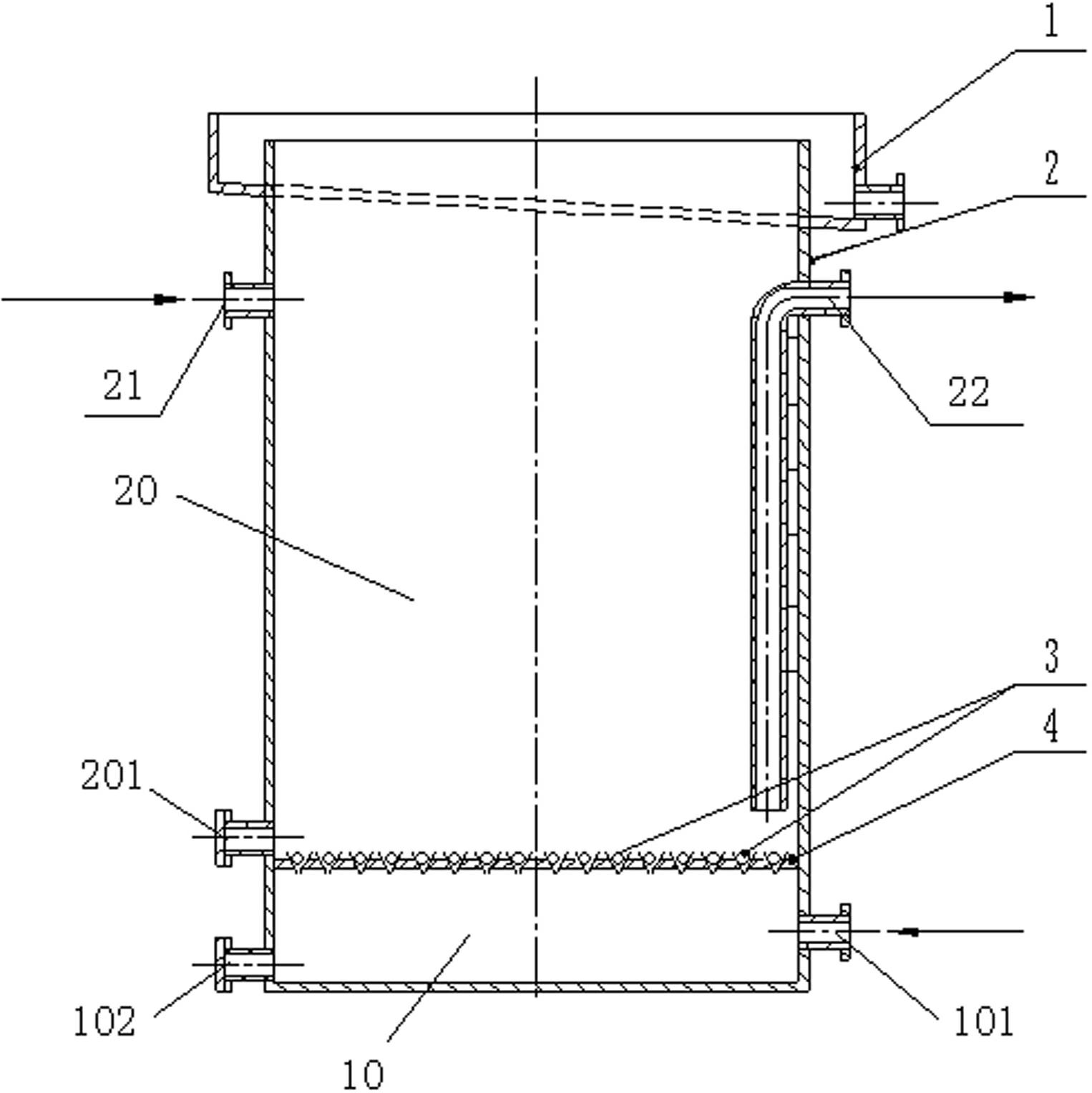

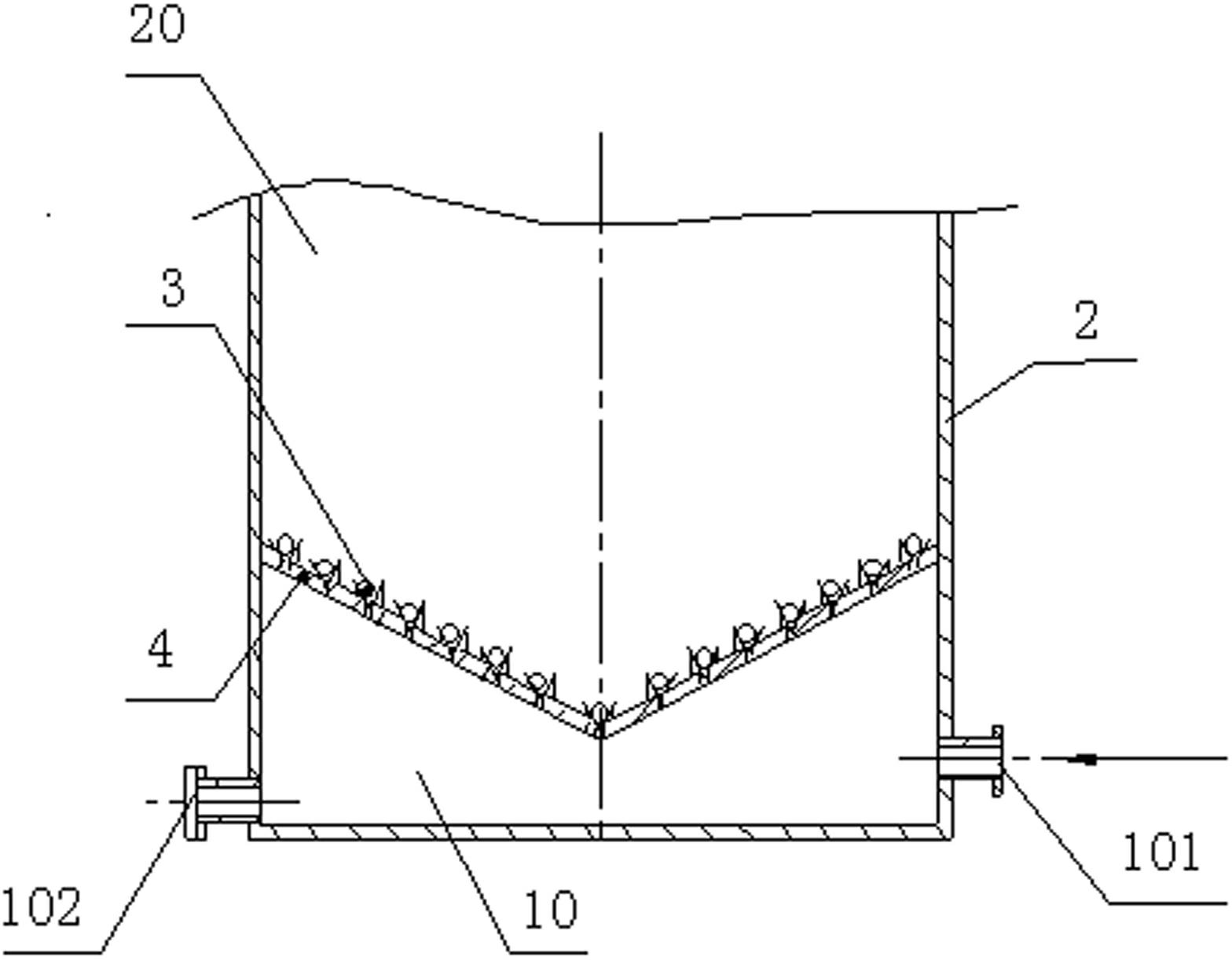

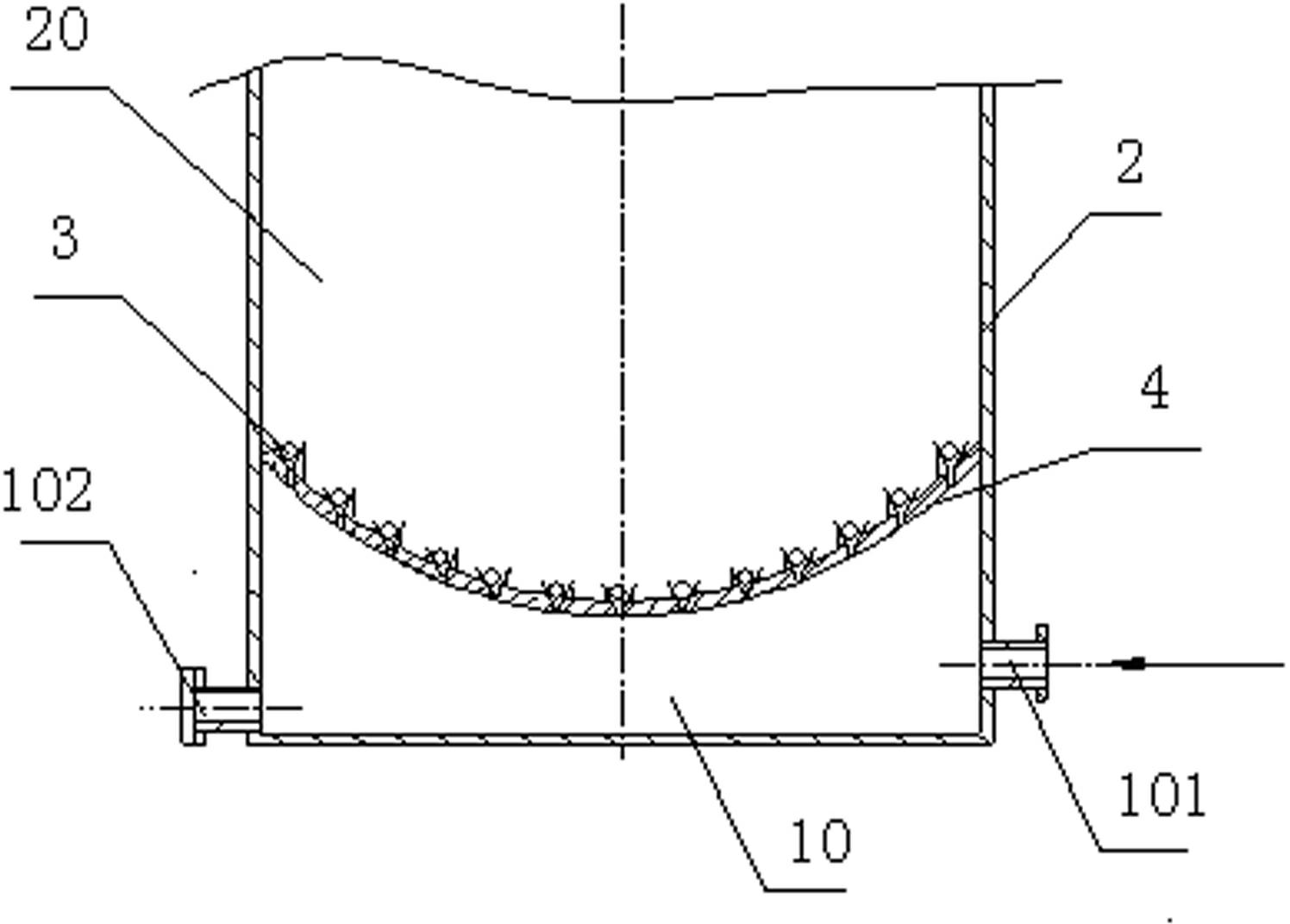

Total cross-section inflatable floatation machine

InactiveCN102211061AIncrease exposureMaximize total specific surface areaFlotationEngineeringProduct gas

The invention relates to a total cross-section inflatable floatation machine, comprising a flotation tank and a foam overflow mechanism arranged at the top of the flotation tank, wherein the tank body of the flotation tank is provided with an ore pulp inlet and an ore pulp outlet, the bottom of the tank body of the flotation tank is provided with a check valve mounting plate, and the shape of the check valve mounting plate is matched with that of the cross section of the bottom of the tank body of the flotation tank, thus the tank body of the flotation tank is divided into a pulp bearing chamber and an air chamber arranged below the pulp bearing chamber, one side of the bottom of the pulp bearing chamber is provided with an ore discharge port, one side of the air chamber is provided with an air inlet, and multiple check valves are uniformly distributed on the check valve mounting plate. The total cross-section inflatable flotation machine provided by the invention has a simple structure and is convenient to maintain, the ore dressing recovery percentage is improved, the energy consumption is reduced, gas is fully utilized, the chemical usage is reduced, the life of a quick-wear part is prolonged, the flotation process stage is shortened, and the equipment cost and investment of capital construction are reduced.

Owner:YANTAI XINHAI MINING MACHINERY

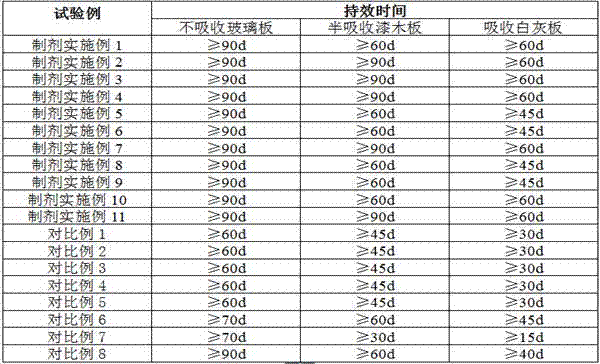

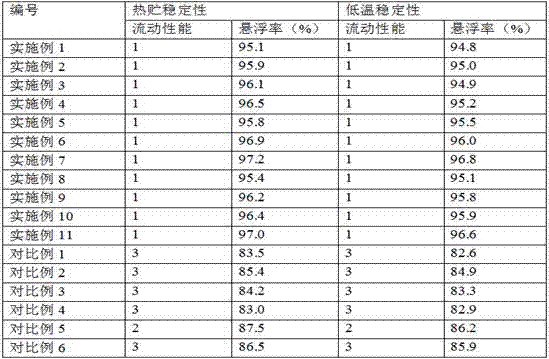

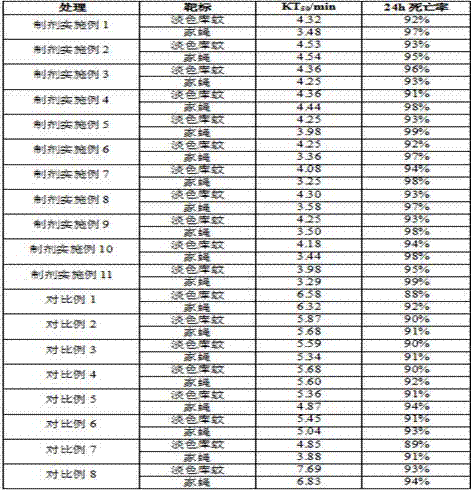

Hygienic insecticidal suspoemulsion and preparation method thereof

ActiveCN107372578AGood long-term retention activityGood fast knockdown activityBiocideDead animal preservationPreservativeActive component

The invention relates to hygienic insecticidal suspoemulsion. The suspoemulsion comprises the following components calculated in percentage by weight: 0.1 to 10% of an active component A, 0.5 to 40% of a solvent, 1.0 to 10% of an emulsifying dispersant, 1 to 30% of an active component B, 1.0 to 10% of a wetting dispersant, 0.2 to 5% of an emulsifying stabilizer, 0.05 to 10% of a thickener, 1.0 to 10% of an antifreeze agent, 0.1 to 1.0% of a defoamer, 0.1 to 1.0% of a preservative, 0.1 to 5.0% of an acid-base regulator, and the balance of water; the active component A is knockout pyrethroid; the active component B is fatal pyrethroid; the emulsifying stabilizer is a ultra-high molecular weight copolymer of which the relative molecular weight is 1 to 20 million; in the suspoemulsion, the emulsifying dispersant and the wetting dispersant are optimized, especially the special emulsifying stabilizer is supplemented to solve the stability problem existing in a suspoemulsion system.

Owner:江苏功成生物科技有限公司

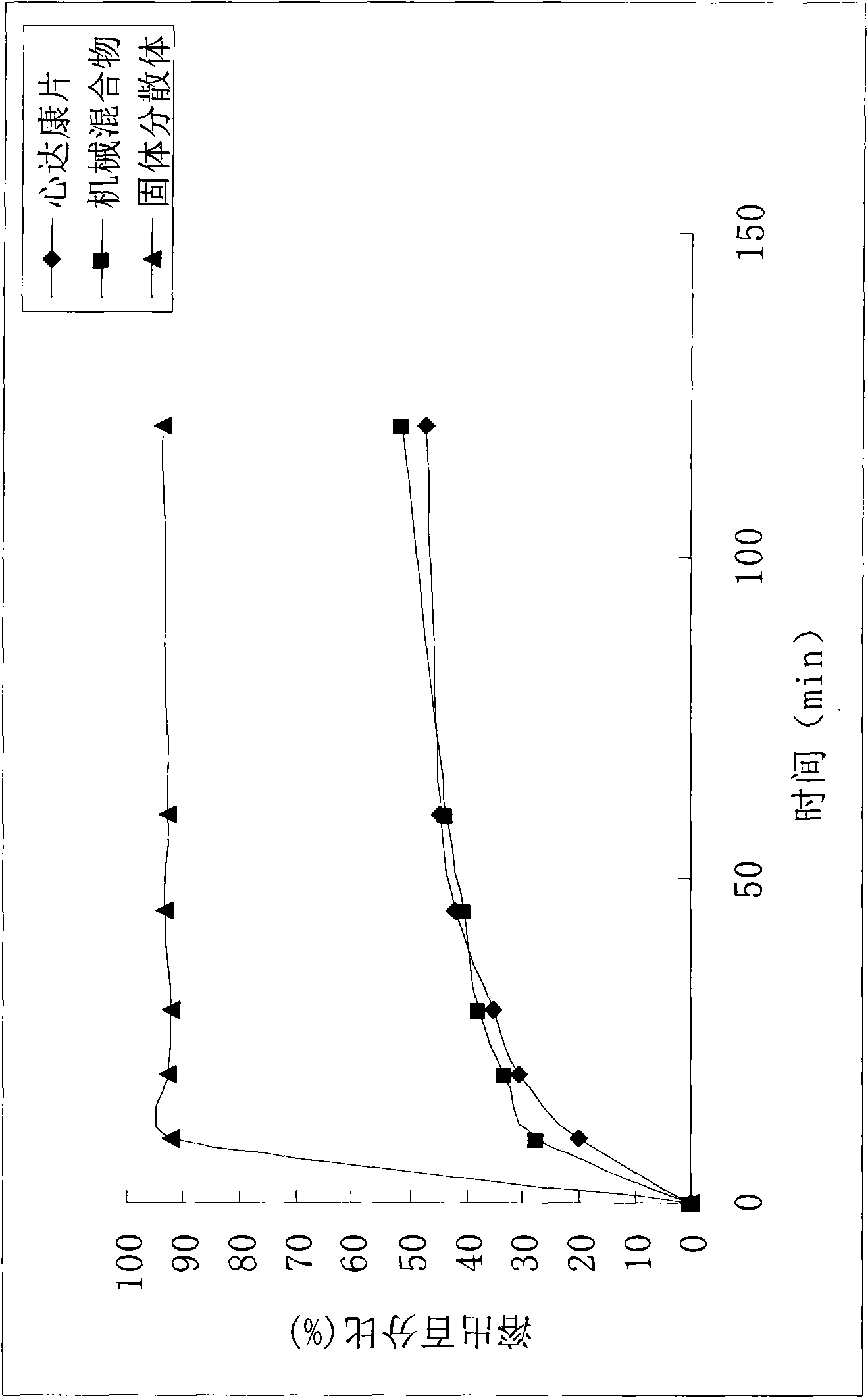

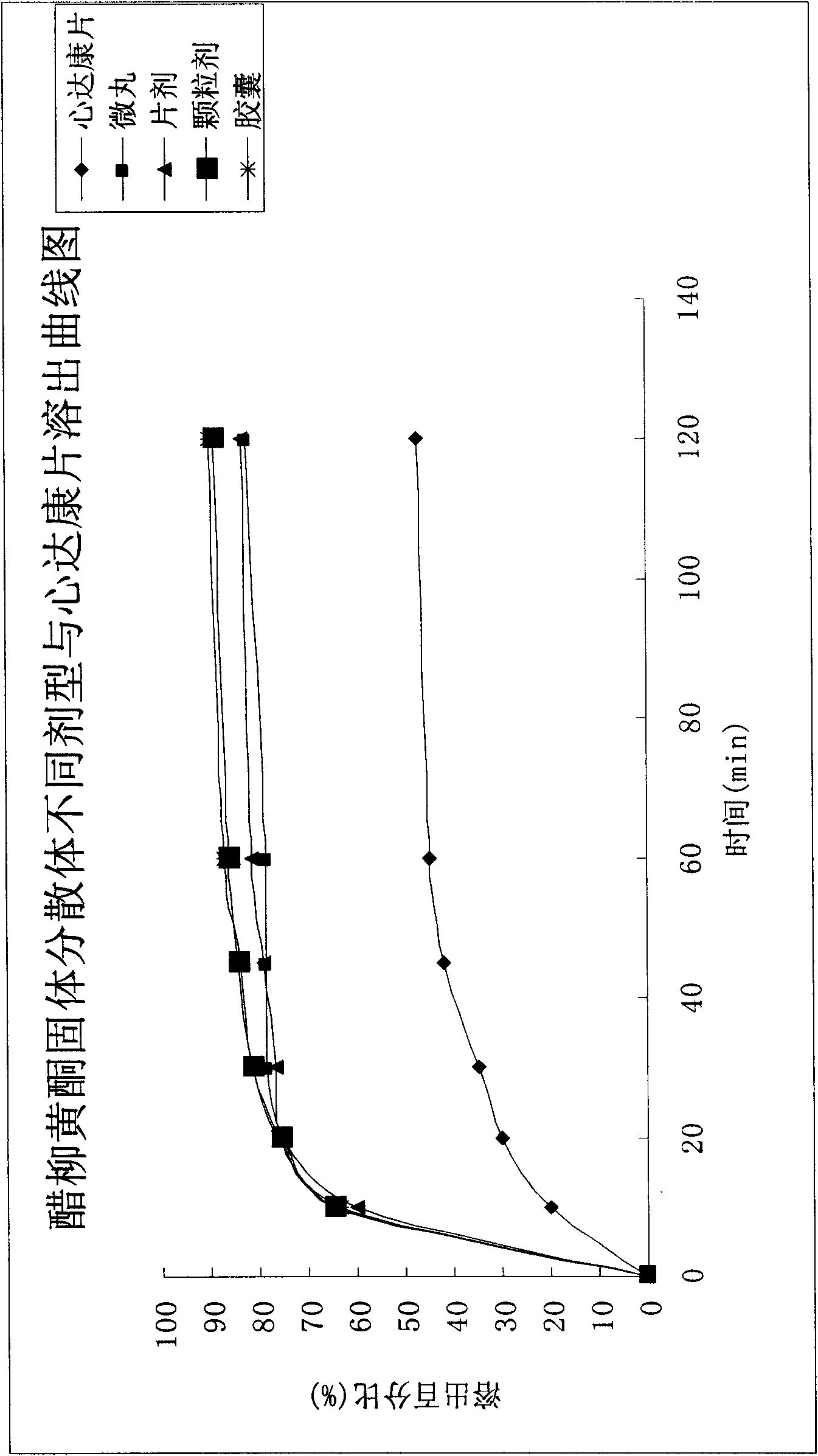

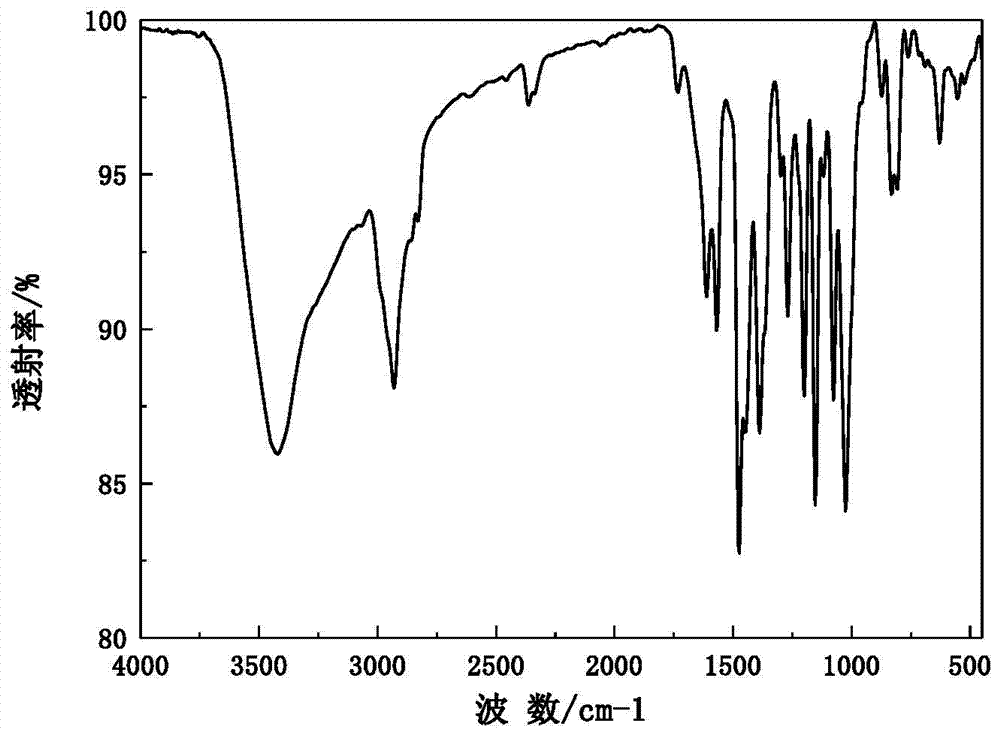

Flavone acetylsalicylate solid dispersion and preparation method thereof

InactiveCN101574380AGood dispersionIncrease the dissolution surface areaMetabolism disorderAntinoxious agentsEnhanced bioavailabilityDrug Dissolution

The invention discloses flavone acetylsalicylate solid dispersion. The dispersion is prepared by preparing the flavone acetylsalicylate and a hydrophilic carrier, wherein the weight ratio of the flavone acetylsalicylate and the hydrophilic carrier is between (1:1) and (1:10). The insoluble flavone acetylsalicylate is highly dispersed in the strong hydrophilic carrier, so the invention can not only maintain the highly-dispersed state of insoluble drugs, and but also enables the drugs to have good wettability to be produced to be the preparation capable of improving drug solubility, quickening drug dissolution velocity and improving bioavailability. In addition, the invention also discloses a method for preparing the flavone acetylsalicylate solid dispersion.

Owner:SHANGHAI UNIV OF T C M +1

Preparation method of modified nano calcium carbonate for PVC automobile primer

The invention discloses a preparation method of modified nano calcium carbonate for PVC automobile primer. The preparation method comprises the steps that calcium chloride powder is added into an alcohol compound, and then water, polyoxyethylene ether, a cellulose derivative and glycerin monostearate are added to prepare calcium chloride microemulsion; sodium carbonate is added into water, and then the alcohol compound and fatty acid saponified liquid are added to prepare calcium carbonate microemulsion; calcium carbonate microemulsion is slowly added into the calcium chloride microemulsion, then a aldehyde compound is added and stirred to be mixed with the liquid, and sediment appears; the sediment is separated by a centrifugal machine, and modified nano calcium carbonate serous fluid isobtained; and the modified nano calcium carbonate serous fluid is dried and smashed, and the surface modified nano calcium carbonate product is obtained. The produced material method is simple and convenient, and has the very good compatibility with PVC. The produced primer has the good thixotropic property, can resist abrasion and chemical corrosion, and has the good stone chip resistance. The primer has the high viscosity when being stored, is easy to spray and level when being coated.

Owner:广西南宁桂尔创环保科技有限公司

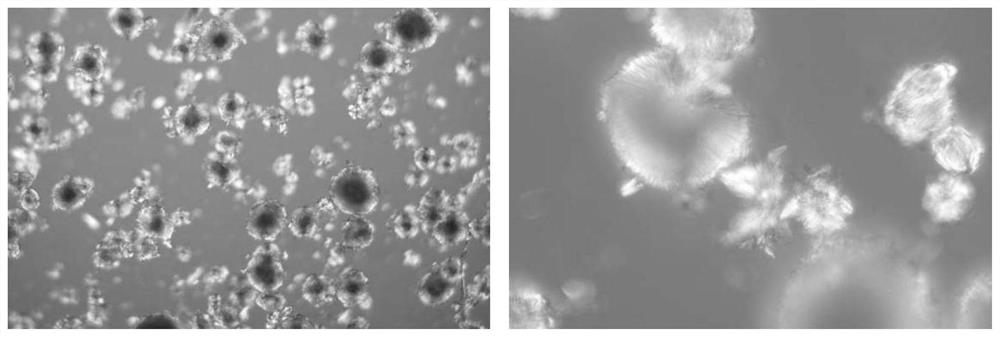

Polyacrylamide microsphere emulsion and preparation method thereof

The invention relates to submicron polyacrylamide microsphere emulsion with high solid content and high stability as well as a preparation method thereof. The problems in the prior art that the use amount of an emulsifier in preparation of the polyacrylamide microsphere emulsion by a reversed-phase microemulsion method as well as the solid content is slightly low and the stability is low in preparation of a product by the common reversed-phase emulsion method are mainly solved. According to the technical scheme which adopts a composite emulsifier system and a composite initiator, the polyacrylamide microsphere emulsion is prepared by polymerizing: a) 10 to 40 parts by weight of an oil phase, b) 1 to 8 parts by weight of a composite emulsifier system, c) 50 to 80 parts by weight of an aqueous phase containing a polymerization monomer, wherein the content of the polymerization monomer in the aqueous phase is 40 to 70 percent, and d) 0.01 to 1.0 part of reversed-phase emulsion system suchas a crosslinking agent, so that the problems are solved well, and the polyacrylamide microsphere emulsion can be applied to field application capable of increasing recovery ratio, such as profile modification in depth, water plugging and oil displacement for tertiary oil recovery of medium-low permeability oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

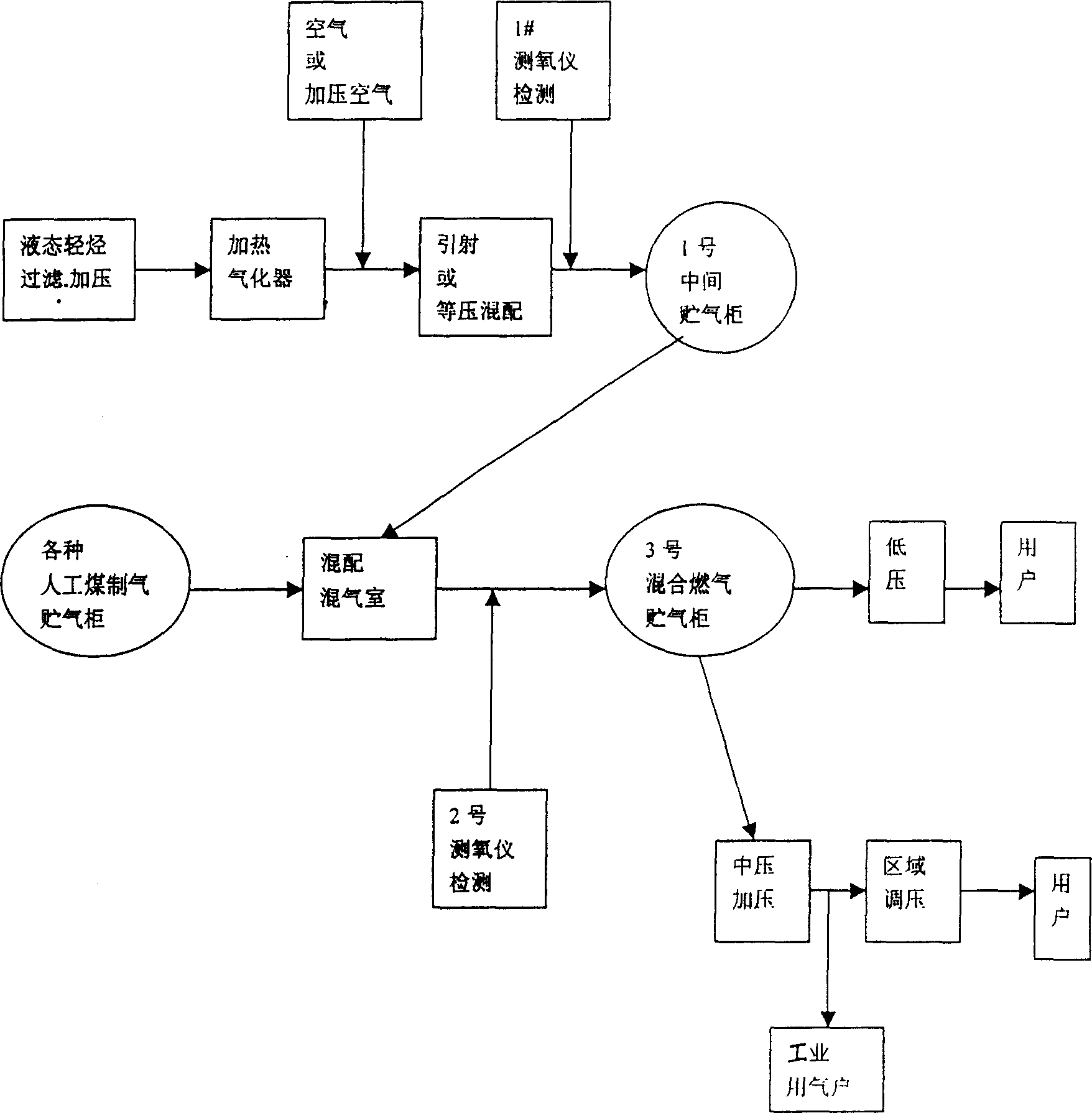

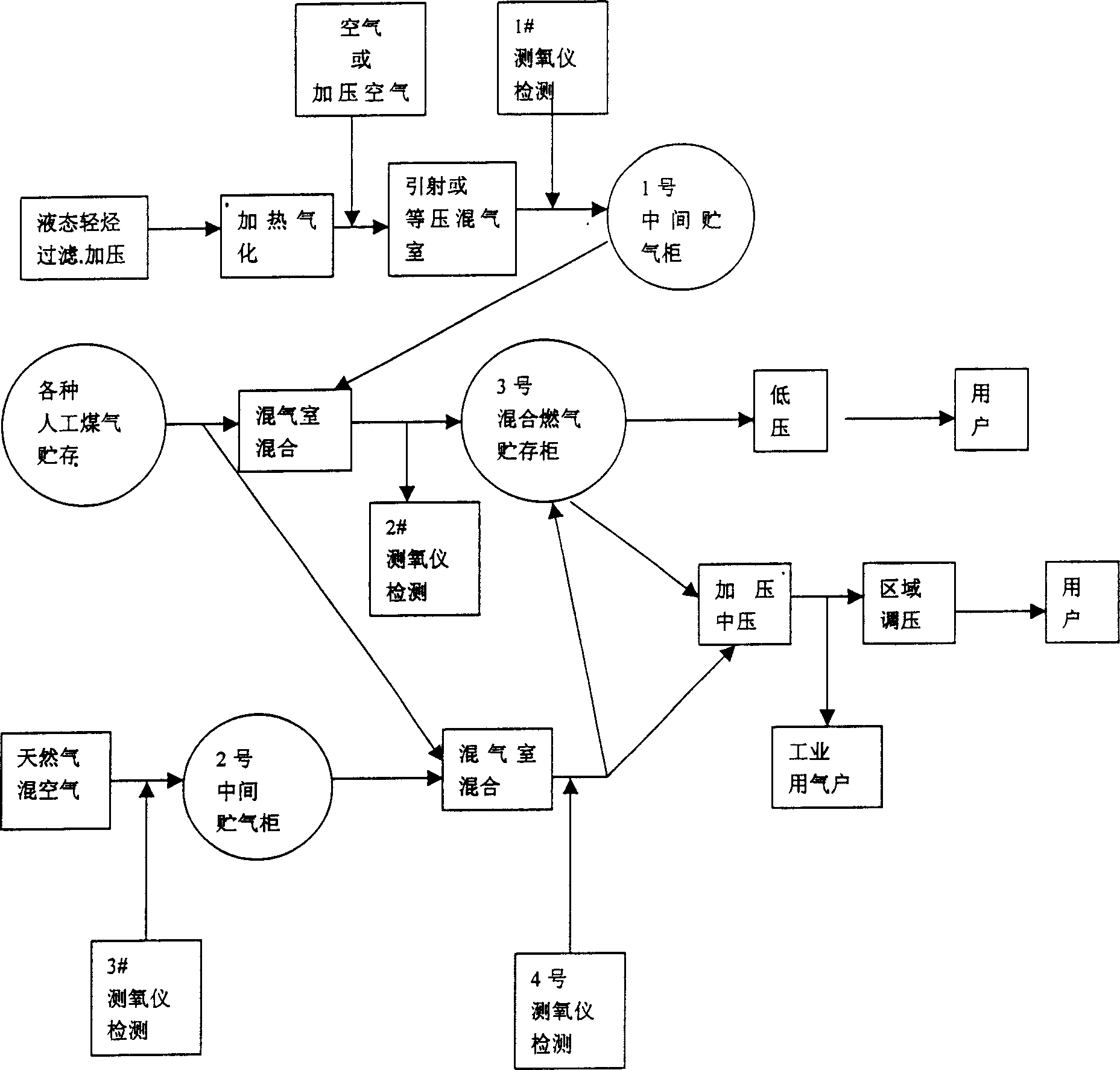

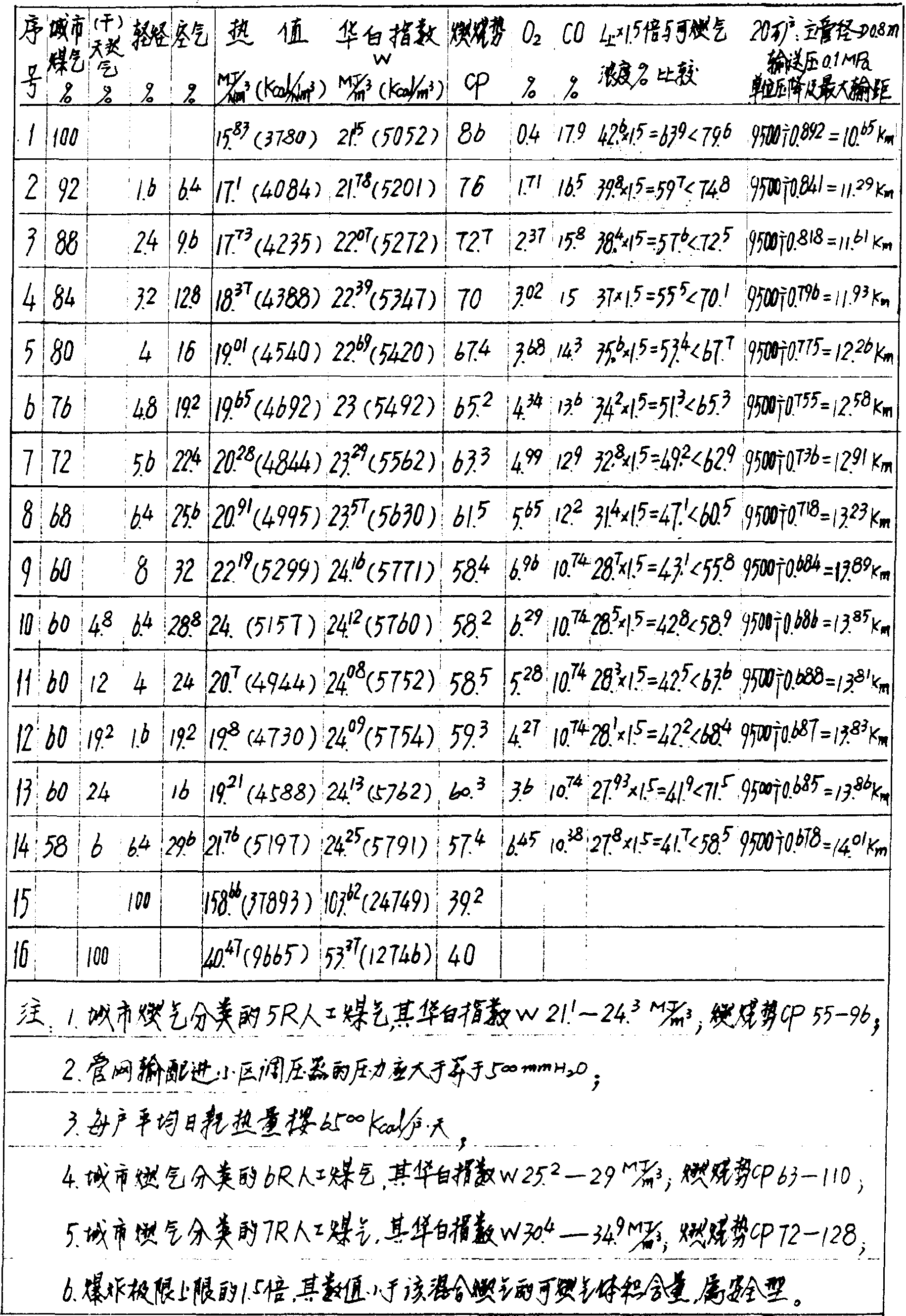

Production of mixed urban gas with light-hydrocarbon gas and coal gas blending

InactiveCN1896193AReduce the burden onReduce financial subsidiesGaseous fuelsGas modification by gas mixingAtmospheric airProcess engineering

Production of urban mixed gas from mixed light hydrocarbon gas blended coal is carried out by filtering liquefied light hydrocarbon, pressurizing, heat vaporizing in heating vaporizer, mixing vaporized light-hydrocarbon gas with air or pressurized air in mixing chamber to form mixed light hydrocarbon, inspecting mixed light-hydrocarbon by oxygen inspector, storing in intermediate air tank, mixing coal-made air with mixed light hydrocarbon in mixing chamber to form mixed gas, inspecting mixed gas by oxygen inspector, storing in air tank, low or low-mediate pressure two-stage transfer distributing for mixed gas and entering into user terminal. It has less carbon monoxide content.

Owner:SHANGHAI LIANXIANG REAL ESTATE

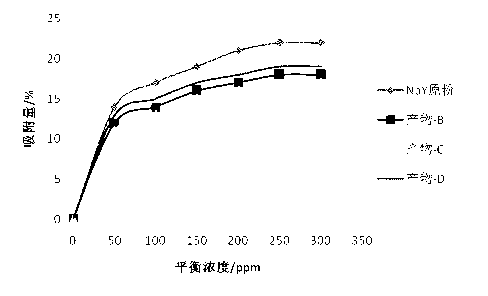

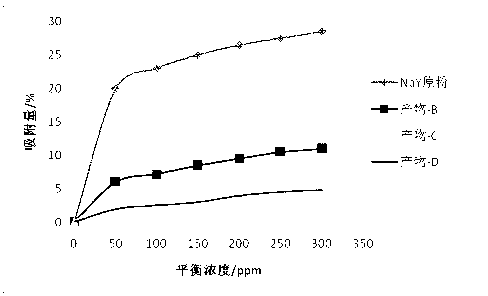

Hydrophobic modification method for Y-shaped molecular sieve

ActiveCN102320621BImprove hydrophobicityNot easy to coalesceFaujasite aluminosilicate zeoliteMolecular sieveWater vapor

Owner:广东科艺普实验室设备研制有限公司 +3

Novel nano solid super-strong alkali catalyst and preparation and application thereof

Owner:HUNAN UNIV

Method for synthesis of nano cerium zirconium solid solution through microemulsion method

InactiveCN105344346ASimple and fast operationSimple stepsHeterogenous catalyst chemical elementsCatalyst activation/preparationCerium nitrateAlcohol

The invention relates to a method for synthesis of nano cerium zirconium solid solution through a microemulsion method. The concrete operation steps of the method are as follows: firstly, a mixed solution of hexadecyl trimethyl ammonium bromide,n-butanol and cyclohexane is prepared, and the mixed solution is divided into two parts evenly for standby; secondly, one part of the mixed solution obtained in the first step is added into a mixed solution of cerium nitrate and zirconium oxynitrate and microemulsion A is prepared; thirdly, the other part of the mixed solution obtained in the first step is added into ammonium hydroxide and microemulsion B is prepared; fourthly, the microemulsion A and the microemulsion B are mixed with violent stirring, and the mixture is subjected to aging for 12h at a room temperature; fifthly, the mixture obtained in the fourth step is filtered, the obtained aged material is washed in deionized water and absolute ethyl alcohol, dried for 2h at a temperature of 110 DEG C, and calcined for 2h at a temperature of 500 DEG C and nano cerium zirconium solid solution is obtained. Operation is simple, steps are simple, cerium zirconium solid solution with a high specific surface area can be obtained in a short time, and the method is suitable for industrial production.

Owner:刘义林

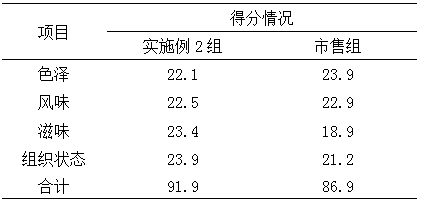

Preparation method of high-emulsion stable soy proteins

InactiveCN103583791AGood dispersionImprove subsequent processing efficiencyVegetable proteins working-upEmulsionChemical compound

The invention discloses a preparation method of high-emulsion stable soy proteins, belongs to the food processing field, and relates to a method for preparing high-emulsion stable soy proteins through ultrasonic-alkylated modification. The method is as follows: (1) ultrasonic modification: soy proteins are prepared to a soy protein solution with a certain concentration, and are modified by ultrasonic waves; (2) alkylated modification: the soy protein solution of the step (1) is added with benzaldehyde and a freshly prepared NaBH3CN solution for implementing alkylated reaction; (3) dialysis: the soy protein solution of the step (2) is dialyzed at the temperature of 4 DEG C; and (4) drying: the soy protein solution of the step (3) is sprayed and dried to obtain high-emulsion stable soy protein products. The emulsibility of the soy proteins prepared through the physical and chemical compounded modification is 0.894-0.978, and the emulsifying stability thereof can achieve 60.04-63 min; the emulsibility and the emulsifying stability of the soy proteins of the invention are improved for 124-145% and 195-210% compared with that of the non-modified soy proteins; and the preparation method has short production period and low production cost.

Owner:SOYBEAN TECH DEV RES CENT HEILONGJIANG PROV

Micro emulsion nanometer drilling fluid for stable unconventional reservoir

InactiveCN109943299AImproved rheological propertiesReduce frictionDrilling compositionEmulsionXanthan gum

The invention discloses a micro emulsion nanometer drilling fluid for the stable unconventional reservoir. The drilling fluid is prepared from, by weight, 100-150 parts of water, 1-3 parts of bentonite, 0.5-1 part of sodium carbonate, 0.5-1 part of sodium hydroxide, 1-2 parts of a micro emulsion, 0.1-0.3 part of xanthan gum, 0.5-1 part of a fluid loss agent, 0.5-1.5 parts of a blocking agent and 0.5-1 part of a lubricating agent. The drilling liquid has the advantages that the rheological property of the drilling liquid is improved, and the filter loss is reduced.

Owner:BEIJING DADE GUANGYUAN PETROLEUM TECH SERVICE

Preparation method of soybean protein isolate emulsifier

InactiveCN108095049AImprove water solubilityImprove emulsificationFood ingredient as emulsifierProtein proteinEmulsion

The invention relates to a preparation method of a soybean protein isolate emulsifier and belongs to the technical field of emulsifiers. Free amino acids or amino groups of protein molecules are linked with reducing sugar by utilizing covalent bonds to form a sugar-protein polymer, the copolymer can be closely absorbed on an oil-water interface by virtue of the hydrophobic property of protein, anda thick protective film can be formed on droplet surfaces in an emulsion, thereby inhibiting the phenomena of precipitation, flocculation, aggregation and the like among droplets in the emulsion system so as to enable the emulsion system to be stable; furthermore, the copolymer can be well dissolved in the emulsion system by virtue of the hydrophilic property of polysaccharides, so that rheological properties of the emulsion can be controlled; and copolymer molecules can form a reticular space structure in continuous phases, so that phase separation and emulsion layering caused by gravity canbe delayed so as to enable the copolymer emulsion system to be stable.

Owner:常州五荣化工有限公司

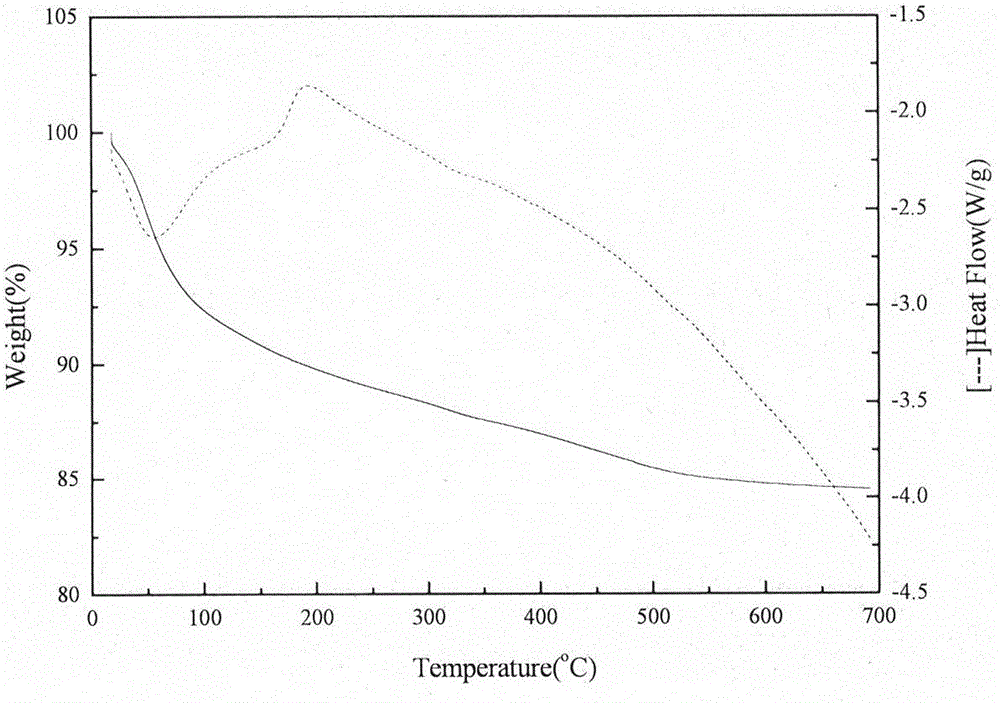

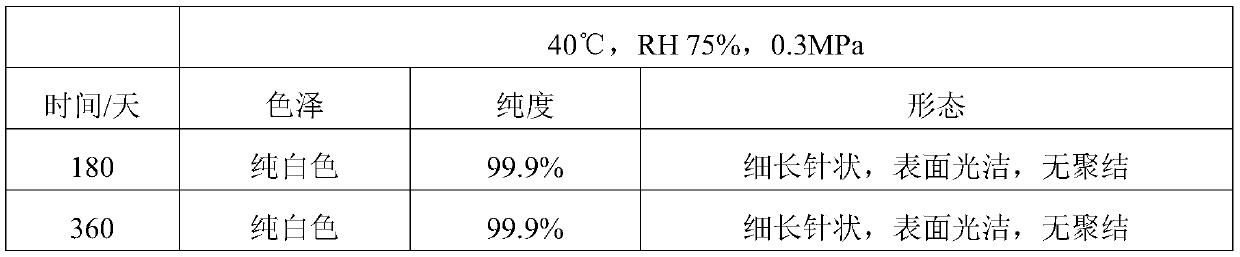

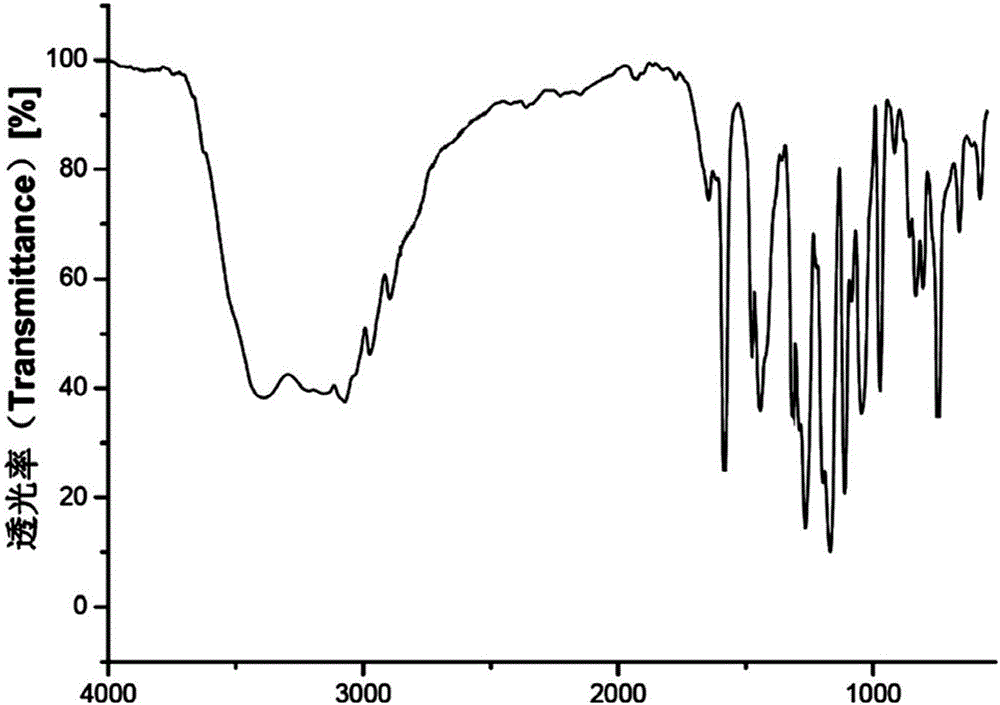

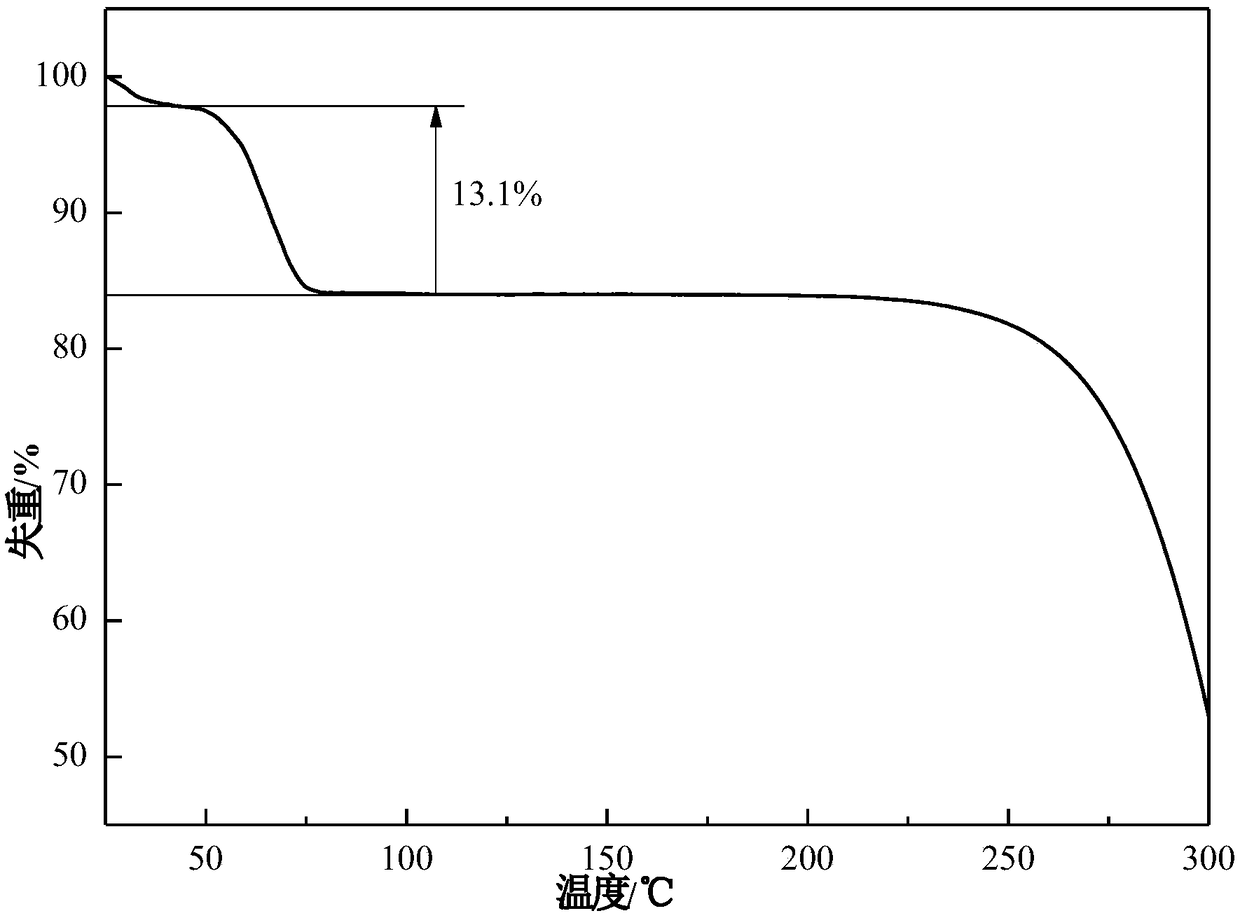

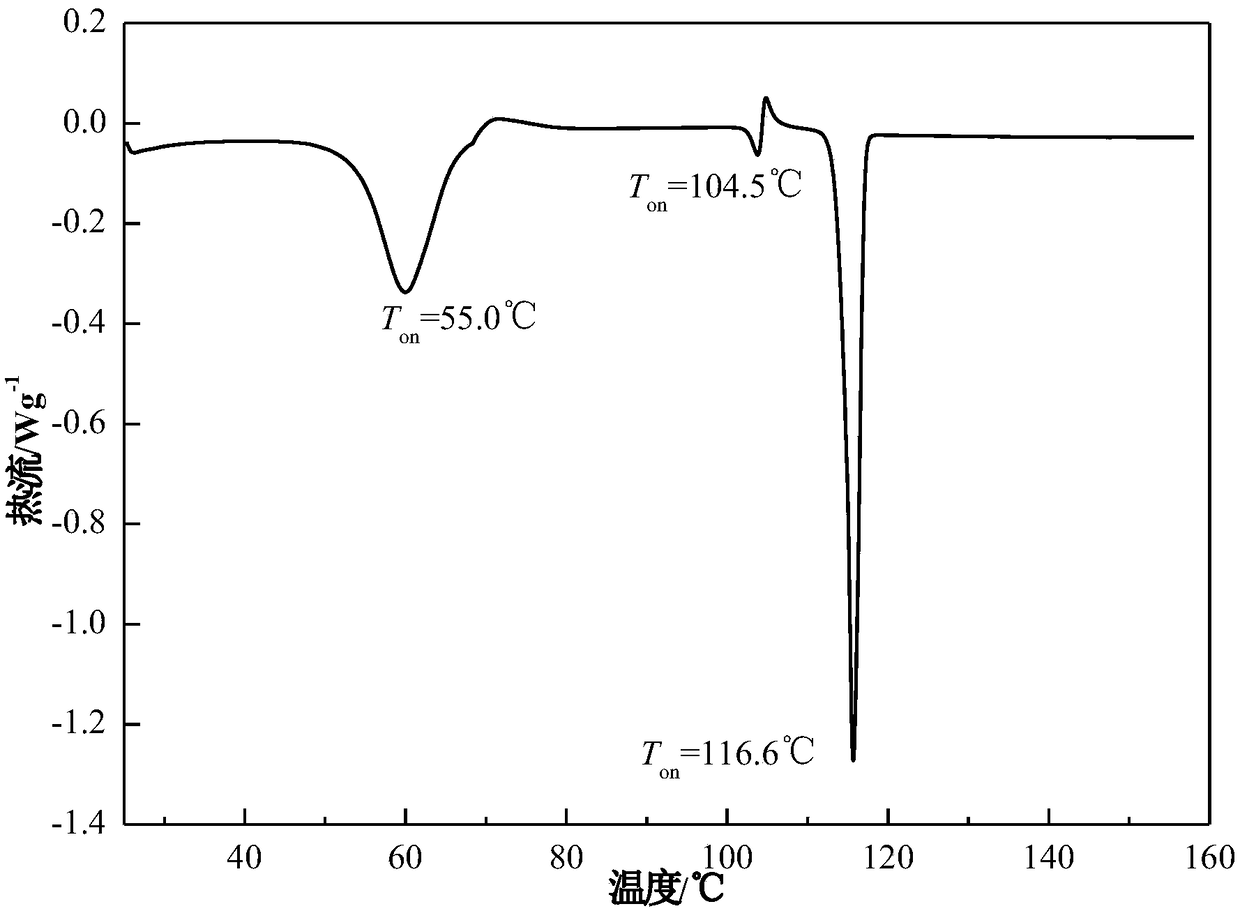

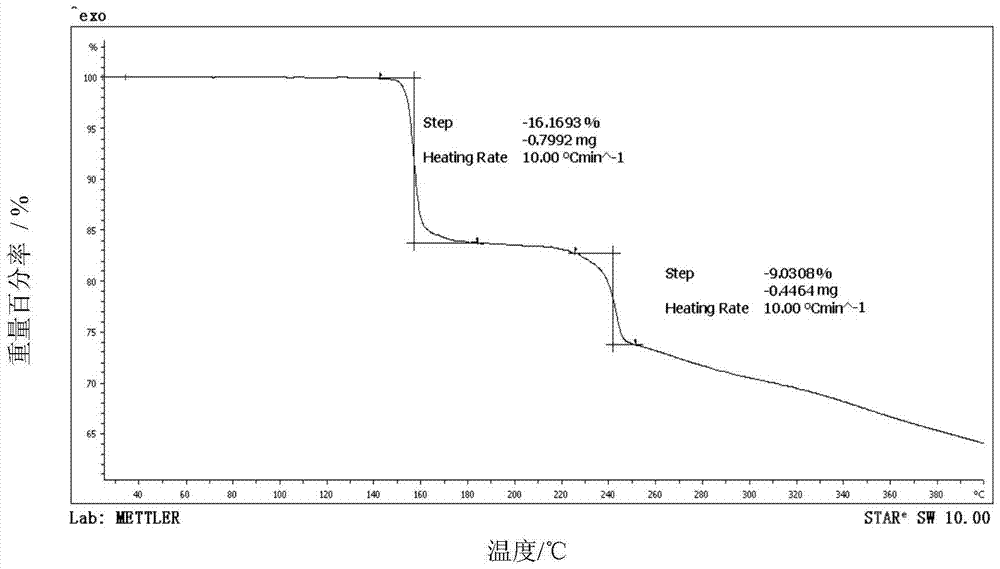

Preparation method of prothioconazole I-type crystal form

PendingCN110981822AFast preparationEasy to manufactureOrganic chemistry methodsSolvent evaporationPhysical chemistry

The invention relates to the field of compound crystal forms, in particular to a preparation method of a prothioconazole I-type crystal form. The preparation method comprises the following steps: dissolving a prothioconazole raw material in a solvent, filtering to obtain filtrate, standing the filtrate and separating out a solid phase, namely the prothioconazole I-type crystal form. According to the technical scheme, the prothioconazole I-type crystal form is prepared through a solvent evaporation method and a cooling method, the method is simple and easy to implement and low in cost, and theprepared product is high in yield and purity, good in stability without coalescence and suitable for being applied to industrial production.

Owner:HAILIR PESTICIDES & CHEM GRP

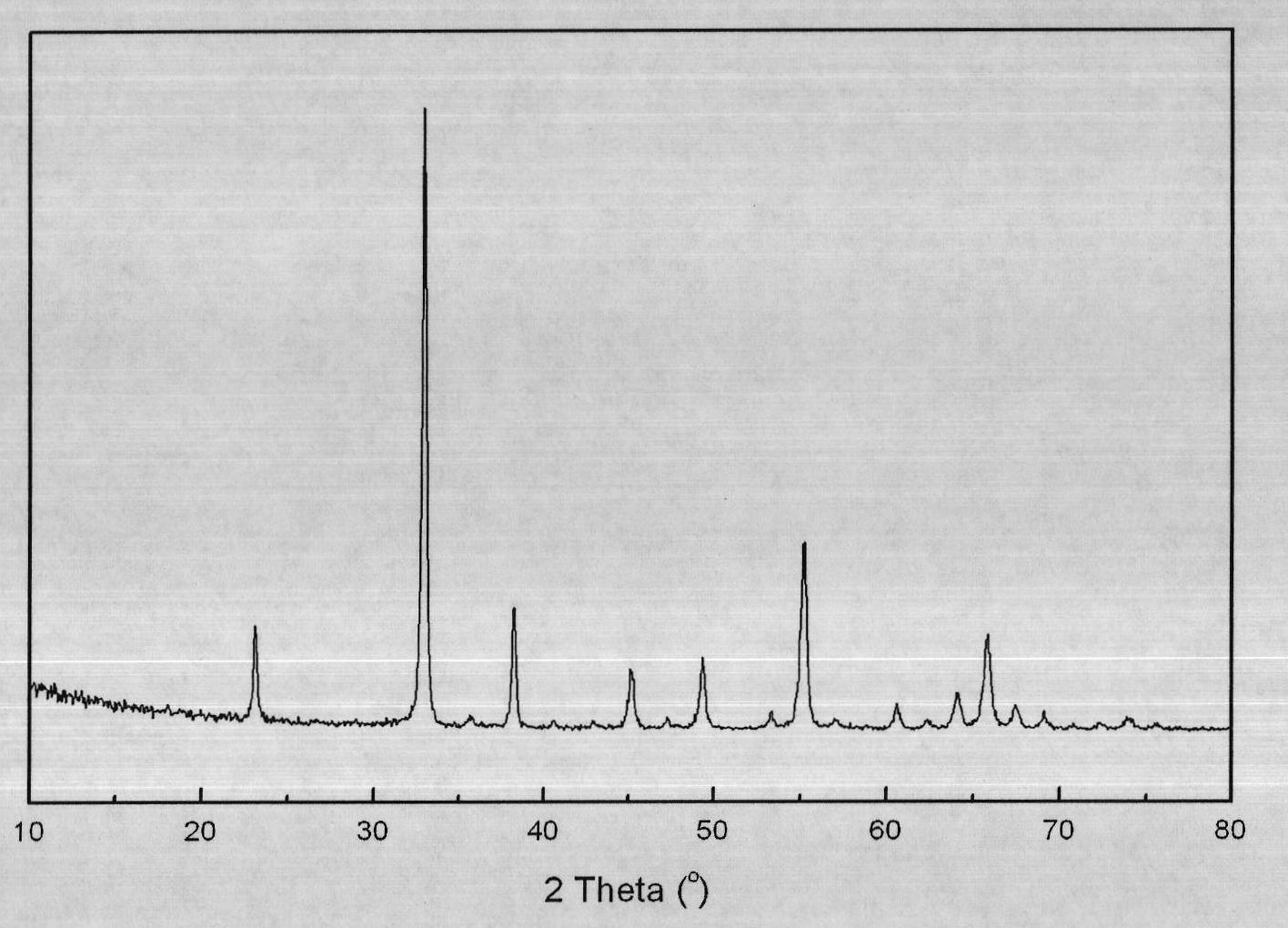

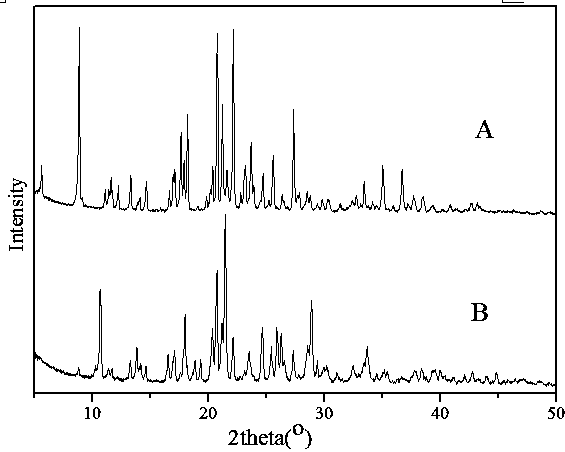

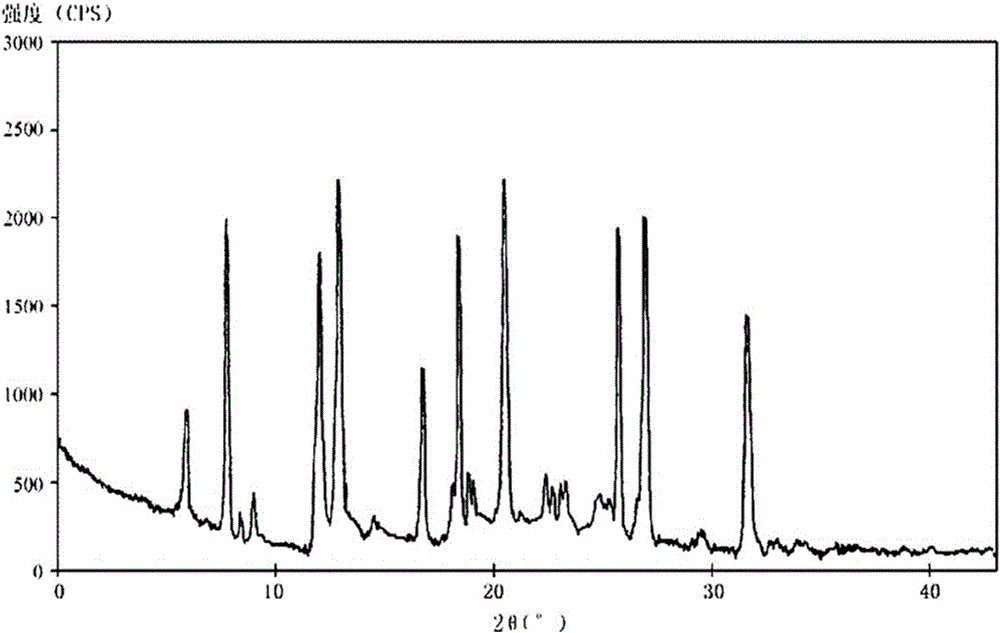

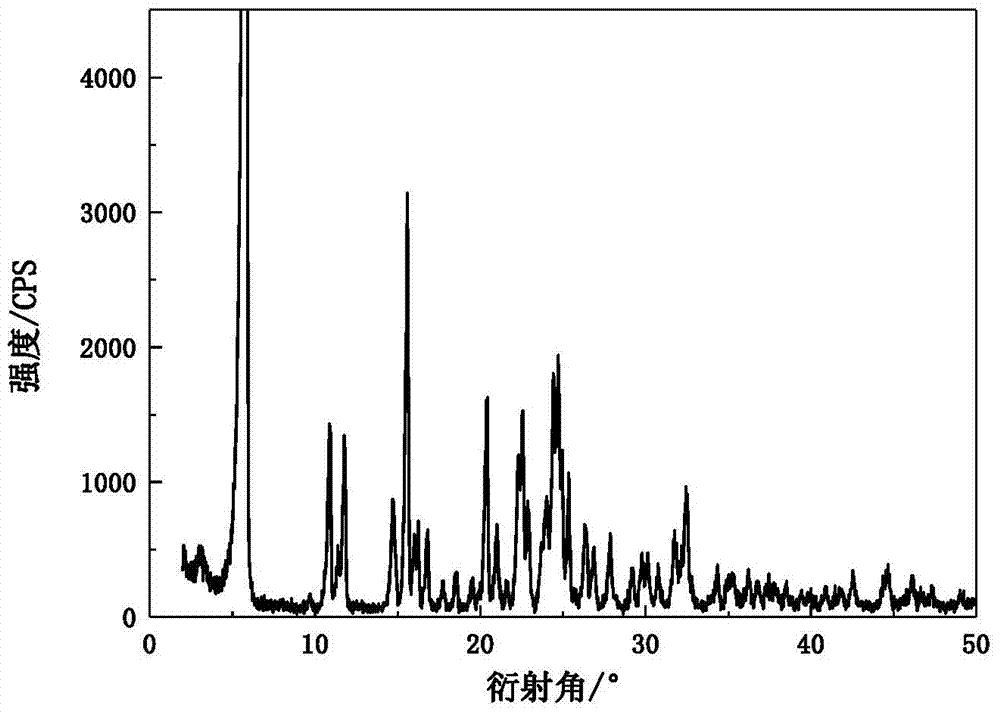

New crystal form of (R)-Lansoprazole sodium and preparation method thereof

ActiveCN106749186AModerate granularityImprove liquidityAntibacterial agentsOrganic active ingredientsCrystallographyAntioxidant

The invention discloses a new crystal form A of a (R)-Lansoprazole sodium dimethylacetamide solvate and a preparation method thereof. The powder X-ray diffraction spectrum has the feature diffraction peak in the position where the diffraction angle 2Theta is 5.9, 7.6, 12.2, 12.7, 16.6, 18.4, 20.5, 25.8, 26.8 and 31.4 degrees. The preparation method for the new crystal form A comprises the following steps: adding the (R)-Lansoprazole sodium to a mixed solvent of the dimethylacetamide and water, adding the suitable amount of a viscosity modifier and an antioxidant, adding a poor solvent after dissolving and clarifying, and slowly crystallizing to obtain the new crystal form A. The new crystal form A of the (R)-Lansoprazole sodium dimethylacetamide solvate has the advantages of moderate crystal granularity, good mobility, difficult aggregation and degradation, and good stability, and is suitable for the hot-melting extrusion process. The preparation process of the new crystal form A is simple, the cost is low, the yield is high, the solvent is safe and non-toxic, and the new crystal form A is suitable for the industrial production.

Owner:NANJING HERON PHARM CO LTD +1

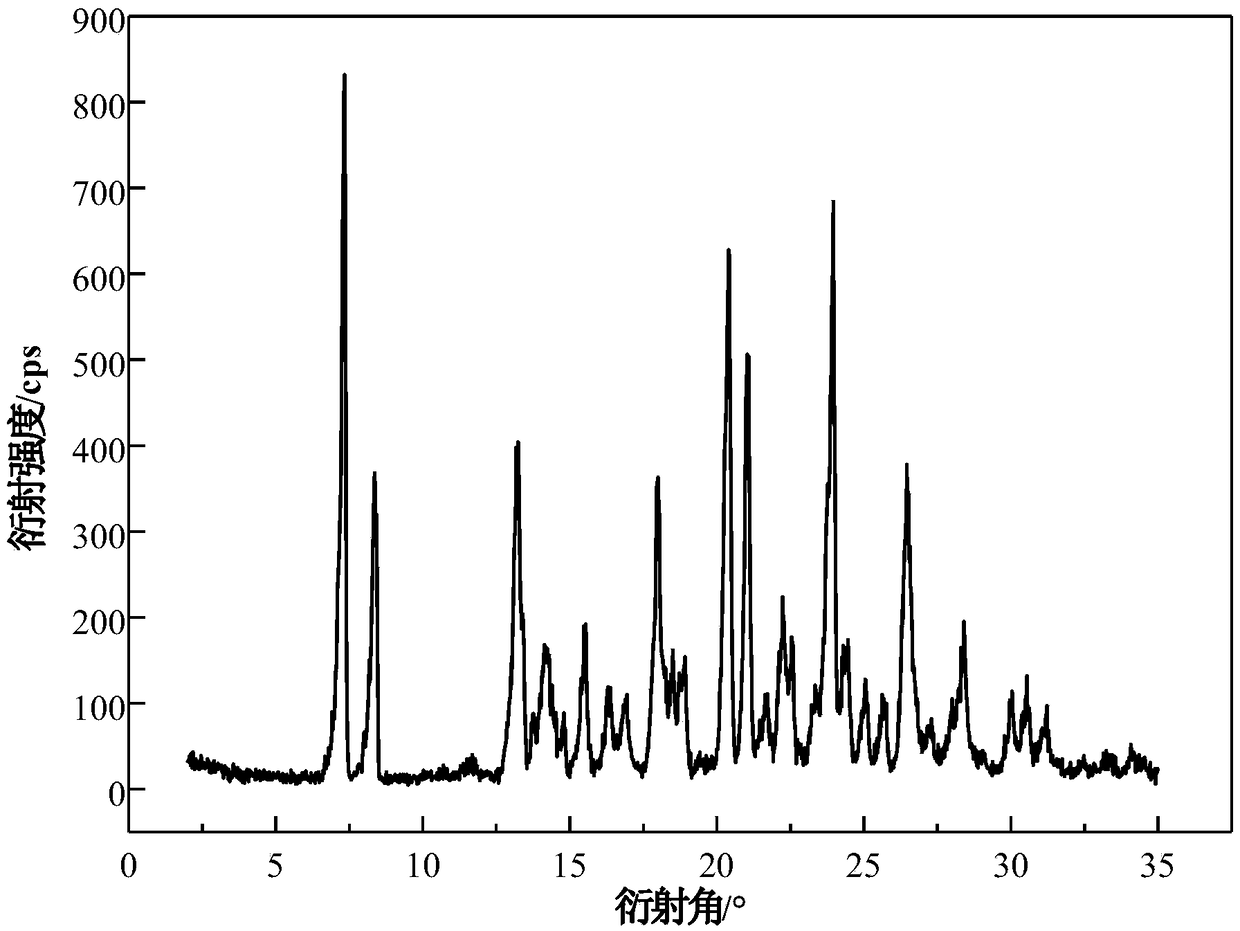

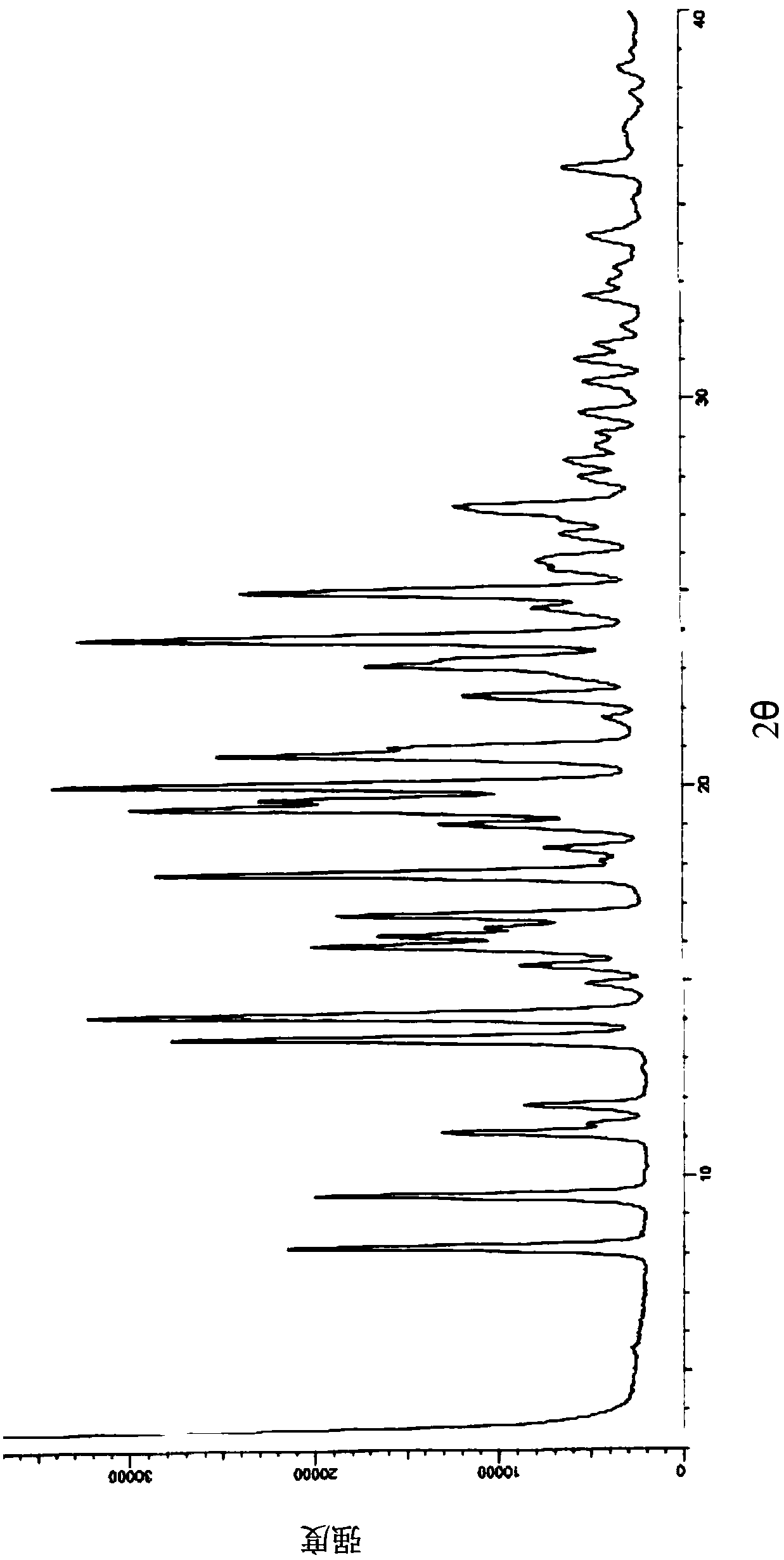

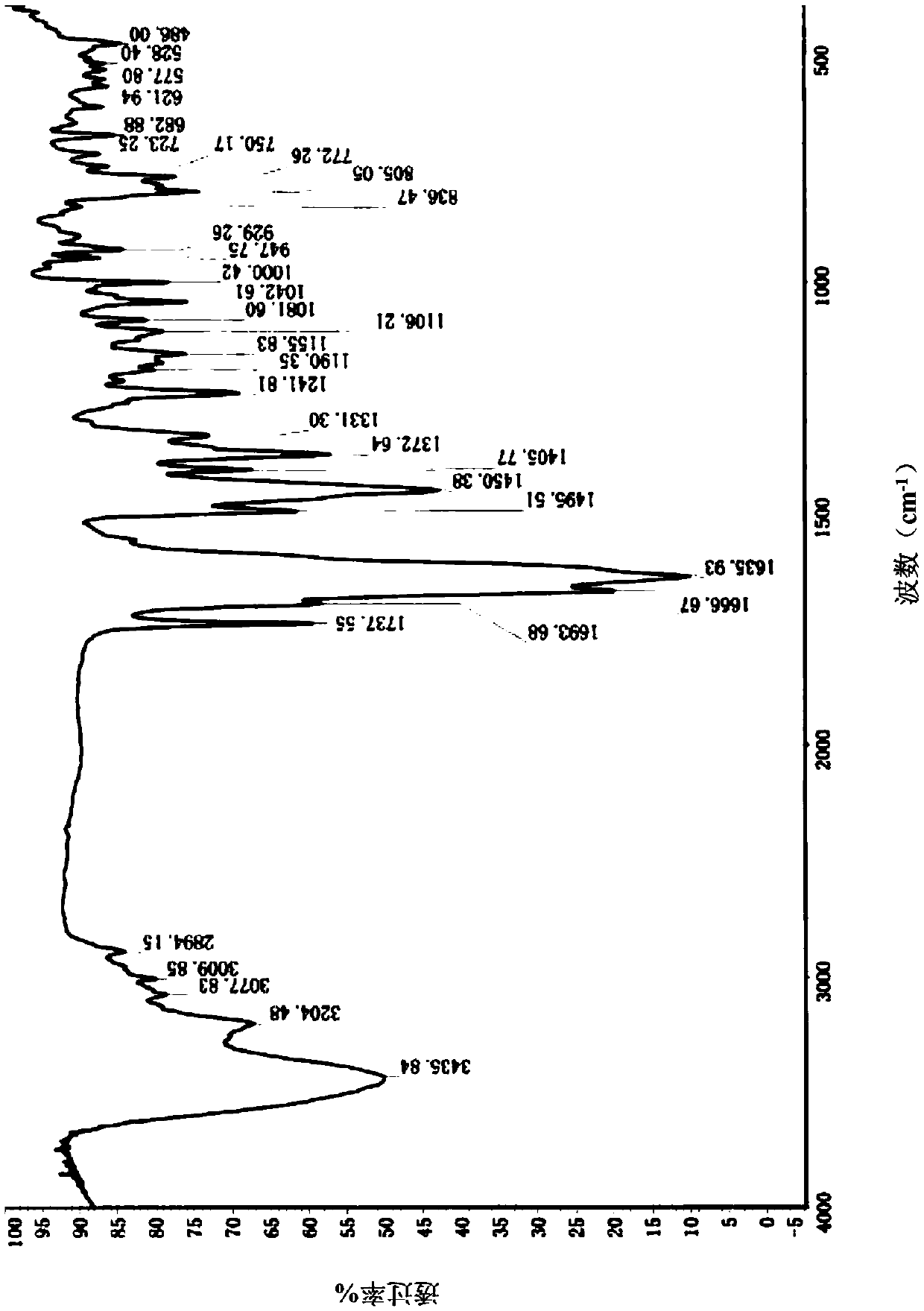

Azoxystrobin acetone solvate and preparation method thereof

The invention relates to an azoxystrobin acetone solvate and a preparation method thereof. Characteristic peaks exist at positions with the following diffraction angles represented by 2theta angles: 7.32+ / -0.20 degrees, 8.42+ / -0.20 degrees, 13.26+ / -0.20 degrees, 14.16+ / -0.20 degrees, 18.04+ / -0.20 degrees, 18.52+ / -0.20 degrees, 18.90+ / -0.20 degrees, 20.40+ / -0.20 degrees, 21.04+ / -0.20 degrees, 22.36+ / -0.20 degrees, 23.96+ / -0.20 degrees, 24.36+ / -0.20 degrees, 26.46+ / -0.20 degrees, 28.4+ / -0.20 degrees, 30.06+ / -0.20 degrees and the like, wherein the characteristic peak at the position with the diffraction angle 2theta of 7.32+ / -0.20 degrees is an initial peak, and the relative strength is 100%. The preparation method is a constant-temperature suspension rotating crystal method, operation is simple, control is easy, reproducibility is good, the problems of difficult filtering and low efficiency in production are solved, and the preparation method is suitable for industrialization.

Owner:TIANJIN UNIV

A kind of hygienic insecticidal suspoemulsion and preparation method thereof

ActiveCN107372578BGood long-term retention activityGood fast knockdown activityBiocideDead animal preservationBiotechnologyChrysanthemum cinerariifolium

The invention relates to hygienic insecticidal suspoemulsion. The suspoemulsion comprises the following components calculated in percentage by weight: 0.1 to 10% of an active component A, 0.5 to 40% of a solvent, 1.0 to 10% of an emulsifying dispersant, 1 to 30% of an active component B, 1.0 to 10% of a wetting dispersant, 0.2 to 5% of an emulsifying stabilizer, 0.05 to 10% of a thickener, 1.0 to 10% of an antifreeze agent, 0.1 to 1.0% of a defoamer, 0.1 to 1.0% of a preservative, 0.1 to 5.0% of an acid-base regulator, and the balance of water; the active component A is knockout pyrethroid; the active component B is fatal pyrethroid; the emulsifying stabilizer is a ultra-high molecular weight copolymer of which the relative molecular weight is 1 to 20 million; in the suspoemulsion, the emulsifying dispersant and the wetting dispersant are optimized, especially the special emulsifying stabilizer is supplemented to solve the stability problem existing in a suspoemulsion system.

Owner:江苏功成生物科技有限公司

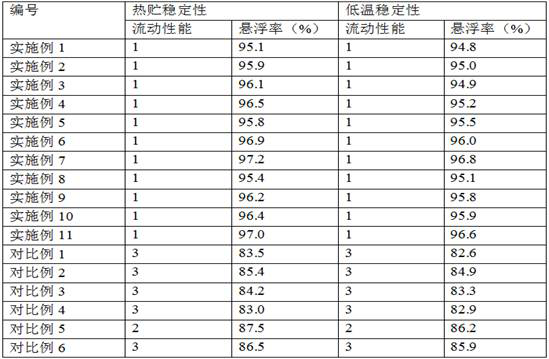

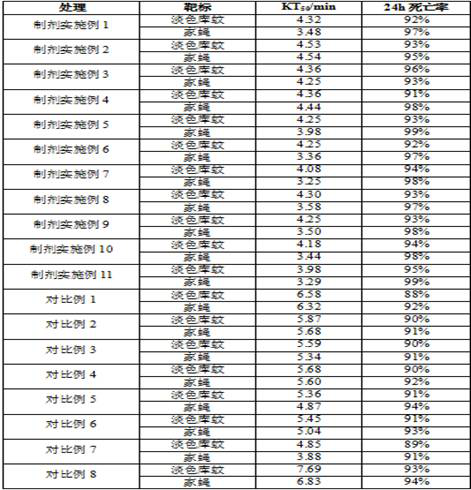

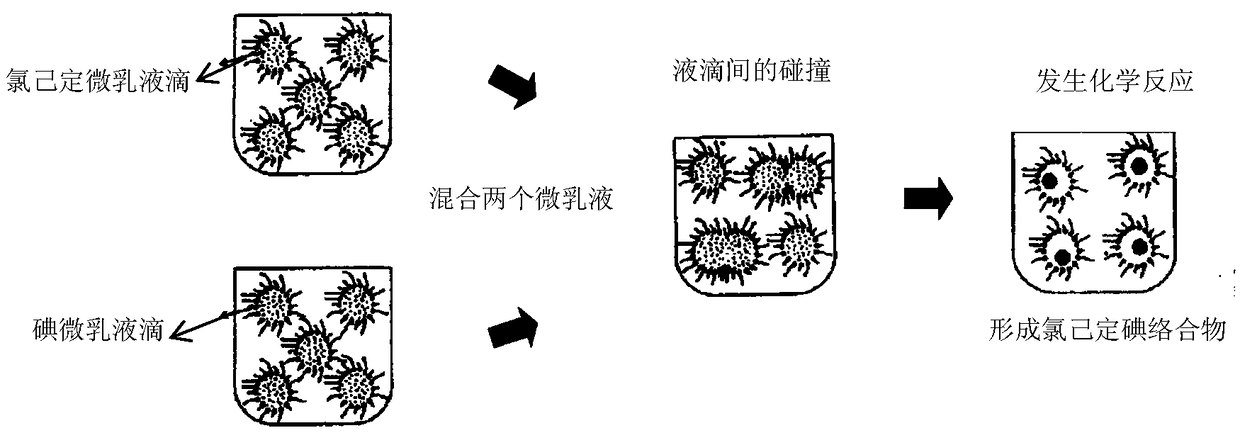

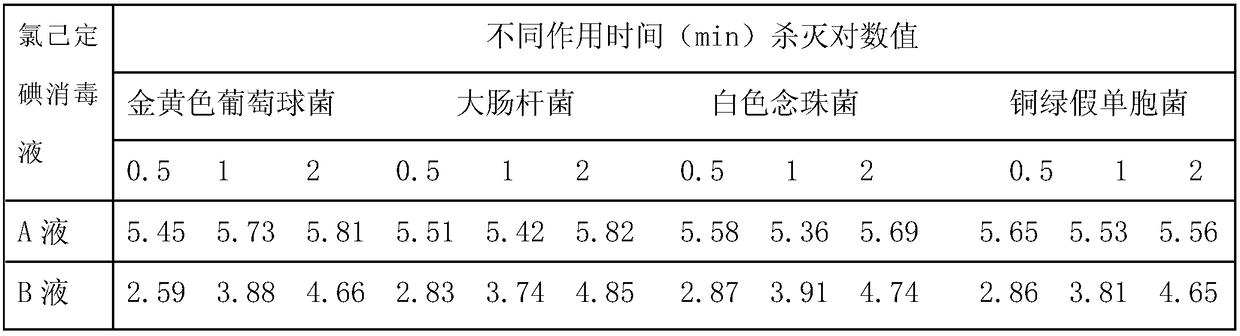

Preparation method of chlorhexidine-iodine nanometer complex

InactiveCN108969534AAchieving joint attackImprove the bactericidal effectAntibacterial agentsOrganic active ingredientsOrganic solventIrritation

The invention relates to a preparation method of a chlorhexidine-iodine nanometer complex. The prepared chlorhexidine-iodine nanometer complex is prepared from the following components in percentage by weight: 5-35 percent of chlorhexidine, 3-30 percent of iodine, 2-18 percent of potassium iodide, 10-30 percent of surfactant, 5-15 percent of cosurfactant, 25-45 percent of organic solvent and 4-30percent of purified water. The chlorhexidine-iodine nanometer complex prepared by utilizing the preparation method is relatively narrow in particle size distribution and liable to control; nanoparticles with uniform particle size can be relatively easily obtained; and by selecting different surface active molecules to perform wrapping and modification on particles, so that the particles are difficult to perform coalescence, and good stability is achieved. Compared with a product by adding an ordinary chlorhexidine-iodine complex in skin and mucosa disinfection hygienic products, by utilizing the chlorhexidine-iodine nanometer complex, a product is good in stability, small in irritation, strong in disinfection effect and safe and convenient to use and has the broad-spectrum antibacterial performance.

Owner:SHANGHAI LIKANG DISINFECTION HIGH TECH

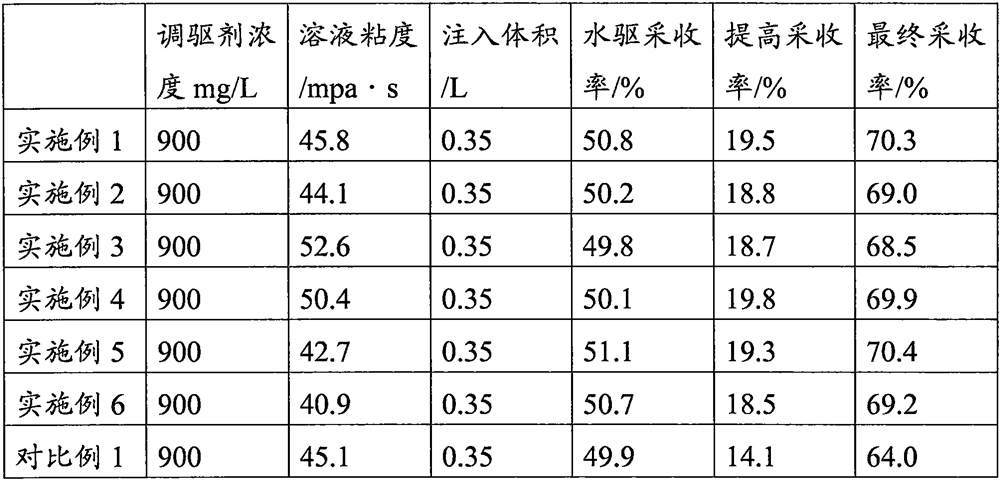

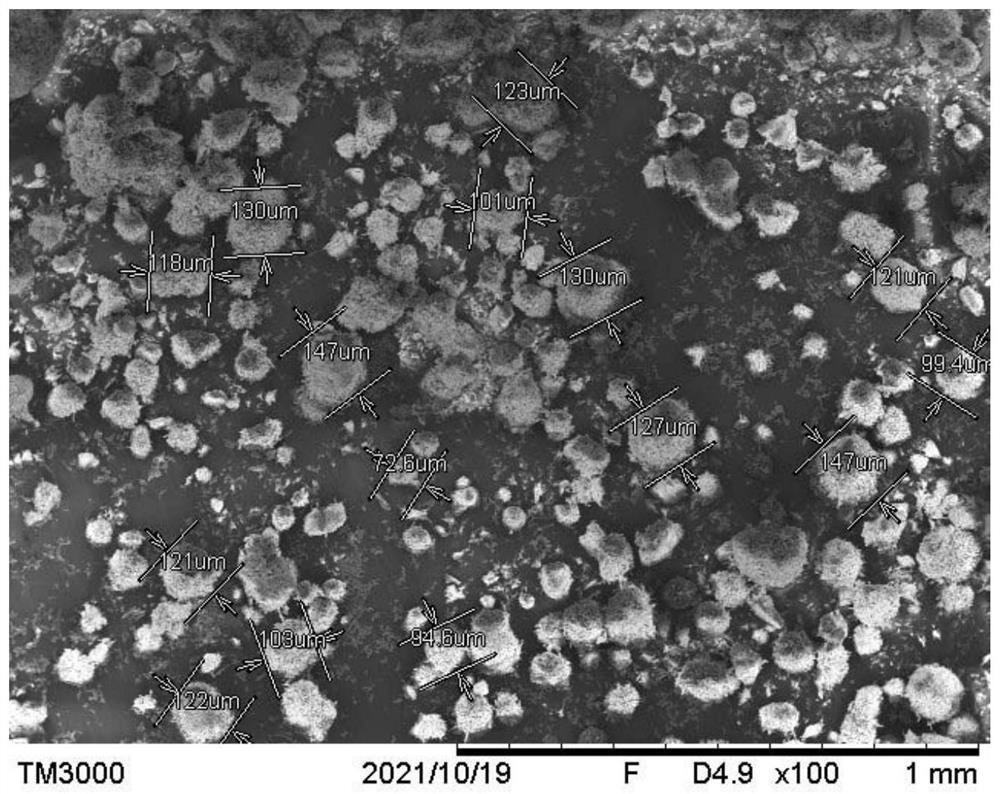

A kind of polymer microsphere regulating and displacing agent and preparation method thereof

ActiveCN110483688BPlay the role of cross-linkingImprove high temperature resistanceDrilling compositionPotassium persulfateMicrosphere

The invention discloses a polymer microsphere adjusting and driving agent, which comprises the following raw materials in parts by weight: 21-25 parts of acrylamide, 5-8 parts of anionic surfactant, 0.5-1.2 parts of crosslinking agent, and 5-8 parts of emulsifier 1.5-2 parts of ammonium persulfate, 0.1-0.5 parts of potassium persulfate, 150-250 parts of oil and 100-280 parts of deionized water; stir the oil and emulsifier evenly to form a continuous oil phase; mix acrylamide, anion surface Active agent, crosslinking agent, and part of ammonium persulfate are dissolved in deionized water to form a water phase; potassium persulfate solution and ammonium persulfate solution are prepared; the water phase is added to the oil phase, ammonium persulfate solution is added at low temperature, and persulfate solution is added at high temperature Potassium solution, constant temperature reaction and natural cooling to room temperature. The invention provides a polymer microsphere control and displacement agent, through the combined reaction of the above-mentioned several materials, it is possible to synthesize polymer gel microspheres with good gel ductility matching its pore throat size, which greatly improves oil recovery .

Owner:东营市惠好科技开发有限责任公司

Preparation method of diesel oil pour point depressant

InactiveCN107619692AGood compatibilityChange surface propertiesLiquid carbonaceous fuelsFuel additivesWaxSynthetic polymer

The invention relates to the technical field of pour point depressants and discloses a preparation method of a diesel oil pour point depressant. A polymer is synthesized from acrylic ester, ethylene,benzoic acid and higher alcohols ester, the carbon chain length of the acrylic ester and the carbon chain length of diesel are similar, the intermiscibility is high, the wrapping is relatively good inthe process of crystallization of the diesel, and the development of a wax crystal is hindered, so that the effect of the diesel pour point is reduced, and moreover, the depressant is adsorbed on theactive center of a crystal nucleus of the wax crystal due to a polar group in the higher alcohols ester, so that the surface characteristic of the wax crystal is changed, the growth of the crystal ishindered or the growth habit of the crystal is changed, the dispersion degree of the wax crystal is improved, the wax crystal does not coalesce easily to form a net, the adhesive attraction between the wax crystals is weakened, the polarity of the depressant is improved by ethylene and the benzoic acid, and the pour point depression effect is further improved.

Owner:常州市协旺纺织品有限公司

Emulsified asphalt

InactiveCN106700932ALow densityLow viscosityAnti-corrosive paintsBituminous coatingsFatty acid methyl esterAsphalt

The invention discloses an emulsified asphalt. The emulsified asphalt comprises the following raw materials by weight: 40-60 parts of asphalt, 5-15 parts of dodecyl dimethyl benzyl ammonium chloride, 5-10 parts of fatty methyl ester ethoxylates, 2-8 parts of sodium carboxy methyl cellulose, 5-10 parts of isobutyl acrylate, and 20-43 parts of water. The emulsified asphalt is used for a protective coating of a metal and forms a compact film, and the shielding property of an emulsified asphalt coating on a metal matrix is improved, so that the corrosion resistance property of the emulsified asphalt coating is further improved. A manufacturing method of the emulsified asphalt is simple and convenient, the used raw materials are easy to get, and the environmental pollution is small.

Owner:FOSHAN RUIJIAN SPORTS EQUIP CO LTD

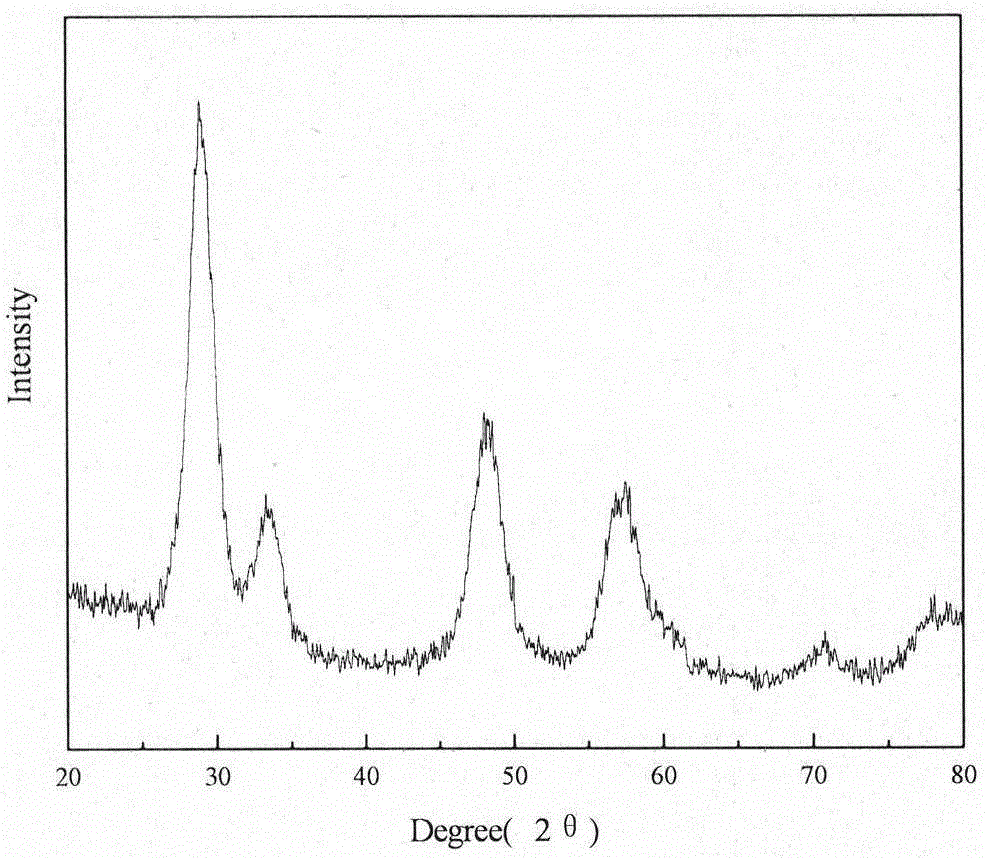

Method for preparing biodiesel by solid superbase catalysis

InactiveCN109022017ASmall sizeHas a cubic shapeBiofuelsLiquid carbonaceous fuelsBiodieselCentrifugation

The invention discloses a method for preparing biodiesel by solid superbase catalysis. A composite oxide solid superbase catalyst used has a small size, has a cubic shape and is not easy to agglomerate at high temperature. The catalyst has simple composition, high catalytic activity and simple preparation. When the catalyst is applied to various catalytic reactions, the catalyst is used in a smallamount and has no corrosion to a reactor, and the catalyst is an environmentally friendly catalyst. After the end of the reaction, the catalyst can be separated by centrifugation. The catalyst can bereused, the yield of the biodiesel is high, and can reach 96%, the preparation time is short, and the biodiesel meets the standard of European EN14214 biodiesel.

Owner:杭州更蓝生物科技有限公司

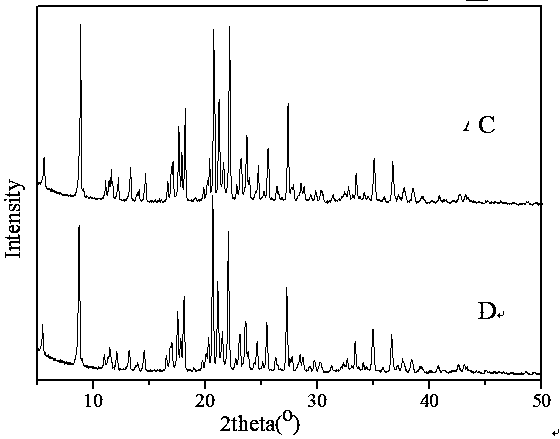

Solvate crystal of PARP inhibitor and preparation method of solvate crystal

ActiveCN110386939AHigh crystallinityHigh purityOrganic active ingredientsNervous disorderEthyl esterMethyl acetate

The invention discloses a solvate crystal of a PARP inhibitor, a preparation method, a pharmaceutical composition and application. The disclosed solvate crystal of a compound in a formula I includes an ethyl acetate solvate crystal A, an ethyl formate solvate crystal B, a methyl acetate solvate crystal C and an n-propyl formate solvate crystal D.

Owner:SHANGHAI DE NOVO PHARMA

Peanut sprout-containing vegetable protein drink and processing technique thereof

InactiveCN109953126AStrong health functionIncrease diversityMilk substitutesBiotechnologyFood additive

The invention discloses a peanut sprout-containing vegetable protein drink and a processing method thereof, which belongs to the field of food processing. The vegetable protein drink is composed of, by weight, the following components: 20-30 parts of peanut sprout pulp, 5-10 parts of peanut rice pulp, 1-2 parts of winter jujube pulp, 1-2 parts of an apple extract, 0.01-0.03 part of honey, 0.001-0.004 part of a food additive, and 30-50 parts of purified water; The protein drink tastes good, is rich in nutrient, has a health care function, and has a function of lowering blood fat for long-term drinking.

Owner:江西秀芽农业有限公司

Diesel fuel pour-point depressant dispersant

ActiveCN101709233BIncreased sensitivityImprove pour point depressing effectLiquid carbonaceous fuelsFuel additivesPolyethylene glycolEther

The invention discloses a diesel fuel pour-point depressant dispersant and a preparation method thereof. The dispersant comprises the following components by weight percentage: 0-20% of Tween, 0-20% of polyethylene glycol, 0-10% of vinyl alcohol butyl ether, 0-10% of polar nitrogenous compounds and 50-80% of Span-80. The raw materials are weighed and mixed according to the weight percentage, and then the materials are stirred in a stirring tank with the speed of 100rpm for 30 min at the temperature of 50 DEG C, and the dispersant is prepared. In the invention, a new dispersant mixture is prepared by combining and mixing various kinds of dispersants uniformly, and then is used with the pour-point depressant according to a certain proportion, thereby improving the sensitivity of the pour-point depressant and the effect of pour point depression.

Owner:SHANGHAI INST OF TECH

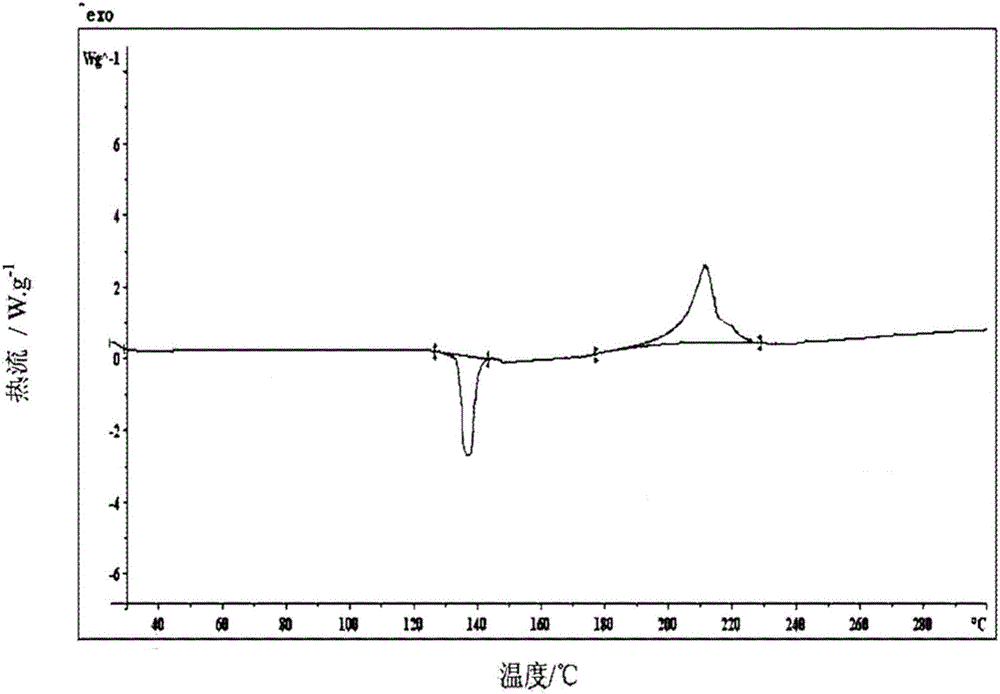

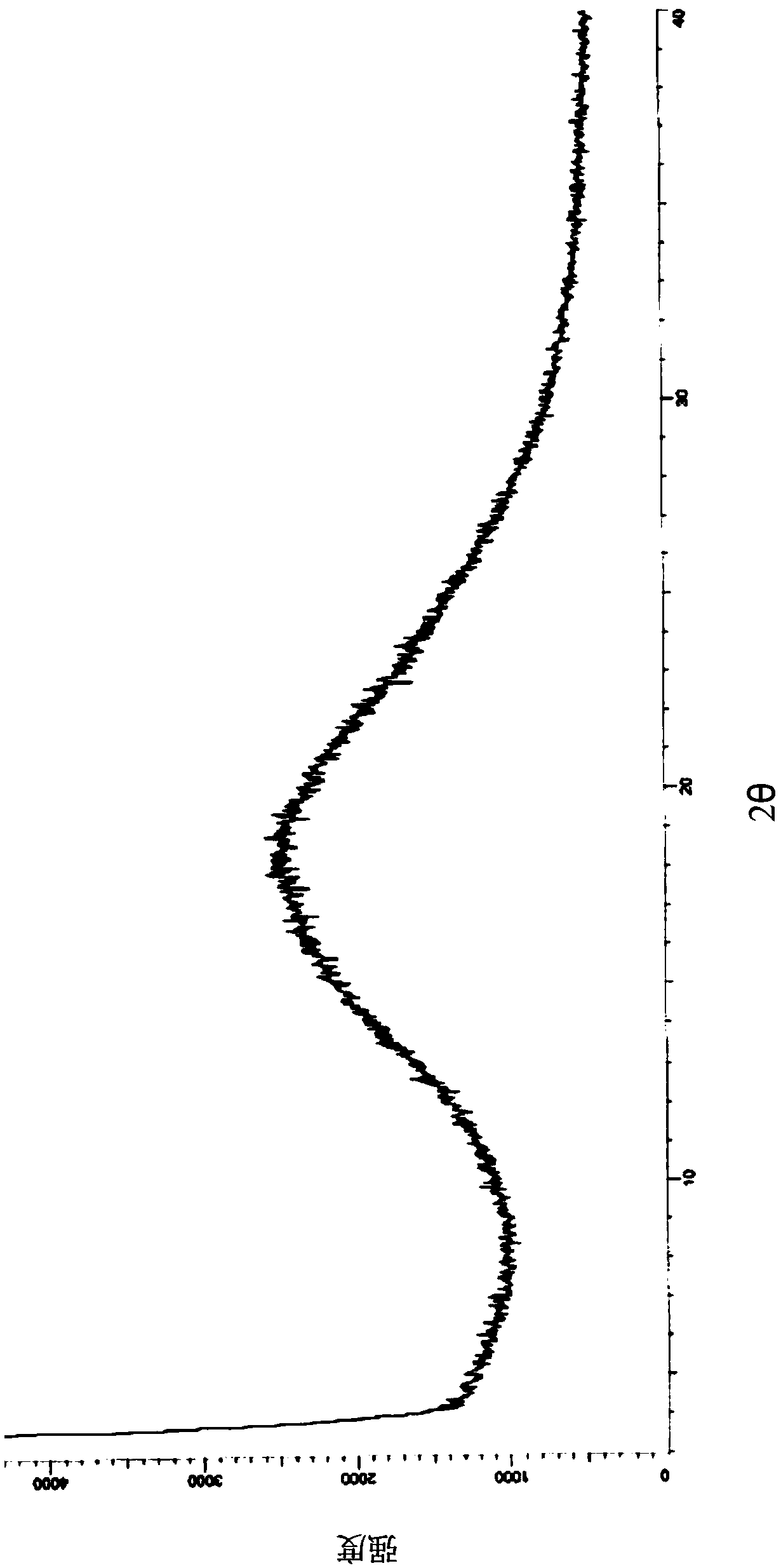

A kind of omeprazole sodium 1,2-propylene glycol solvate and preparation method

ActiveCN104844572BStrong bondHigh crystallinityOrganic chemistryOmeprazole SodiumEsomeprazole Sodium

The present invention discloses an esomeprazole sodium 1,2-propylene glycol solvate and a preparation process thereof, wherein X-ray powder diffraction spectrogram has characteristic diffraction peaks when a diffraction angle 2theta is 5.84+ / -0.1, 10.88+ / -0.1, 11.78+ / -0.1, 15.58+ / -0.1, 20.36+ / -0.1, 20.98+ / -0.1,22.54+ / -0.1, 22.90+ / -0.1, 23.98+ / -0.1, 24.42+ / -0.1, 24.68+ / -0.1, 25.32+ / -0.1, 26.36+ / -0.1, 27.82+ / -0.1, 29.76+ / -0.1, 31.74+ / -0.1, and 32.40+ / -0.1. The starting material esomeprazole sodium is added to the 1,2-propylene glycol, the mixture is stirred at a temperature of 10 to 60 DEG C for 2 to 9 hours, and through filtering and drying, the esomeprazole sodium 1,2-propylene glycol solvate is obtained. The preparation process according to the present invention is simple, achieves a high yield, and obtains safe and nontoxic solvent. The obtained product esomeprazole sodium 1,2-propylene glycol solvate has a greater crystalline granularity, fails to be aggregated simply, and achieves a good stability.

Owner:TIANJIN UNIV +1

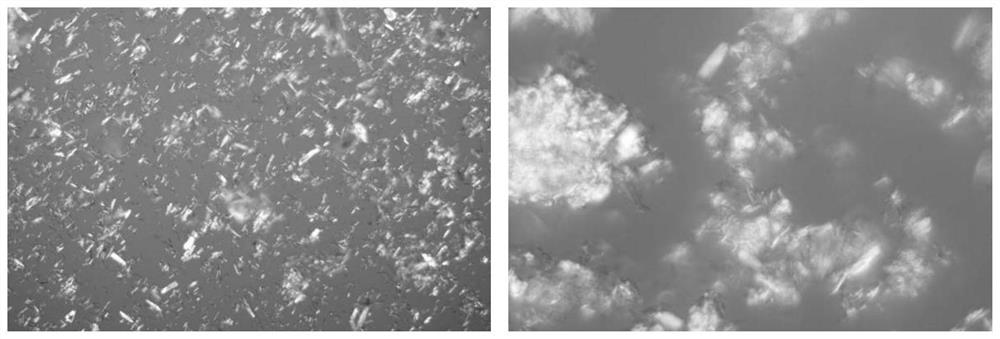

Preparation method and application of spherical crystal of disodium adenosine triphosphate

PendingCN114560895AUniform particle sizeHigh purityOrganic active ingredientsNervous disorderCrystallographyAdenosine

The invention provides a preparation method and application of a spherical crystal of disodium adenosine triphosphate. Specifically, the invention provides a spherical crystal of a compound as shown in a formula I. The crystal is uniform in particle size, high in purity, good in fluidity, not prone to coalescence, high in bulk density and convenient to separate and dry.

Owner:苏州赜文医药科技有限公司

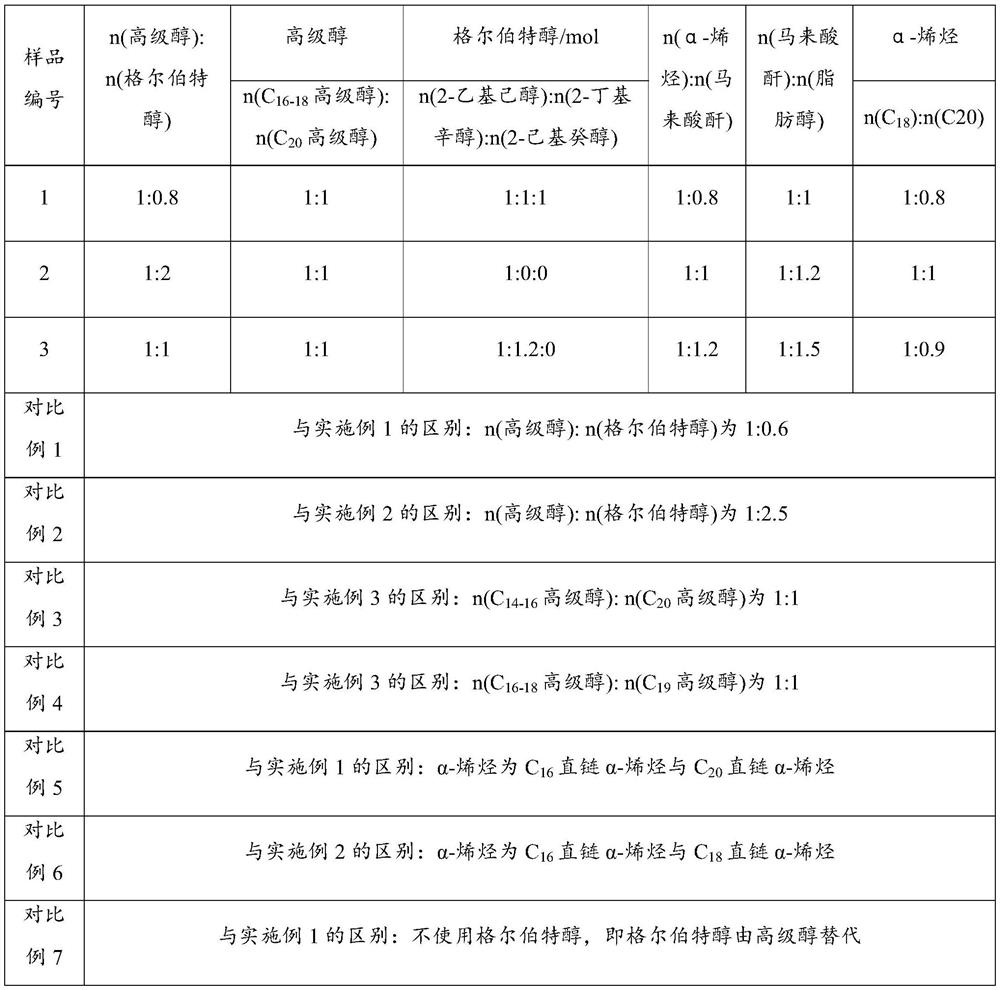

A kind of preparation method of high waxy crude oil pour point depressant

ActiveCN111019033BImprove pour point depressing effectImprove molecular structurePipeline systemsChemical reactionFatty alcohol

The present application proposes a method for preparing a pour point depressant for high waxy crude oil, which includes using α-olefin and maleic anhydride to carry out a free radical copolymerization reaction to obtain a pour point depressant intermediate, and then esterifying the pour point depressant intermediate with aliphatic alcohol. The process of obtaining crude pour point depressant products through chemical reaction, and the fatty alcohol is a mixed alcohol of higher alcohol and Guerbet alcohol. The present application utilizes α-olefin and maleic anhydride to undergo a copolymerization reaction to form a copolymer, and at the same time, maleic anhydride itself has an acid anhydride, which can react with aliphatic alcohol to be esterified to obtain a pour point depressant, which has a good pour point depressant effect. In this application, a large branched Guerbet alcohol is introduced on the basis of the copolymer to improve the molecular structure of the pour point depressant, so that the content of the product is increased to 80%, the freezing point is less than or equal to 15°C, and the safety of the product due to low concentration transportation is reduced. risk and save on shipping costs.

Owner:DESHI ENERGY TECH GRP CO LTD +1

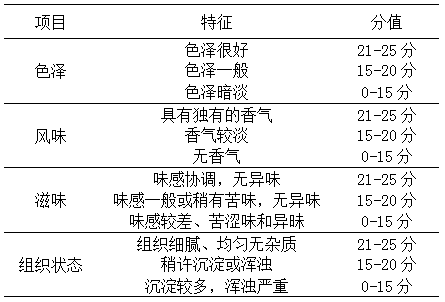

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com