Preparation method of prothioconazole I-type crystal form

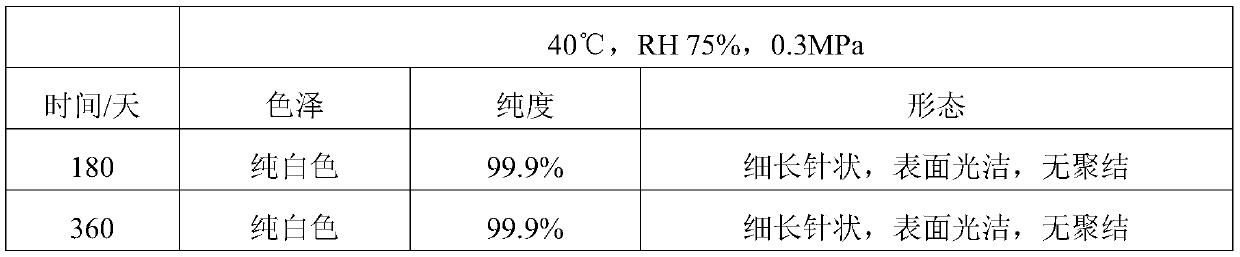

A technology of prothioconazole and crystal form, which is applied in the field of preparation of prothioconazole type I crystal form, can solve the problems of low product yield, poor stability, cumbersome operation, etc., and achieve high purity and crystal form Regular and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of prothioconazole type I crystal form, the specific steps are as follows:

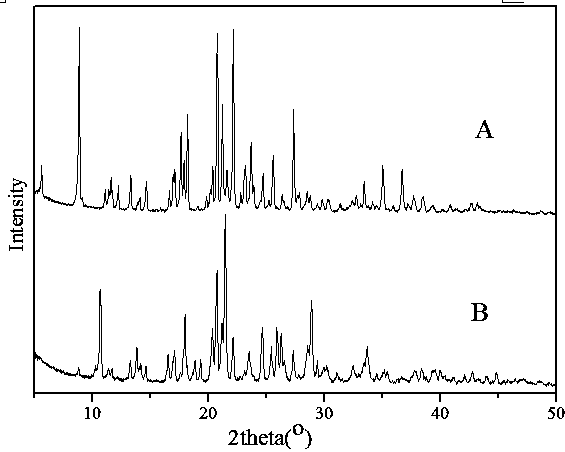

[0028] Put 0.344 g of prothioconazole crude drug in a round bottom flask, add 3ml of toluene into the round bottom flask, heat and stir in a water bath at 50°C for 3 hours, filter while hot, and let the filtrate stand for 3 days after cooling to room temperature to collect the precipitated solid The phase was subjected to negative pressure suction filtration to obtain 0.325 g of type I prothioconazole crystals, the content detected by HPLC analysis: 99.9%, and the melting range: 140.1-140.4°C. The main particle size is 180μm, the bulk density is 0.58g / mL, and the angle of repose is 30°. Use D8 X-ray diffractometer of German BRUKER company to measure, the test conditions are Cu-Kα target tube voltage 40kV, tube current 10mA, scan speed 2° / min, the PXRD diffraction pattern of the product can be found in figure 1 , based on the characteristic reflection, it was confirmed to b...

Embodiment 2

[0030] A preparation method of prothioconazole type I crystal form, the specific steps are as follows:

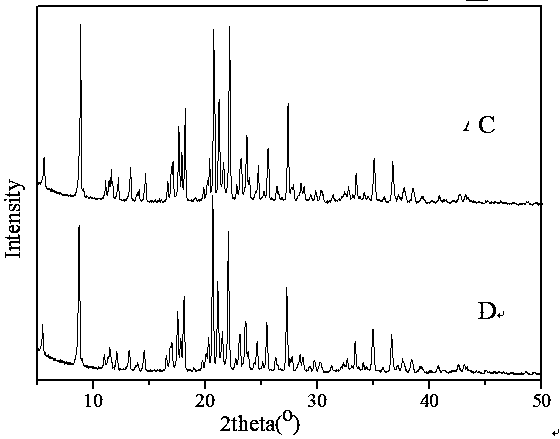

[0031] Put 0.344 g of a mixture of prothioconazole type I crystals and type II crystals (mass ratio: 2:8) in a round bottom flask, add 3 ml of toluene into the round bottom flask, heat and stir in a water bath at 60°C for 2 hours, and filter while hot , the filtrate was cooled to room temperature and then left to stand for 4 days to collect the precipitated solid phase, and filtered under negative pressure to obtain 0.338 g of type I prothioconazole crystals, the content of which was detected by HPLC analysis: 99.9%, and the melting range: 140.1-140.3°C. The main particle size is 180μm, the bulk density is 0.58g / mL, and the angle of repose is 30°. The spectrum of the product was obtained after PXRD detection, and based on the characteristic reflection, it was confirmed to be the crystal form of prothioconazole I.

Embodiment 3

[0033] A preparation method of prothioconazole type I crystal form, the specific steps are as follows:

[0034]Put 0.344 g of amorphous prothioconazole in a round-bottomed flask, add 3 ml of toluene into the round-bottomed flask, heat and stir in a water bath at 80°C for 2 hours, filter while hot, and let the filtrate stand for 4 days after cooling to room temperature to collect the precipitated The solid phase was filtered under negative pressure to obtain 0.338 g of type I prothioconazole crystals, the content detected by HPLC analysis: 99.9%, and the melting range: 140.0-140.5°C. The main particle size is 180μm, the bulk density is 0.58g / mL, and the angle of repose is 30°. The spectrum of the product was obtained after PXRD detection, and based on the characteristic reflection, it was confirmed to be the crystal form of prothioconazole I.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com