Preparation method of diesel oil pour point depressant

A diesel pour point depressant and pour point depressant technology, which is used in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of high wax content and can not provide polywax crystal dispersion, etc., to reduce adhesion and improve. Anticoagulant effect, effect of altering growth habit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

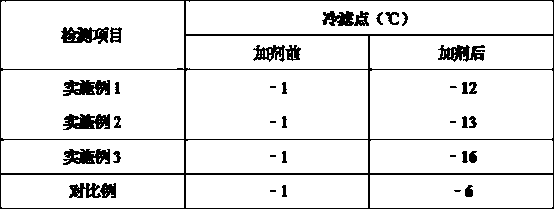

Examples

Embodiment 1

[0025] The choice of water carrier: chloroform.

[0026] Catalyst of choice: ethylenediaminetetraacetic acid.

[0027] Choice of surfactant: sodium dizincyl sulfosuccinate.

[0028] (1) In parts by weight, take 50 parts of toluene, 30 parts of acrylate, 20 parts of benzoic acid, 25 parts of higher alcohol ester, 1 part of water-carrying agent, 2 parts of catalyst, and 1 part of surfactant;

[0029] (2) Put toluene and acrylate into the reactor, feed ethylene, discharge the gas in the reactor, add water-carrying agent and catalyst, raise the temperature to 50°C, then add benzoic acid and higher alcohol ester, and raise the temperature to 110°C for reaction;

[0030] (3) After 5 hours of reaction, end the reaction, vent ethylene, cool to room temperature, collect the reaction mixture, distill the reaction mixture, recover toluene, and collect the distillation residue;

[0031] (4) Filter the distillation residue, collect the filtrate, mix the filtrate with a surfactant, and c...

Embodiment 2

[0033] The choice of water carrier: chloroform.

[0034] Catalyst of choice: periodic acid.

[0035] Surfactant of choice: sodium dodecylbenzenesulfonate.

[0036] (1) In parts by weight, take 55 parts of toluene, 33 parts of acrylate, 23 parts of benzoic acid, 27 parts of higher alcohol ester, 3 parts of water-carrying agent, 2 parts of catalyst, and 2 parts of surfactant;

[0037] (2) Put toluene and acrylate into the reactor, feed ethylene, discharge the gas in the reactor, add water-carrying agent and catalyst, raise the temperature to 55°C, then add benzoic acid and higher alcohol ester, and raise the temperature to 115°C for reaction;

[0038] (3) After 6 hours of reaction, end the reaction, vent ethylene, cool to room temperature, collect the reaction mixture, distill the reaction mixture, recover toluene, and collect the distillation residue;

[0039] (4) Filter the distillation residue, collect the filtrate, mix the filtrate with a surfactant, and collect the mixtu...

Embodiment 3

[0041] The choice of water carrier: carbon tetrachloride.

[0042] Catalyst of choice: periodic acid.

[0043] Surfactant of choice: Sodium dodecylbenzenesulfonate.

[0044] (1) In parts by weight, take 60 parts of toluene, 35 parts of acrylate, 25 parts of benzoic acid, 30 parts of higher alcohol ester, 4 parts of water-carrying agent, 3 parts of catalyst, and 2 parts of surfactant;

[0045] (2) Put toluene and acrylate into the reactor, feed ethylene, discharge the gas in the reactor, add water-carrying agent and catalyst, raise the temperature to 60°C, then add benzoic acid and higher alcohol ester, and raise the temperature to 120°C for reaction;

[0046] (3) After 7 hours of reaction, end the reaction, vent ethylene, cool to room temperature, collect the reaction mixture, distill the reaction mixture, recover toluene, and collect the distillation residue;

[0047] (4) Filter the distillation residue, collect the filtrate, mix the filtrate with a surfactant, and collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com