Preparation method of superfine manganese oxide

A technology of manganese oxide and manganese salt, which is applied in the field of preparation of ultra-fine manganese oxide, can solve the problems of powder particle size not reaching the nanometer level, strong oxidation and corrosion, etc. The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh manganese nitrate Mn(NO 3 ) 2 (concentration 50%, analytical pure AR, molecular weight 178.95) solution 35.8 grams, (being Mn(NO 3 ) 2 0.1mol), after heating to 40°C in a water bath, 12.9 grams of citric acid (C 6 h 8 o 7 , analytically pure, molecular weight 192.14) particles (0.067mol), stirred to dissolve in the above Mn(NO 3 ) 2 solution, denoted as A1.

[0041] Raise the temperature of the water bath to 50° C., and place A1 there for 6 hours to form B1.

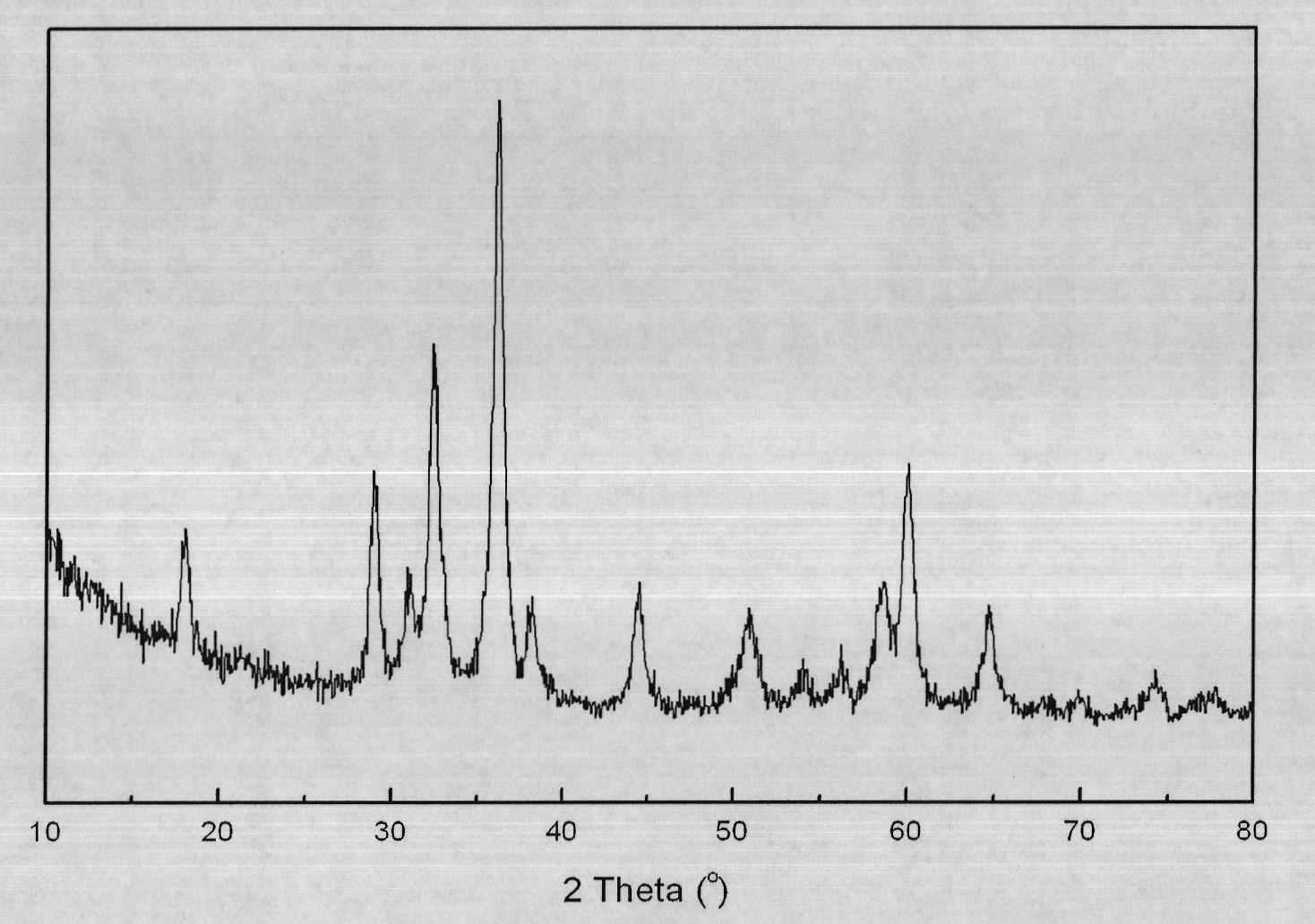

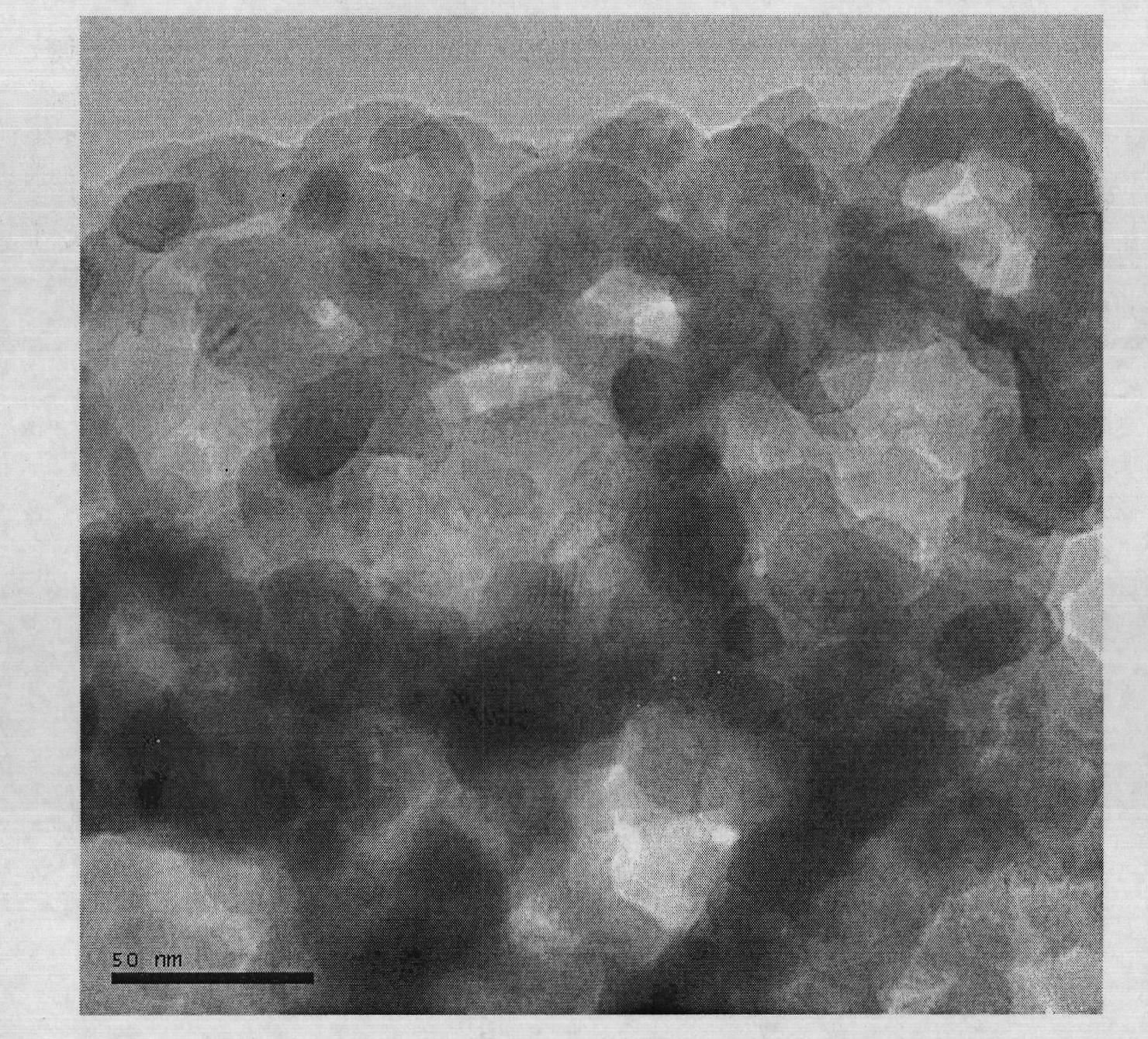

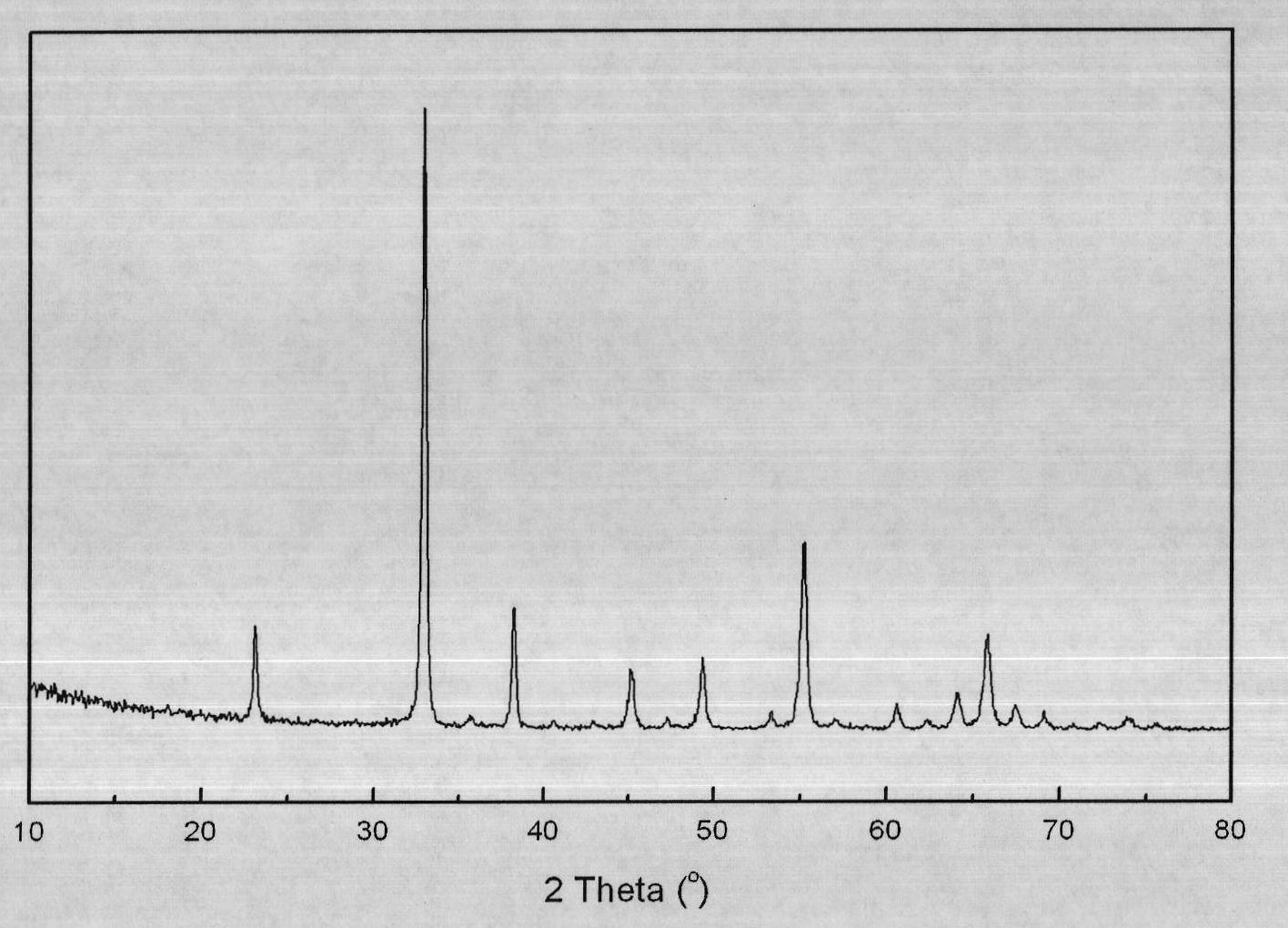

[0042] Put B1 into an oven, bake at 110°C for 4 hours, put it into a muffle furnace, and bake at 300°C for 4 hours to form C1. Carry out XRD and TEM analysis and test of C1, and the results of the obtained crystal form and particle size are shown in the attached figure 1 and figure 2 .

Embodiment 2

[0044] Weigh manganese acetate (Mn(CH 3 COO) 2 4H 2 O, AR, molecular weight 245.10) 24.5 grams (0.1mol), make it be dissolved in 25 grams of deionized water, form the manganese acetate solution of 35%, after being heated to 40 ℃ in water bath, add 19.2 grams of citric acid particles wherein ( 0.1mol), stirred to dissolve in manganese acetate solution, denoted as A2.

[0045] Raise the temperature of the water bath to 50° C., and place A2 there for 8 hours to form B2.

[0046] Put B2 into an oven, bake at 100°C for 4 hours, put it into a muffle furnace, and bake at 300°C for 4 hours to form C2. The results of XRD and TEM analysis of C2 are shown in Table 1.

Embodiment 3

[0048] Weigh Mn(NO 3 ) 2 (50%, AR) solution 35.8 grams (0.1mol), after heating to 40 ℃ in water bath, add 15 grams (0.1mol) tartaric acid (C 4 h 6 o 6 , AR, molecular weight 150.09), stirred to dissolve in Mn(NO 3 ) 2 solution, denoted as A3.

[0049]Raise the temperature of the water bath to 50° C., and place A3 there for 5 hours to form B3.

[0050] Put B3 into an oven, bake at 110°C for 4 hours, put it into a muffle furnace, and bake at 350°C for 4 hours to form C3. C3 was analyzed and tested by XRD and TEM, and the results of crystal form and particle size are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com