A kind of preparation method of high waxy crude oil pour point depressant

A crude oil pour point depressant and pour point depressant technology, which is applied in mechanical equipment, pipeline systems, gas/liquid distribution and storage, etc. The effect of controlling the degree of reaction polymerization, reducing safety risks, and good pour point reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

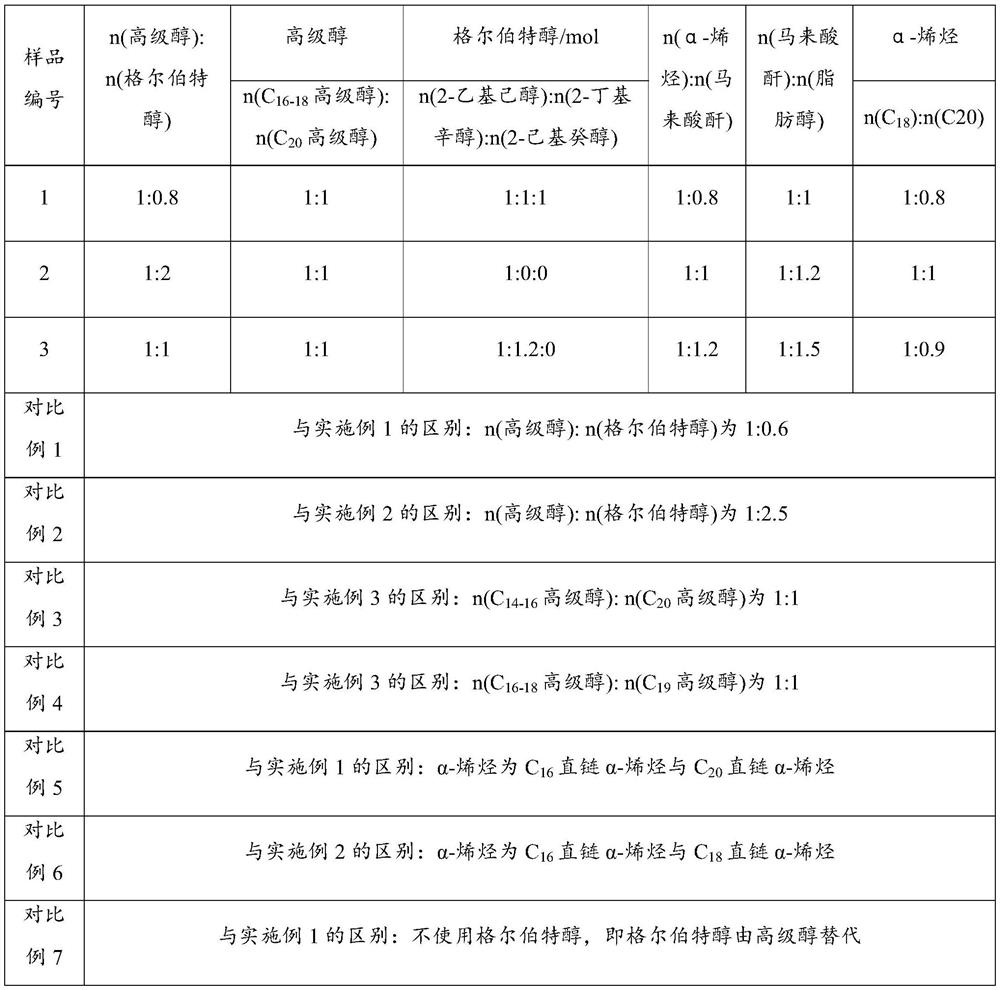

Examples

Embodiment 1

[0025] Embodiment 1: a kind of preparation method of high waxy crude oil pour point depressant:

[0026] (1) Preparation method of pour point depressant intermediate

[0027] In a dry and clean reaction kettle, the molten reactant α-olefin and organic solvent xylene are put in by a vacuum pump, and the temperature is raised to about 50°C to 75°C with stirring. After 110-130 min of the reaction for keeping the temperature of the agent, the temperature is lowered to obtain the intermediate of pour point depressant;

[0028] Wherein, the initiator is added in four times in turn. In terms of parts, the first addition is 10-15 parts, and the temperature is kept at 125 ° C for 25-35min; the second addition is 20-30 parts, and the heat is kept for 25-35min; The third addition is 20-30 parts, and the temperature is kept for 85-95 minutes; the fourth addition is 30-40 parts, and the temperature is kept for 85-95 minutes.

[0029] (2) Preparation method of finished product of crude po...

Embodiment 2

[0036] Example 2: Characterization

[0037] The high waxy crude oil used in this example is used as the experimental oil, the freezing point of the experimental oil is 33 ° C, the wax content is 23%, the colloidal asphaltene content is 10-15%, and the viscosity is 800-1200mPa. s, the pour point of crude oil pour point depressant is tested according to the standard of GB / T510-1983.

[0038] In this example, the viscosity is the viscosity value of the crude pour point depressant at 60°C.

[0039] The flash point is tested according to GB / T 261.

[0040]Table 2 Performance test results of crude oil pour point depressant

[0041] Sample serial number Freezing point / ℃ Decrease / ℃ Flash point / ℃ Viscosity mPa.s Solid content / % Molecular weight Mw 1 13 10 28 260 89 6000 2 8 15 25 200 85 5120 3 3 20 35 150 90 7500 Comparative Example 1 16 7 26 310 53 8500 Comparative Example 2 18 5 23 280 57 8126 Comparative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com