Preparation method and application of spherical crystal of disodium adenosine triphosphate

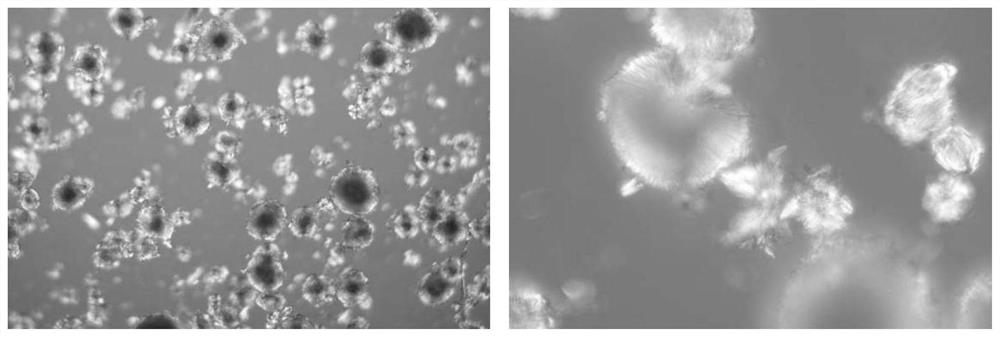

A technology of disodium adenosine triphosphate and spherical crystals, applied in the field of medicine, can solve the problems of difficult suction filtration and drying, thin crystals, loose aggregates and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] Preparation method of adenosine triphosphate disodium spherical crystal

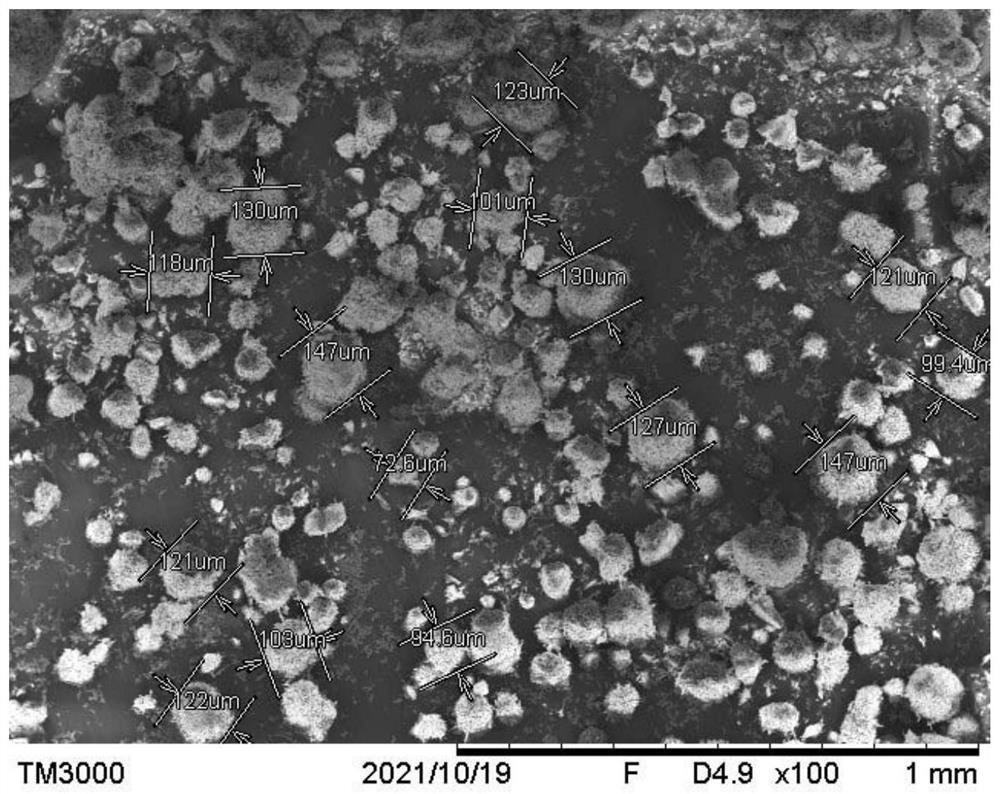

[0069] In order to overcome the defects in the prior art, the present invention provides a novel method for preparing spherical adenosine triphosphate disodium crystals. The spherical adenosine triphosphate disodium crystals prepared by the method have low bulk density, good fluidity, high purity and uniform particle size.

[0070] Typically, the present invention provides a method for preparing spherical crystals of adenosine triphosphate disodium shown in formula (I), comprising the steps of:

[0071] (1) providing disodium adenosine triphosphate raw material in water, stirring and preparing disodium adenosine triphosphate aqueous solution, wherein the disodium adenosine triphosphate aqueous solution is a saturated or supersaturated aqueous solution with a mass fraction of 5-42%;

[0072] (2) crystallization, described crystallization step is carried out by (Ia)-(Ib):

[0073] (Ia) Adjust the t...

Embodiment 1

[0121] At room temperature, add 12.6 g of adenosine triphosphate disodium raw material into 56.5 mL of water to prepare about 20% adenosine triphosphate disodium aqueous solution. Stir at 250rpm, add 138mL of absolute ethanol dropwise to the aqueous solution at 45°C at a rate of about 1.3mL / min, when it reaches 12mL, fine crystals precipitate out of the solution, the solution is slightly cloudy, and the dropwise addition is suspended. The temperature of the solution was lowered to 30°C, and the dropwise addition was continued after keeping the temperature for 10 minutes.

[0122] After the dropwise addition, keep warm for 1h. Subsequently, the temperature was lowered to 20°C at a rate of 10°C / h, and then kept for 30 minutes, and then the material was collected.

[0123] After vacuum filtration, the filter cake was washed with about 145 mL of absolute ethanol, and the filtration speed was fast to obtain 17.8 g of wet product. After vacuum drying at 35°C, 12.3 g of dry product...

Embodiment 2

[0126] At room temperature, add 12.6 g of adenosine triphosphate disodium raw material into 113 mL of water to prepare about 10% adenosine triphosphate disodium aqueous solution. Stir at 250rpm, add 276mL of absolute ethanol dropwise to the aqueous solution at 45°C at a rate of about 1.3mL / min. When the solution reaches about 27mL, fine crystals will precipitate out of the solution, and the solution will be slightly cloudy, so stop the dropwise addition. The temperature of the solution was lowered to 30°C, and the dropwise addition was continued after keeping the temperature for 10 minutes.

[0127] After the dropwise addition, keep warm for 1h. Subsequently, the temperature was lowered to 20°C at a rate of 10°C / h, and then kept for 30 minutes, and then the material was collected.

[0128] After vacuum filtration, the filter cake was washed with about 142 mL of absolute ethanol, and the filtration speed was fast to obtain 20.7 g of wet product. After vacuum drying at 35°C, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com