Diesel fuel pour-point depressant dispersant

A diesel oil point depressant and dispersant technology, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problem that the effect of the dispersant is not particularly significant, and achieve the improvement of the point depressant effect, the effect is obvious, and the preparation method is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of described diesel oil pour point depressant dispersant comprises the following steps:

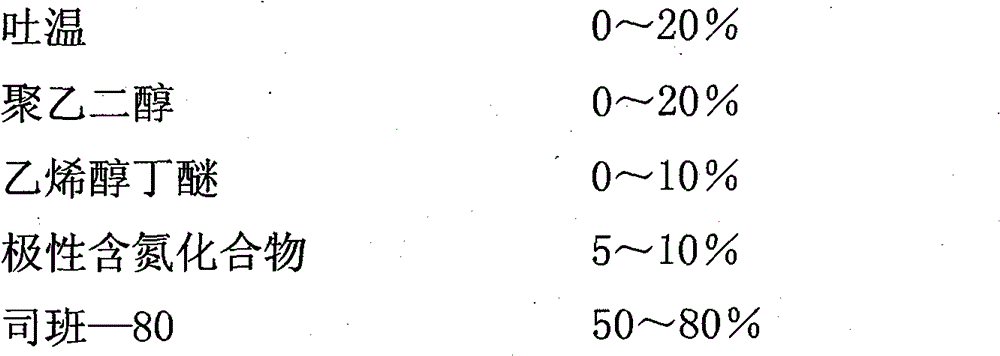

[0030] A. Weigh and mix the raw materials according to the following weight percentages:

[0031] Tween 0~20%

[0032] Polyethylene glycol 0-20%

[0033] Vinyl butyl ether 0~10%

[0034] Polar nitrogen-containing compounds 0~10%

[0035] Siban-80 50~80%

[0036] Wherein, the polyethylene glycol molecular weight is 200-800, and the polar nitrogen-containing compound is selected from one of polyisobutylene diimide, triethylenetetramine, triethanolamine, and triethylamine;

[0037] B. Stir the above-mentioned raw materials in a stirred tank at a rotation speed of 100 rpm and a temperature of 50°C for 30 minutes to obtain the dispersant.

Embodiment 1

[0039] Dispersant for diesel pour point depressant consists of the following components by weight:

[0040] Tween 5%

[0041] Polyethylene Glycol 5%

[0042] Vinyl Butyl Ether 5%

[0043] Polyisobutylene diimide 10%

[0044] Span - 80 75%

[0045] Mix the dispersant prepared above with ethylene-vinyl acetate at a ratio of 1:4 and add them to Hejiawan 0 # Diesel, Jinshan 0 # Diesel, Fuyang 0 # The cold filter point of diesel oil is reduced by -15°C, -13°C, -11°C respectively, the effect is obvious and the method is simple.

Embodiment 2

[0047] Dispersant for diesel pour point depressant consists of the following components by weight:

[0048] Tween 10%

[0049] Polyethylene Glycol 10%

[0050] Vinyl Butyl Ether 5%

[0051] Polyisobutylene diimide 5%

[0052] Span - 80 70%

[0053] Mix the dispersant prepared above with ethylene-vinyl acetate at a ratio of 1:4 and add them to Hejiawan 0 # Diesel, Jinshan 0 # Diesel, Fuyang 0 # The cold filter point of diesel oil is reduced by -10°C, -10°C and -8°C respectively, the effect is obvious and the method is simple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com