Method for synthesis of nano cerium zirconium solid solution through microemulsion method

A cerium zirconium solid solution, microemulsion technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, etc. It can solve the problems of long aging time, etc., to achieve the effect of short aging time, simple post-processing and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First prepare a mixed solution of cetyltrimethylammonium bromide (CTAB), n-butanol, and cyclohexane with a molar ratio of 1:8:34, and divide it into two parts for later use. A mixture of cerium nitrate and zirconium oxynitrate (molar ratio Ce:Zr=67:33) is added to one part to form a microemulsion, and the other part is added to ammonia water to form a microemulsion. The two microemulsions were mixed under vigorous stirring and aged for 12 h at room temperature. After filtering and fully washing with deionized water, the precipitate was washed with absolute ethanol. Then dry it in a drying oven at 110°C for 2 hours, and then bake it at 500°C for 2 hours.

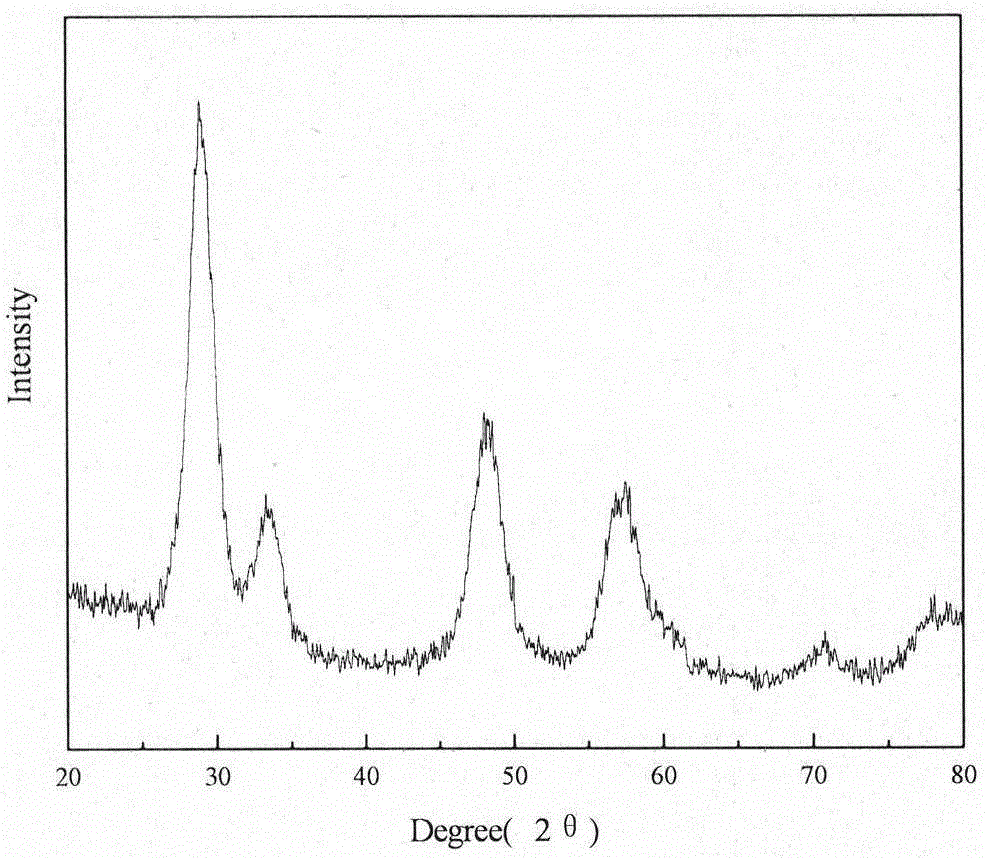

[0024] The X-ray diffraction pattern of cerium-zirconium solid solution is shown in figure 1 . The X-ray (XRD) analysis of the sample adopts the BrukerAXDD8advance type X-ray diffractometer produced by Germany Bruker Company to measure, using CuK α X-ray, voltage 40kV, current 40mA, scanning range 2θ=20°~80°. From...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com