A kind of polymer microsphere regulating and displacing agent and preparation method thereof

A technology for controlling displacement agent and polymer, which is applied in the field of polymer microsphere controlling displacement agent and its preparation. Residual resistance coefficient, the effect of improving high temperature resistance and shear resistance, and improving oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

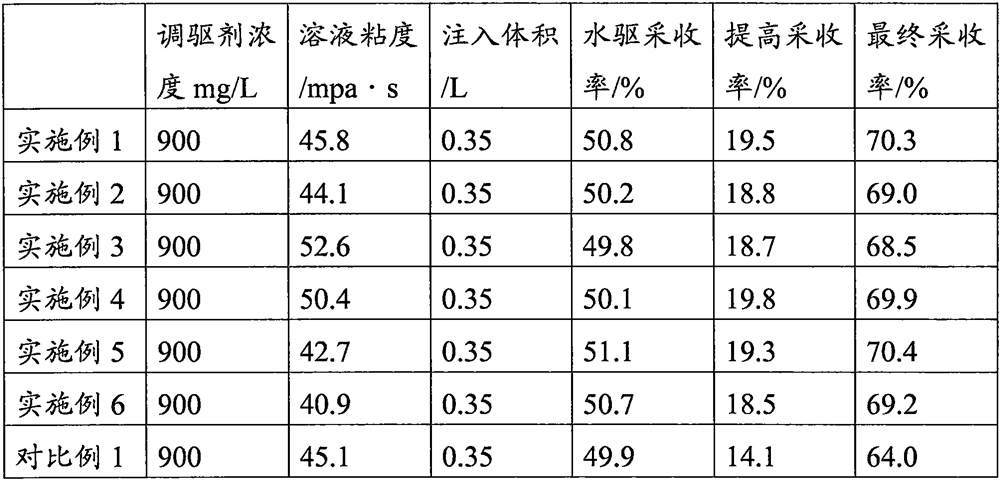

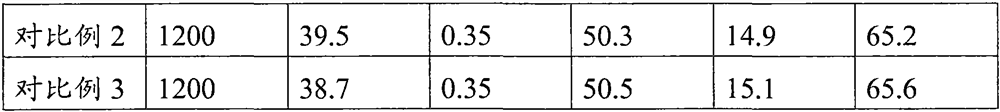

Examples

Embodiment 1

[0029] A polymer microsphere regulating and displacing agent, it is composed of acrylamide 21g, 4-vinylbenzenesulfonate 5g, N, N-methylenebisacrylamide 0.5g, sorbitan monooleate 5g, peroxide Ammonium sulfate 1.5g, potassium persulfate 0.1g, vegetable oil 150g and deionized water 100g.

[0030] The preparation method of above-mentioned polymer microsphere regulating and displacing agent comprises the following steps:

[0031] (1) Add oil and emulsifier into the reaction kettle, stir evenly to form a continuous oil phase;

[0032] (2) dissolving acrylamide, anionic surfactant, crosslinking agent, and 30% ammonium persulfate in deionized water, stirring evenly, adjusting the pH value to 6-8, and forming an aqueous phase;

[0033] (3) Potassium persulfate and remaining ammonium persulfate are dissolved in deionized water respectively to form potassium persulfate solution and ammonium persulfate solution;

[0034] (4) Add the water phase to the oil phase under the stirring condit...

Embodiment 2

[0036] The difference between Example 2 and Example 1 is that the composition of the polymer microsphere displacing agent is 25g of acrylamide, 8g of β-allyl sulfonate, 1.2g of N,N-methylenebisacrylamide, and sorbic acid Alcohol anhydride monooleate 8g, ammonium persulfate 2g, potassium persulfate 0.5g, vegetable oil 250g and deionized water 280g.

Embodiment 3

[0038] The difference between embodiment 3 and embodiment 1 is: step (2) dissolving acrylamide, anionic surfactant, crosslinking agent, 50% ammonium persulfate in deionized water, stirring evenly, adjusting the pH value to 6-8 , forming an aqueous phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com