Novel nano solid super-strong alkali catalyst and preparation and application thereof

A technology of solid super-strong base and catalyst, applied in organic chemistry, etc., can solve problems such as low yield, high reaction temperature, and long reaction time, and achieve the effects of small dosage, high catalytic activity, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

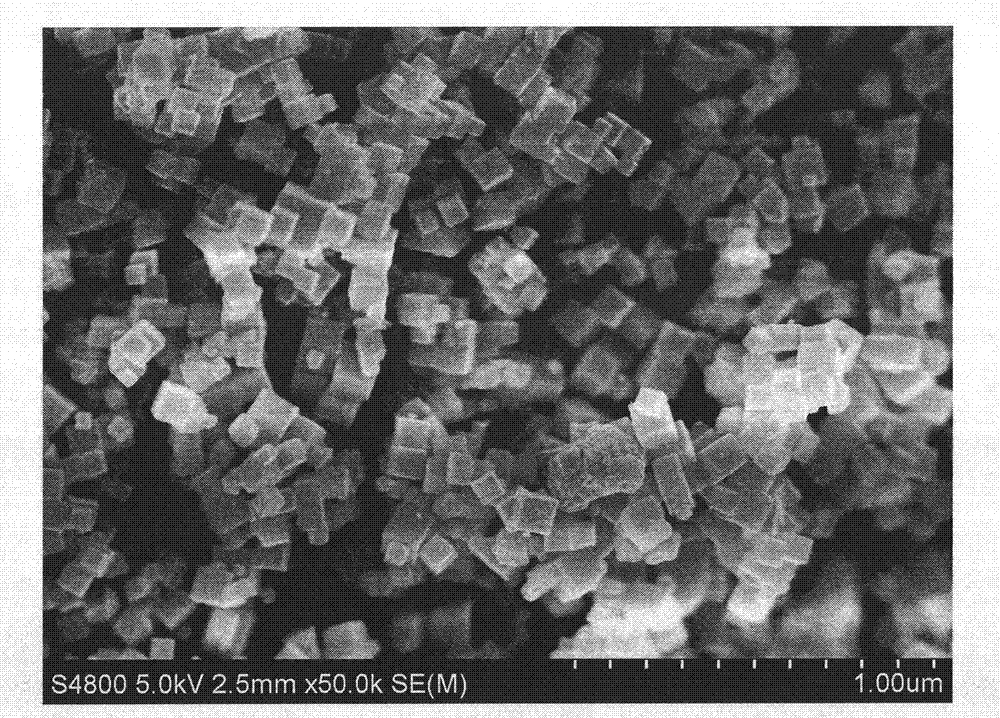

Image

Examples

Embodiment 1

[0034] Weigh 0.520 g of PVP, dissolve in 50 ml of deionized water, and stir to dissolve at room temperature. According to the ratio of Sn and Mg molar ratio of 1:1, weigh 0.766 g SnCl 4 ·5H 2 O and 0.633 g Mg(NO 3 ) 2 ·6H 2 O was successively added to the above solution and stirred for 12 h. Add 0.1 mol / L KOH solution drop by drop, adjust the pH of the system to 12-14, continue to stir for 2 h, then transfer to the hydrothermal reaction kettle, set at 180 o C in a homogeneous reactor for 24 h. After the reaction, cool to room temperature, centrifuge, wash the obtained precipitate with water until the washing liquid is neutral, wash off the surfactant with ethanol, and then place it at 120 o C oven dried for 24 h. Then take out the sample, grind it, and put it in the roaster under N 2 Atmosphere, with 5 o C / min heating rate, heating up to 600 o C is calcined for 2 h to obtain the catalyst (alkali strength is 26.5≤H_<33.0, and the corresponding alkali content is as hi...

Embodiment 2

[0037] Weigh 0.508 g CTAB, dissolve it in 60 ml deionized water, and stir to dissolve at room temperature. According to the molar ratio of Sn and Mg of 1:1, weigh 0.784 g SnCl 4·5H 2 O and 0.745g Mg(NO 3 ) 2 ·6H 2 O was added to the above solution successively and stirred for 2 h. Add 0.5 mol / L NaOH solution drop by drop, adjust the pH of the system to 12-13, continue to stir for 4 h, then transfer to the hydrothermal reaction kettle, at 180 o C in a homogeneous reactor for 24 h. After the reaction, cool to room temperature, centrifuge, wash the obtained precipitate with water until the washing liquid is neutral, wash off the surfactant with ethanol, and then place it at 120 o C oven dried for 24 h. Then take out the sample, grind it, and put it in the roaster under N 2 Atmosphere, with 8 o C / min heating rate, heating up to 550 o C was calcined for 2 h to obtain the catalyst (alkali strength 26.5≤H_≤33.0, corresponding alkali amount up to 0.423mmol / g).

[0038] Tak...

Embodiment 3

[0040] Weigh 0.521 g of P123, dissolve in 50 ml of deionized water, and stir to dissolve at room temperature. According to the ratio of Sn and Mg molar ratio of 1:1, weigh 0.763 g SnCl 4 ·5H 2 O and 0.569 g Mg(NO 3 ) 2 ·6H 2 O was successively added to the above solution and stirred for 5 h. Add 0.5 mol / L KOH solution drop by drop, adjust the pH of the system to 12-13, continue to stir for 2 h, then transfer to the hydrothermal reaction kettle, at 180 o C in a homogeneous reactor for 24 h. After the reaction, cool to room temperature, centrifuge, wash the obtained precipitate with water until the washing liquid is neutral, wash off the surfactant with ethanol, and then place it at 120 o C oven dried for 24 h. Then take out the sample, grind it, and put it in the roaster under N 2 Atmosphere, with 2 o C / min heating rate, heating up to 600 o C was calcined for 2 h to obtain the catalyst (alkali strength 26.5≤H_≤33.0, corresponding alkali amount up to 0.418mmol / g).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com