Cold-end falling plate lifting device used in float glass production line

A float glass and lifting device technology, which is applied in glass production, glass manufacturing equipment, glass transportation equipment, etc., can solve the problems of glass plate collision, bearing impact, and easy damage of bearings, so as to prolong the service life and avoid wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The cold-end dropping plate lifting device in the float glass production line of the present invention will be further described in detail through specific examples below.

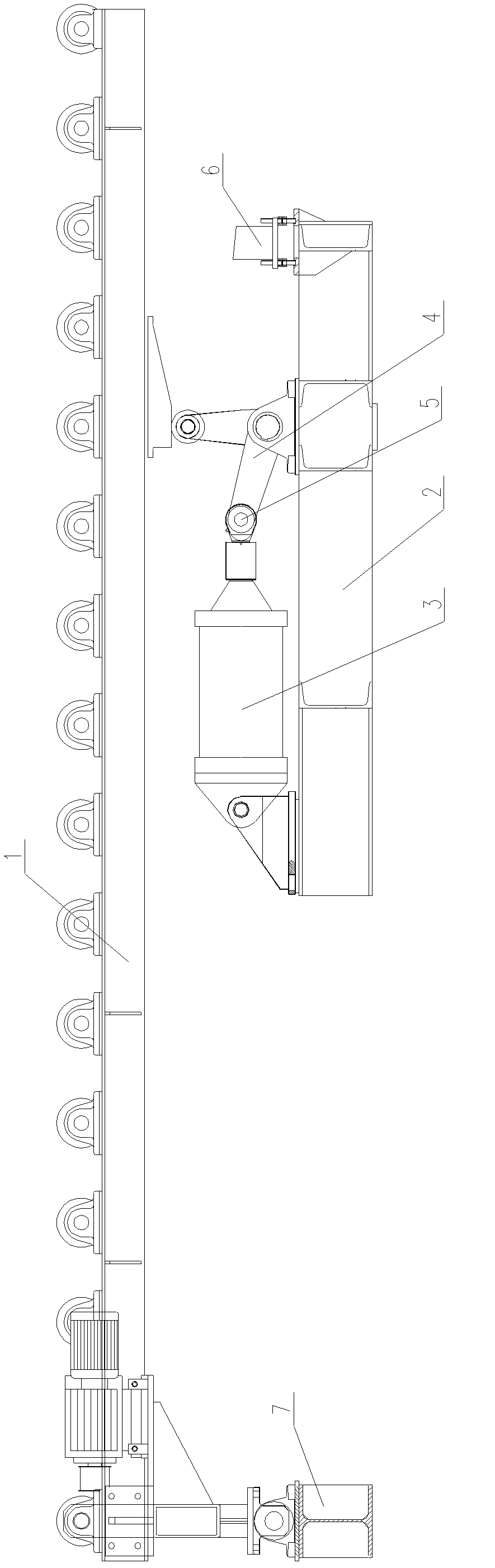

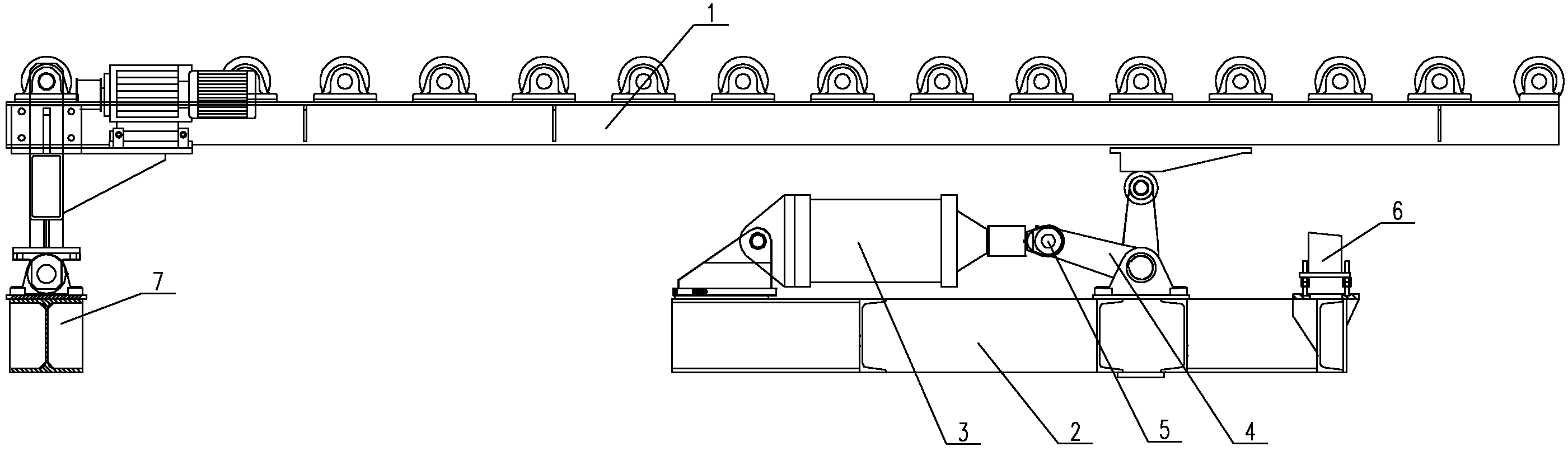

[0010] Such as figure 1 As shown, the cold-end falling plate lifting device in the float glass production line includes a frame 2, a cylinder 3, and a V-shaped crank 4 arranged under the cold-end falling plate 1. The base of the cylinder 3 is hinged on the frame 2, and the crank The corner of 4 is hinged with frame 2, one end of crank 4 is hinged with cold end drop plate 1, and the other end of crank 4 is connected with the piston rod of cylinder 3 through joint bearing 5. In order to prevent that when the cylinder 3 breaks down, the cold end drop plate 1 will fall unrestrictedly and cause damage to the cold end drop plate 1 and glass damage, the frame 2 is provided with a limit block 6 for limiting the cold end drop plate 1 to continue to descend.

[0011] The working principle of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com