Preparation method for composite film on titanium alloy surface and solution formula thereof

A surface composite and titanium alloy technology, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of difficult industrial application, weak film binding force, and inability to process shapes, etc., to achieve improved bonding strength and low cost. Low, the effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is a kind of preparation method of titanium alloy surface composite film layer and solution formula thereof, and the steps of its method are:

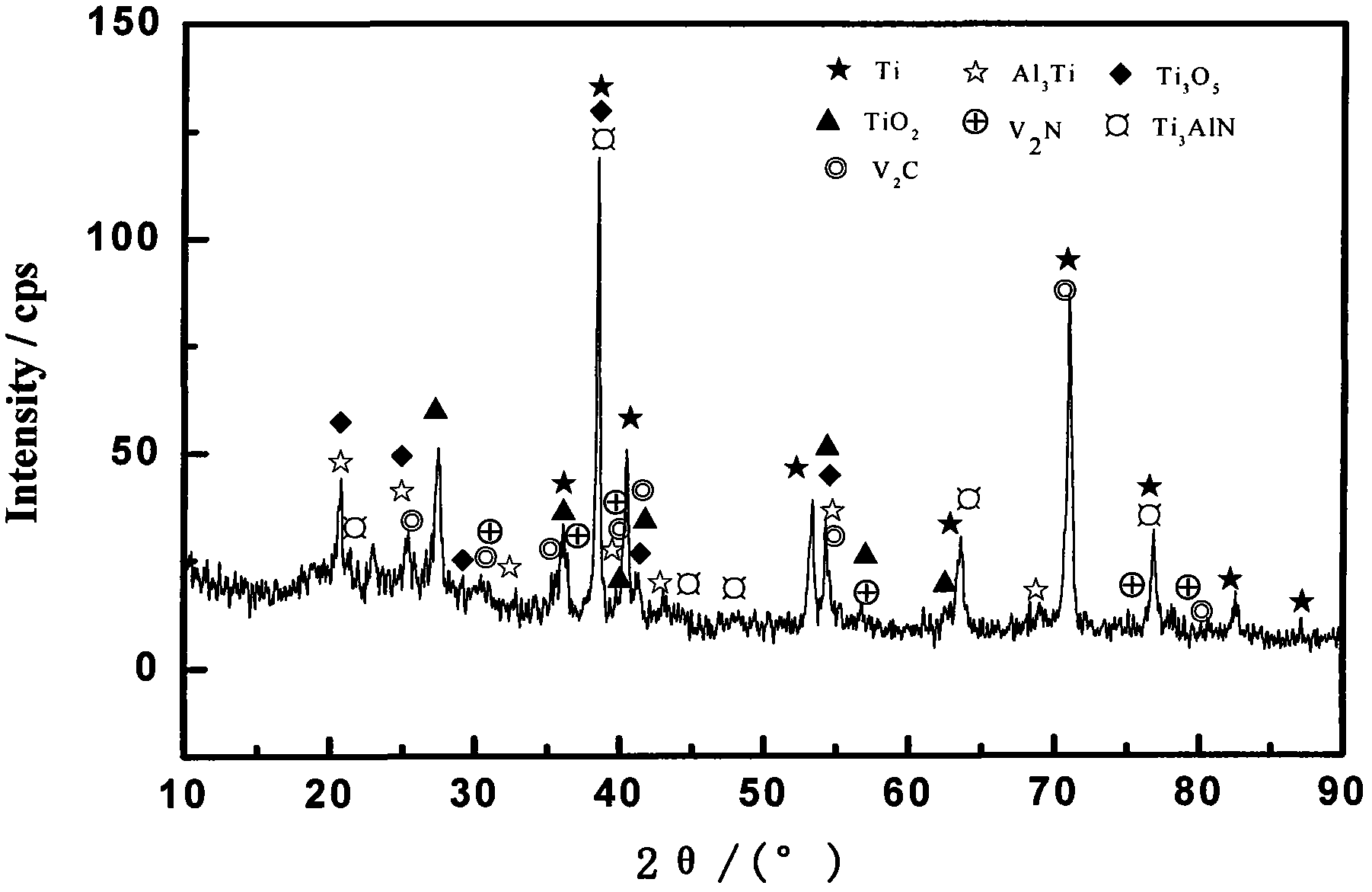

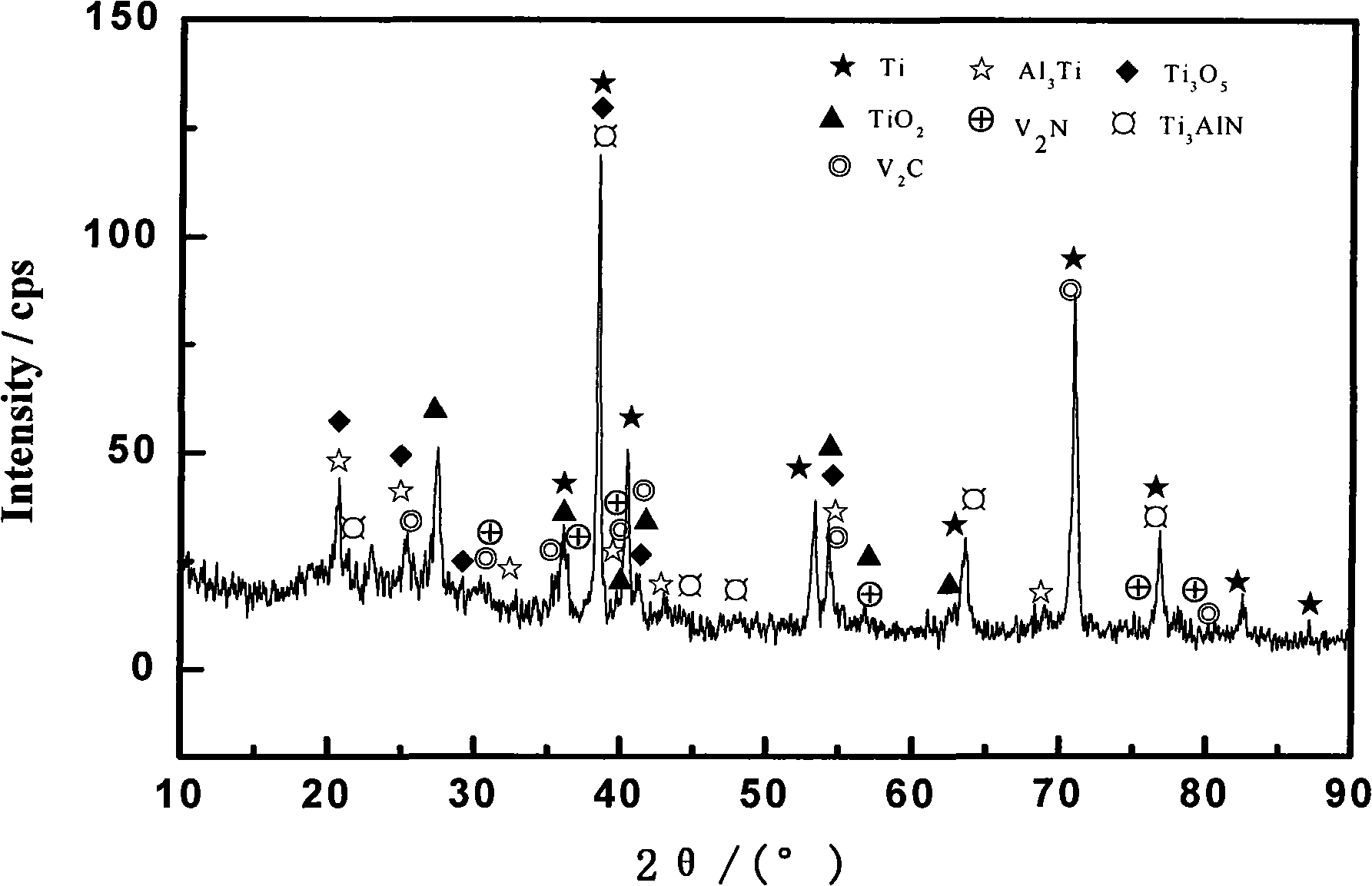

[0017] (1) Put the polished and cleaned titanium alloy workpiece in the electrolyte solution containing the elements to be infiltrated, and first perform plasma electrolytic infiltration treatment, and form a surface modification layer containing the distribution of infiltrated elements on its surface;

[0018] (2) After the workpiece to be processed is cleaned, it is placed in an alkaline electrolyte for plasma electrolytic oxidation treatment, and finally a composite film with high hardness, corrosion resistance, wear resistance and friction reduction is obtained on the surface of the workpiece. layer.

[0019] According to the preparation method described above, the titanium alloy workpiece is connected to the electrode of the power supply during the plasma electrolytic infiltration treatment, the voltag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap