Air-conditioning system with auxiliary defrosting system

An auxiliary system and air-conditioning system technology, applied in the field of HVAC, can solve the problems of general defrosting speed, large environmental impact of air-conditioning space, and increased energy consumption, and achieve clean defrosting, accelerated defrosting, and high defrosting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

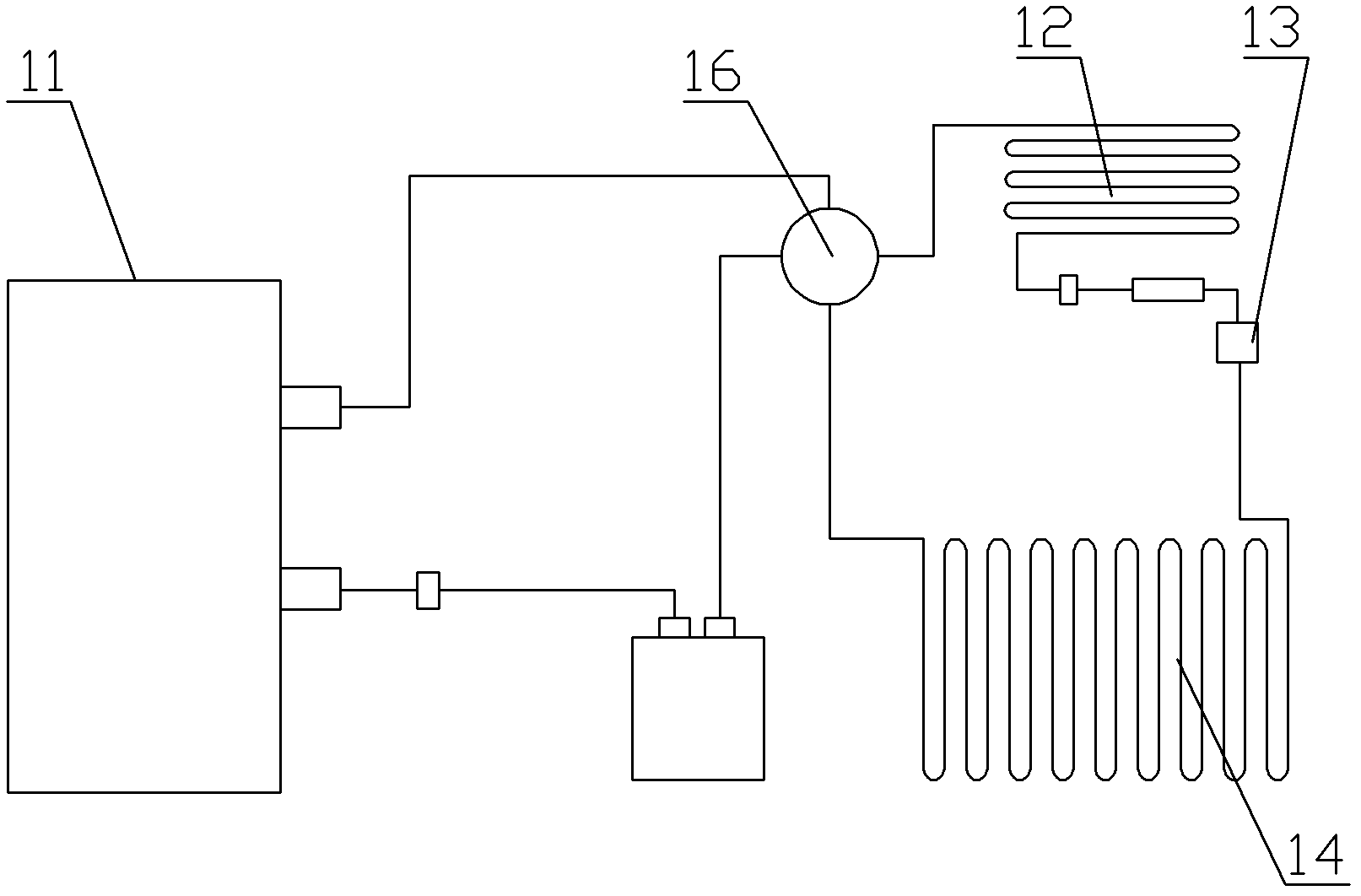

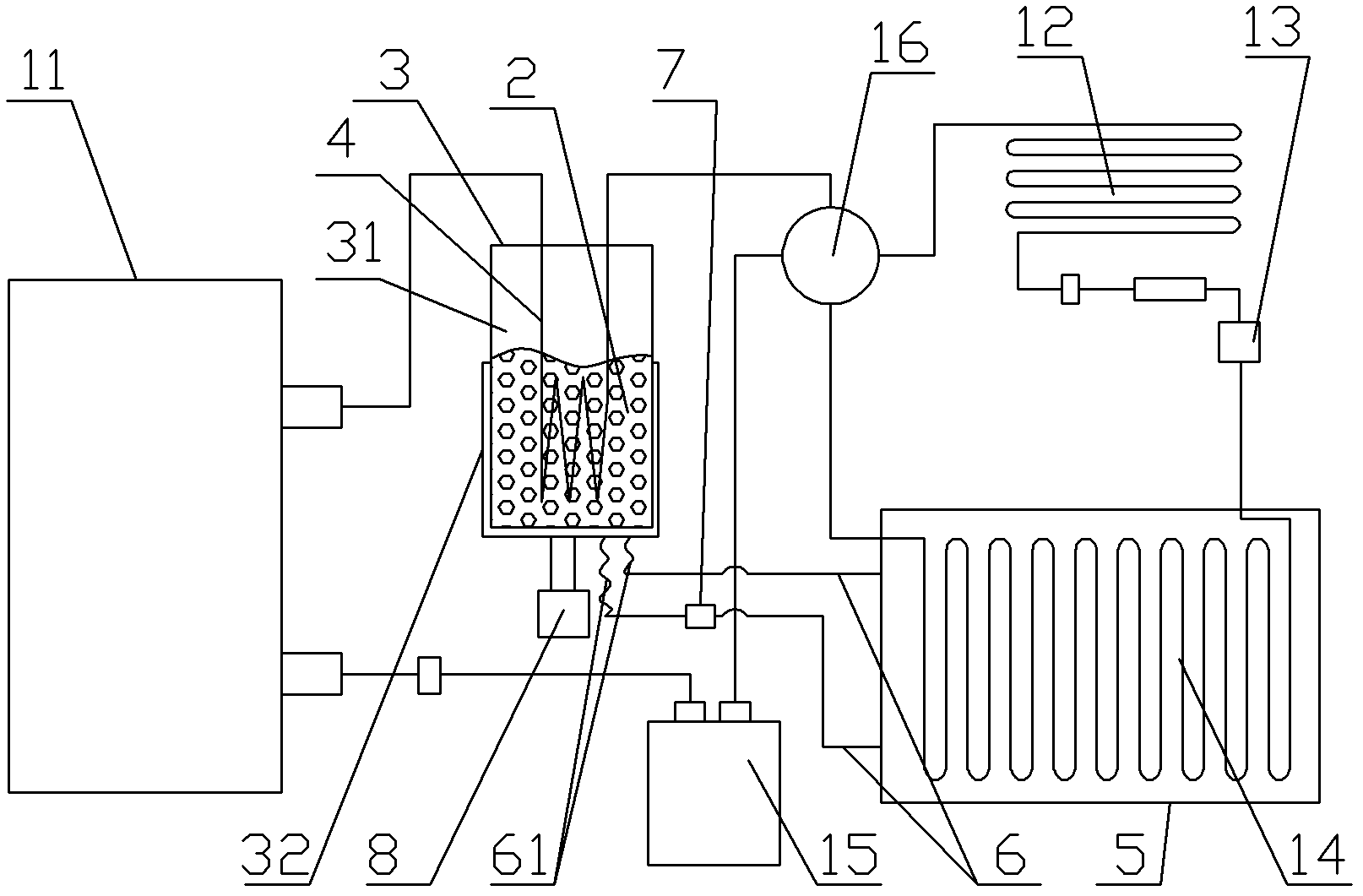

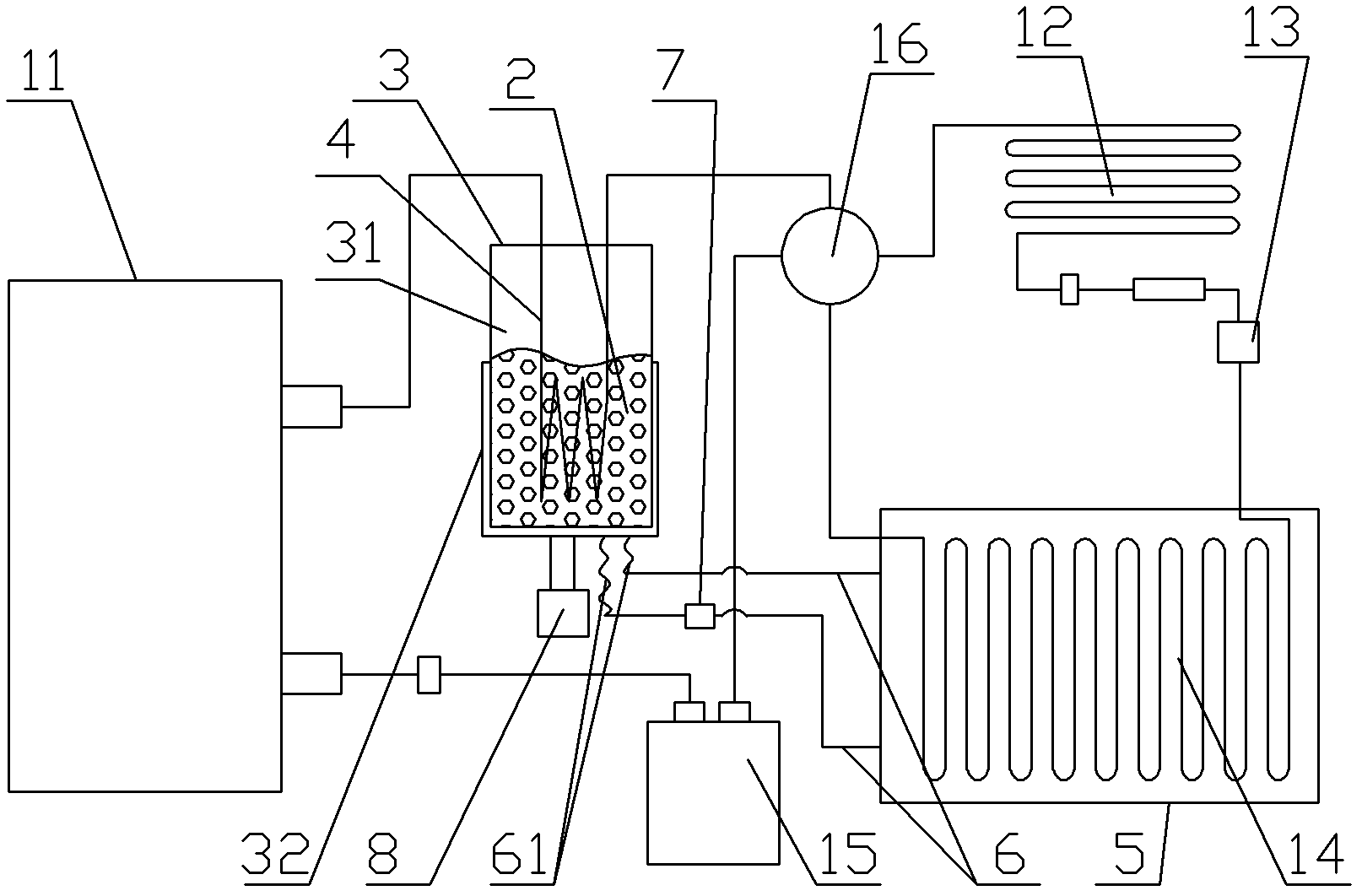

[0009] Such as figure 2 As shown, it is an air conditioning system with a defrosting auxiliary system according to the present invention, including a compressor 11, a condenser 12, a throttle valve 13, an evaporator 14, a vapor-liquid separator 15, a four-way reversing valve 16, and a four-way Reversing valve 16 communicates with the gas outlet of described compressor 11, the inlet of gas-liquid separator 15, evaporator 14, condenser 12 respectively, and the outlet of gas-liquid separator 15 communicates with the gas return port of compressor 11, also includes The energy storage tank 3 containing the energy storage medium 2 inside, the pipeline 4 between the air outlet of the compressor and the four-way reversing valve passes through the energy storage medium 2 in the energy storage tank, and the rear part of the evaporator 14 is also provided with There is a defrosting cooling device 5, the defrosting cooling device 5 can adopt a heating pipeline with many fins, and can also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com