Finned tube structure with solar heat collection function

A solar heat collection and finned tube technology, which is applied in the field of finned tube structures, can solve the problems of low refrigerant evaporation temperature, reduced air heat exchange, and influence on heating effect, and achieves accelerated defrosting, increased evaporation temperature, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

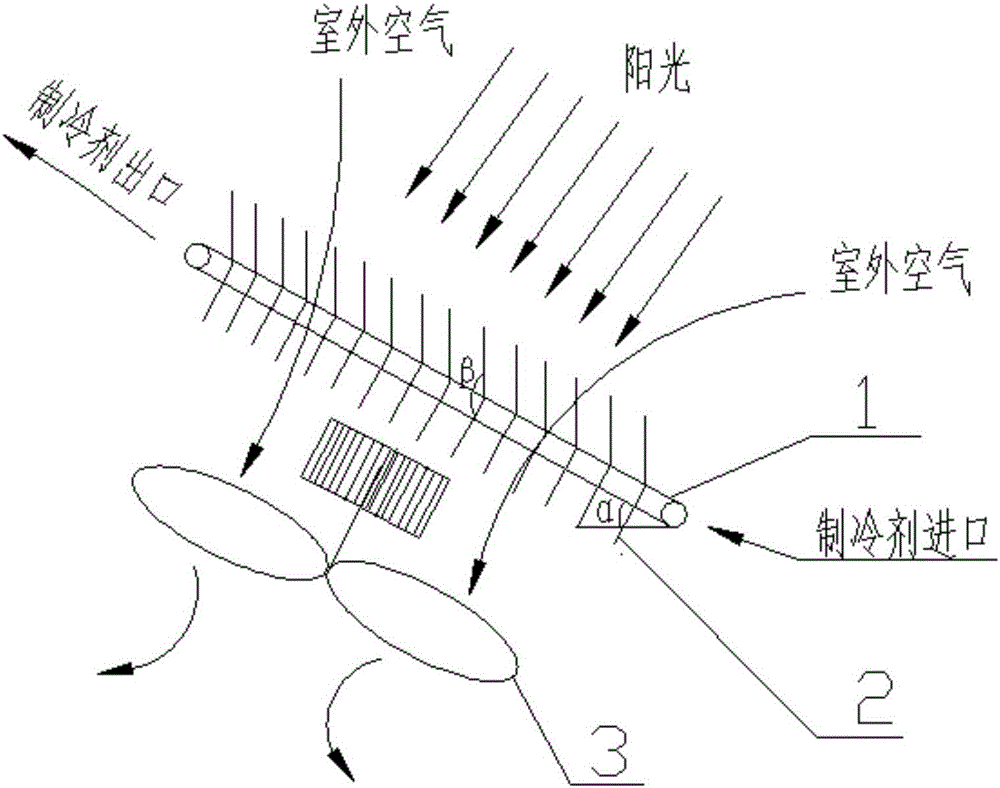

[0021] Specific implementation mode one, combining figure 1 and figure 2 Describe this embodiment, the first finned tube structure with solar heat collection function described in this embodiment, the structure includes heat exchange tubes 1, fins 2, and fans 3, and the heat exchange tubes 1 participate in heat exchange The parts of the heat exchange tubes 1 are parallel to each other and the angle α between the tube length direction and the horizontal ground takes a value within φ-15°~φ+15°, where φ is the local latitude, and the plane where the parallel parts of the heat exchange tubes 1 are located is the same as the horizontal ground The value of the included angle is the same as α, the lower half of the fin 2 is perpendicular to the heat exchange tube 1, and the included angle β between the upper half of the fin 2 and the lower half of the fin is obtuse angle.

[0022] The angle β between the upper half of the fin and the lower half of the fin 2 satisfies the following...

specific Embodiment approach 2

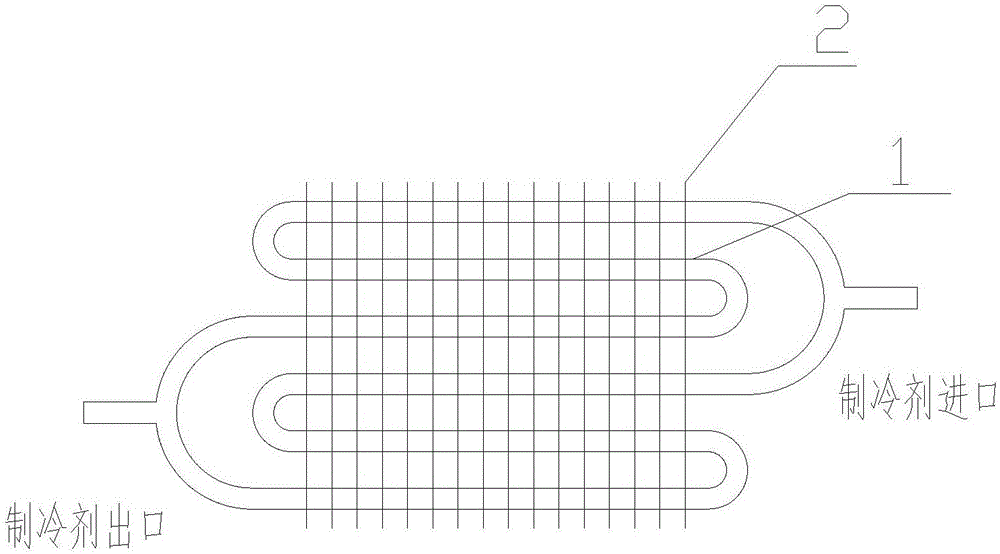

[0024] Embodiment 2, this embodiment is basically the same as Embodiment 1, the difference lies in the connection method of the heat exchange tube 1, such as figure 1 and image 3 shown.

specific Embodiment approach 3

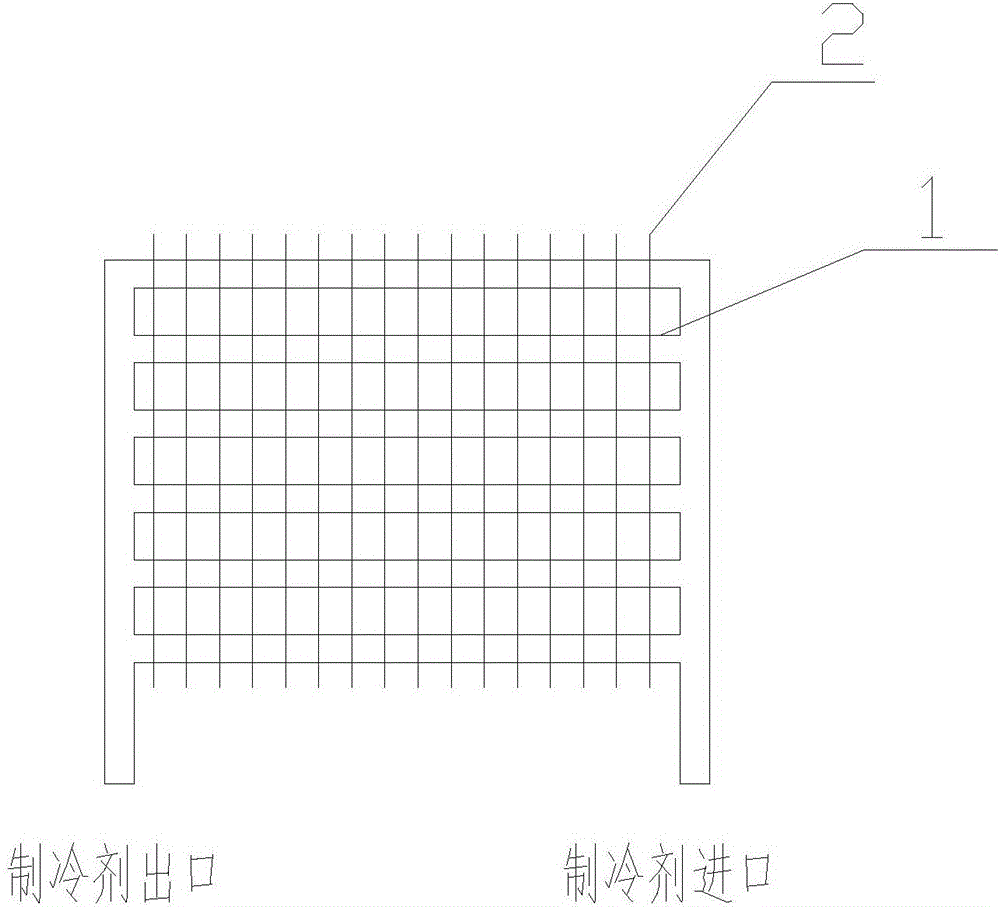

[0025] Embodiment 3, this embodiment is basically the same as Embodiment 1 and Embodiment 2, the difference is that the fins in the upper half of the fins 2 are perpendicular to the heat exchange tube 1, as Figure 4 shown. The third finned tube structure with solar heat collection function described in this embodiment, the structure includes heat exchange tubes 1, fins 2, and fans 3, and the parts of the heat exchange tubes 1 participating in heat exchange are parallel to each other and The angle α between the tube length direction and the horizontal ground is the local latitude. The angle between the plane where the heat exchange tubes 1 are parallel to each other and the horizontal ground is the same as α. The upper half of the fin 2 is connected to the heat exchange The tube 1 is vertical, the angle β between the fins in the upper part and the fins in the lower part is 160°, the spacing L between the fins 2 is 1.5 mm, the fin height h is 12 mm, and the outer diameter d of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com