Combined metering device and combined metering method thereof

A combined measurement and optimal combination technology, applied in measuring devices, weighing, instruments, etc., can solve the problems of reducing the combined metering accuracy, affecting the combined metering accuracy, affecting the discharge weight value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

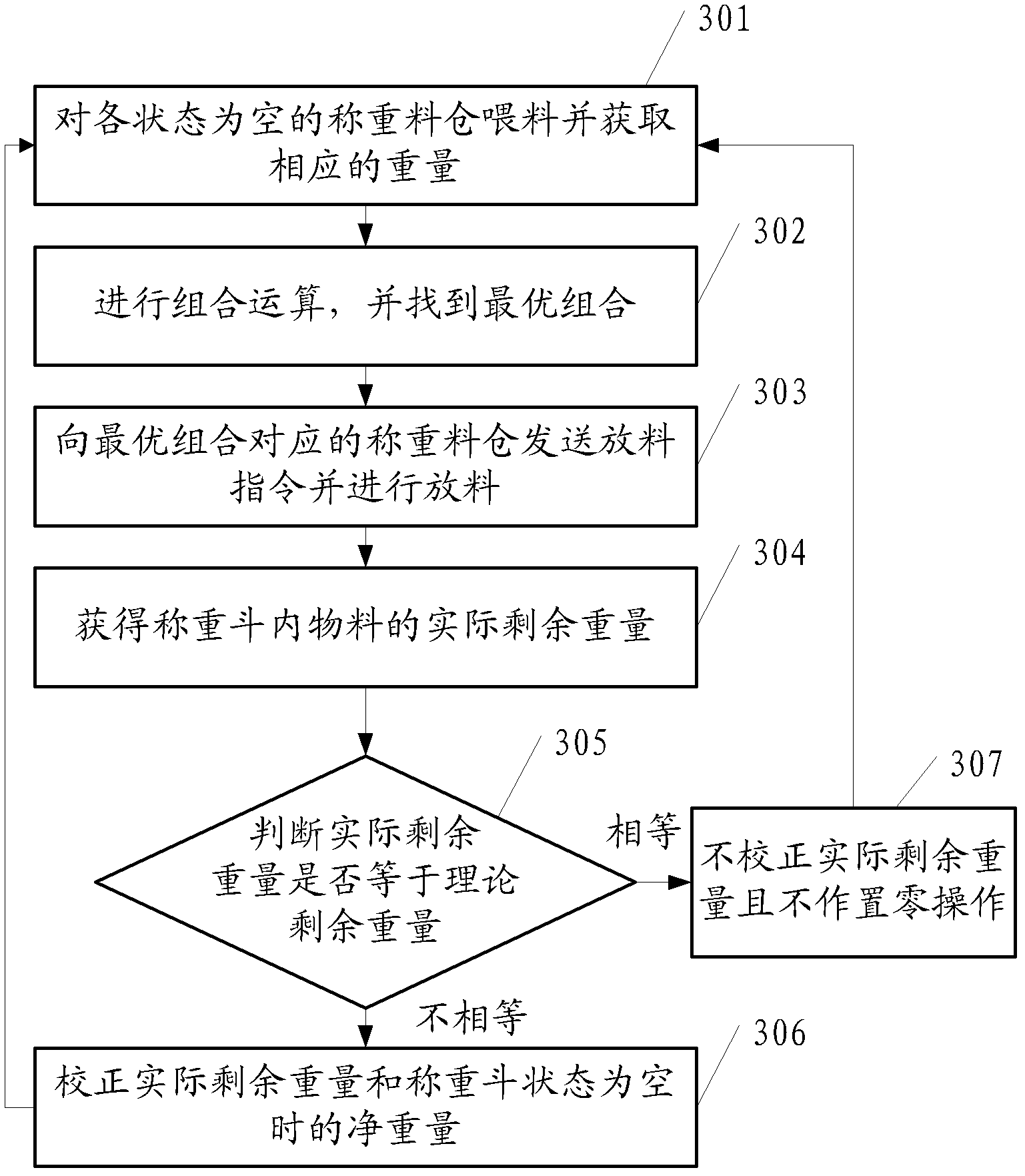

[0033] The present invention will be described below in conjunction with the accompanying drawings.

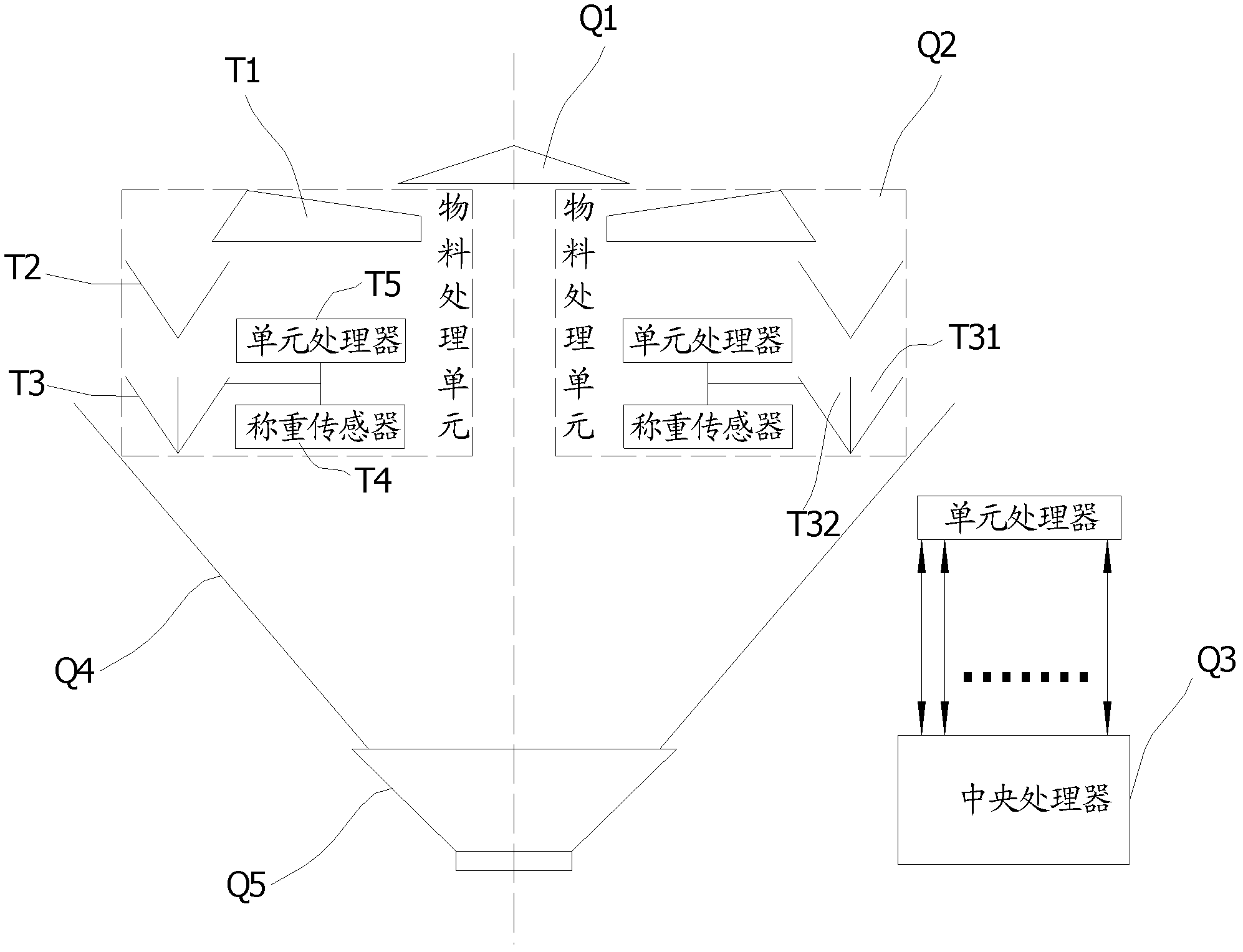

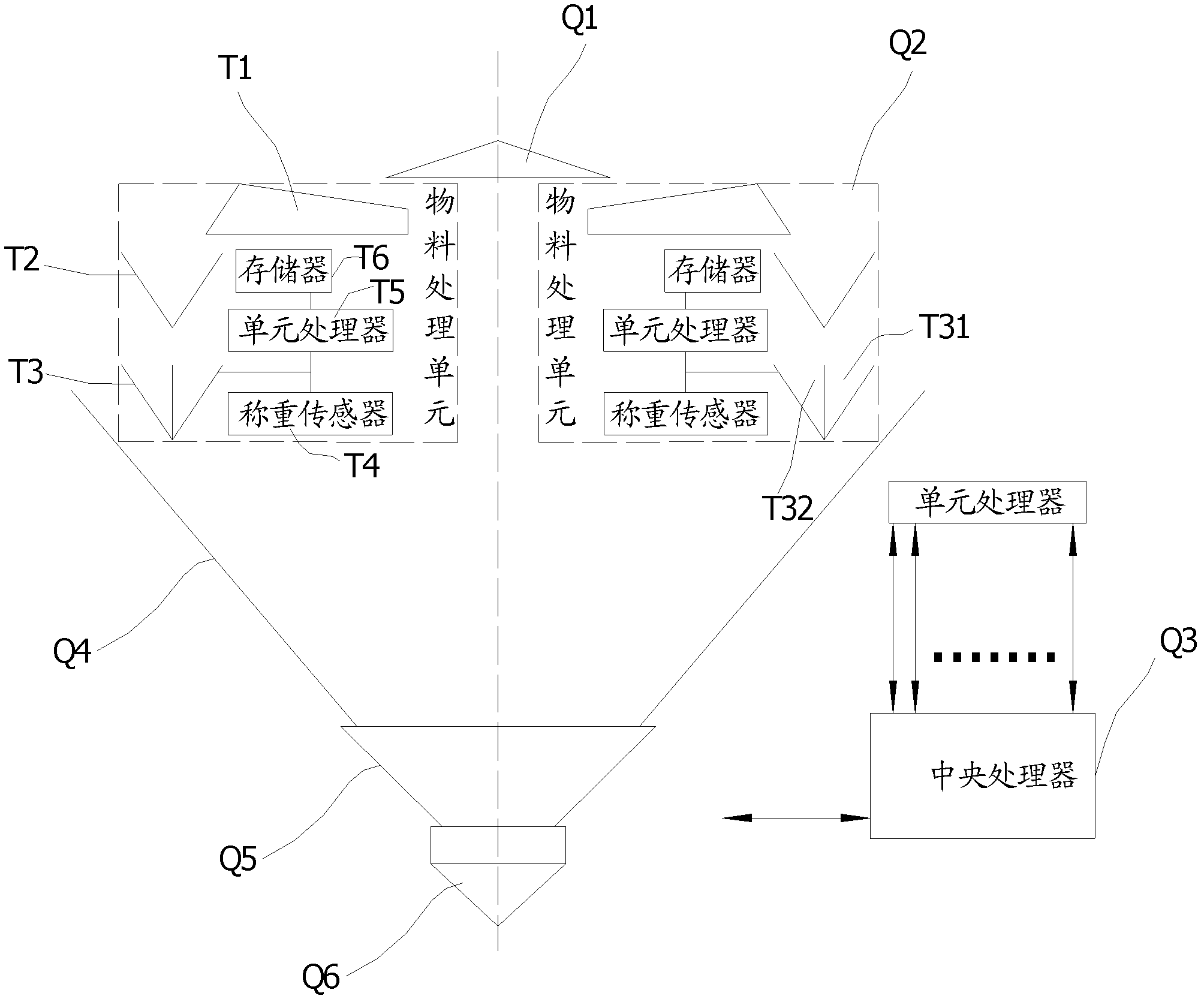

[0034] See figure 1 First, a combination metering device disclosed in the present invention is introduced, which includes a main vibration plate Q1 arranged on the upper part of the main body middle seat, several material processing units Q2 arranged at equal intervals on the circumference of the main body middle seat, and arranged below the material processing unit Q2 A collection mechanism including a collection chute Q4 and a discharge tray Q5; the combined metering device is also equipped with a central processing unit Q3 that controls the related actions of the combined metering device; wherein, each material processing unit Q2 is correspondingly equipped with a cable from top to bottom Vibrating plate T1, buffer bucket T2, and weighing bucket T3 with two weighing bins (T31 and T32), each material processing unit Q2 is also equipped with a weighing sensor T4; the weighing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com