Performance test bench for electric spindle

A technology of electric spindle and test bench, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as difficulty in meeting the measurement requirements of high-speed electric spindles, achieve high-speed speed measurement, simple structure, Measuring Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

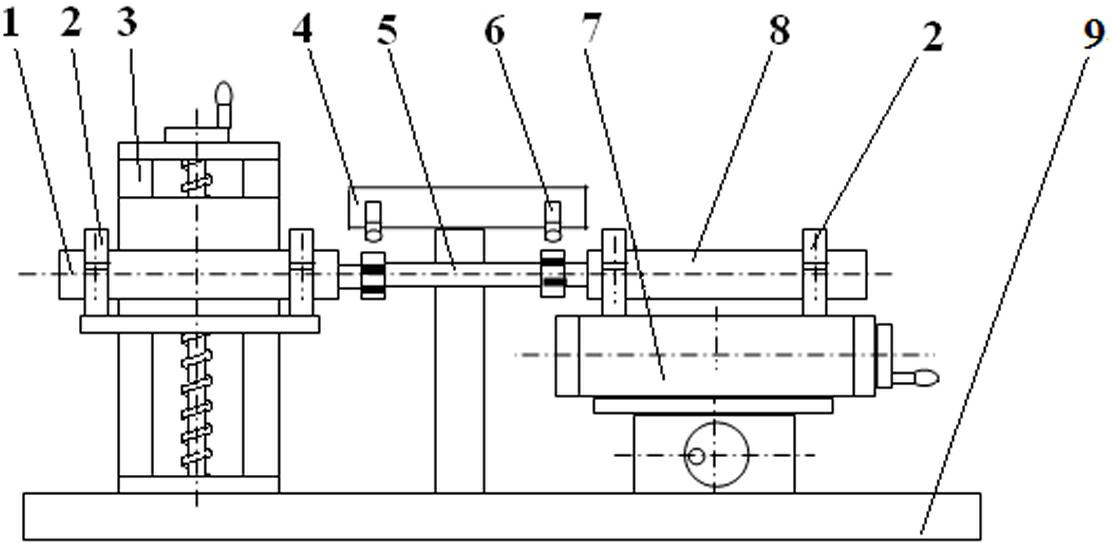

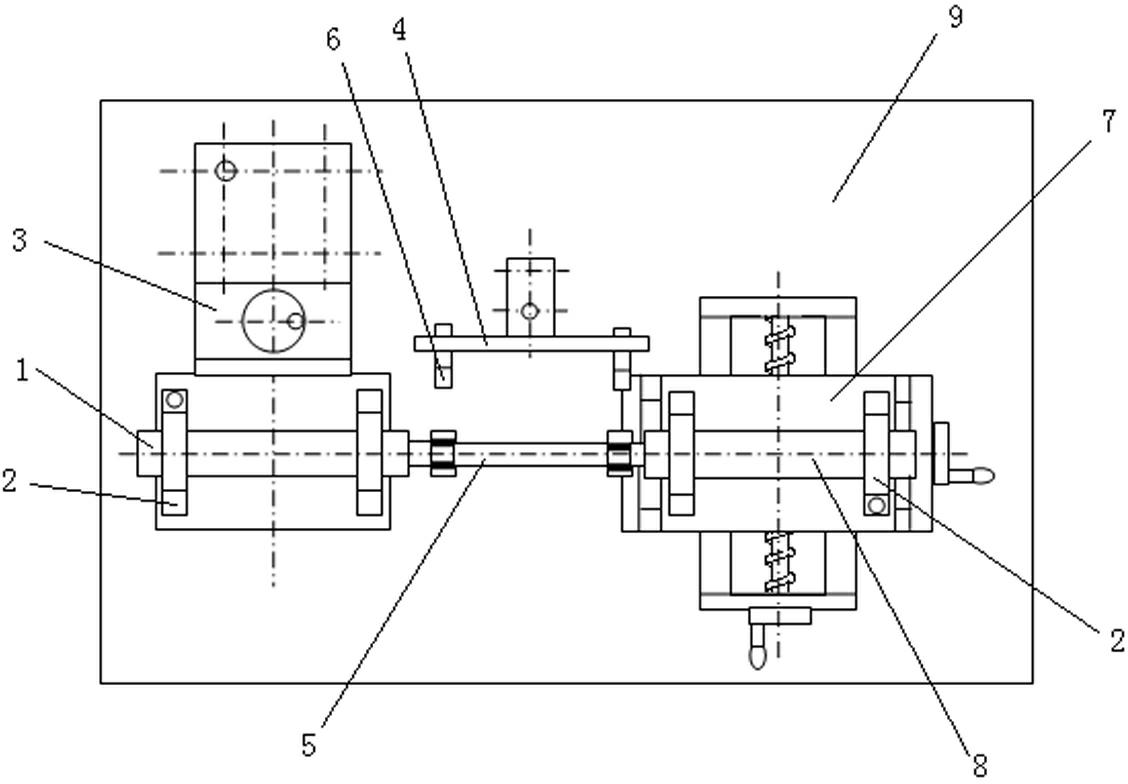

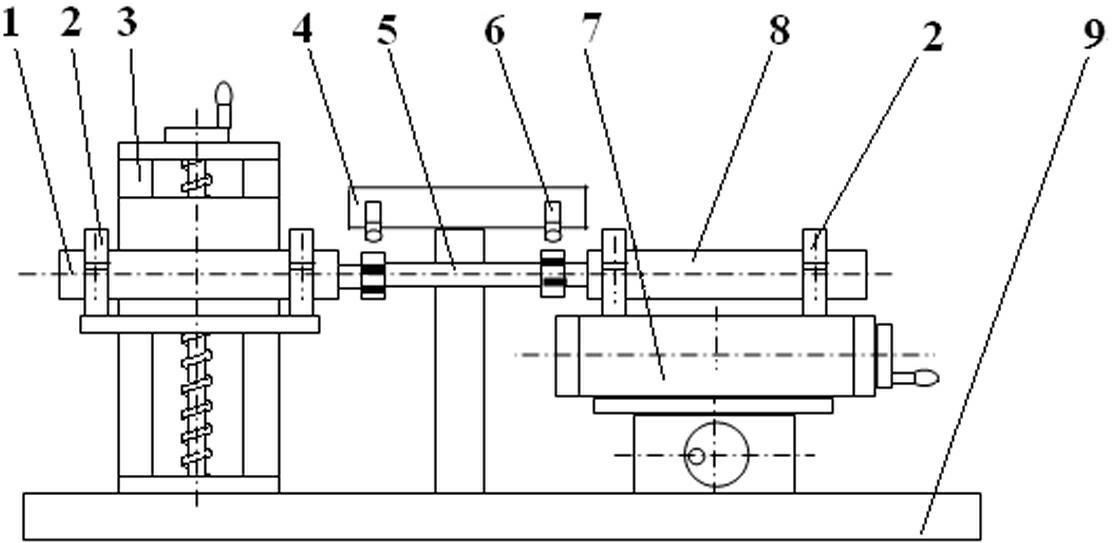

[0012] The present invention will be further described in detail below with reference to the drawings and embodiments.

[0013] See figure 1 This embodiment includes a horizontal installation platform 9 on which a lifting platform 3 and a cross platform 7 are fixed, and a V-shaped mounting frame 2 is fixed on both the lifting platform and the cross platform. Combine figure 2 , The lifting platform 3 adopts a screw method to move up and down. The cross platform 7 includes a horizontal platform and a vertical platform. The horizontal platform is located on the vertical platform and forms a cross shape with each other. The horizontal platform uses a screw to move left and right, and the vertical platform uses a wire. The lever way realizes the movement back and forth. The installation platform 9 provides a high-precision plane reference for the equipment installed on it.

[0014] It can be seen from the figure that the loading electro-spindle 1 is installed on the V-shaped mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com