Drilling parameter monitoring device and monitoring method of underground drilling machine

A drilling parameter and monitoring device technology, applied in the field of control engineering and geological engineering research, can solve the problems of complex and changeable rock formations, difficult to detect, and prone to errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

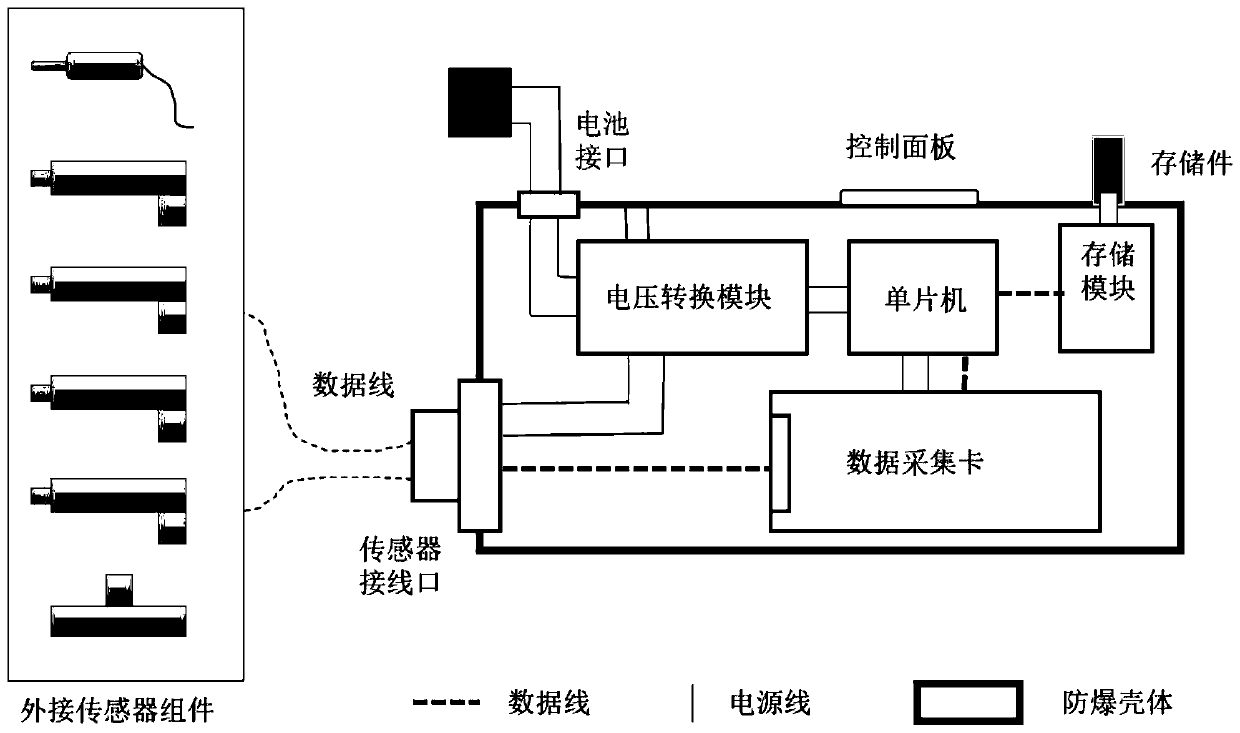

[0028] like figure 1 As shown, the present invention provides a kind of downhole drilling rig drilling parameter monitoring device, comprising:

[0029] Shell, used to protect data acquisition components and downhole power supply components;

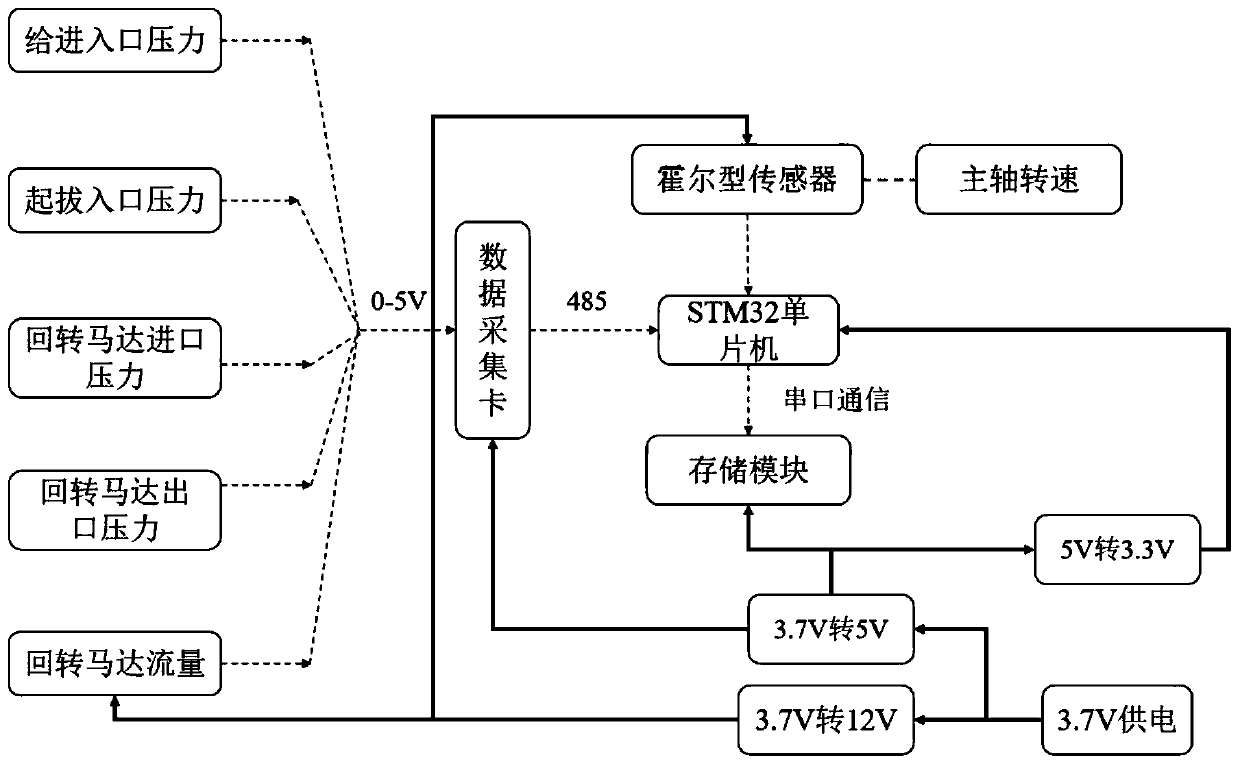

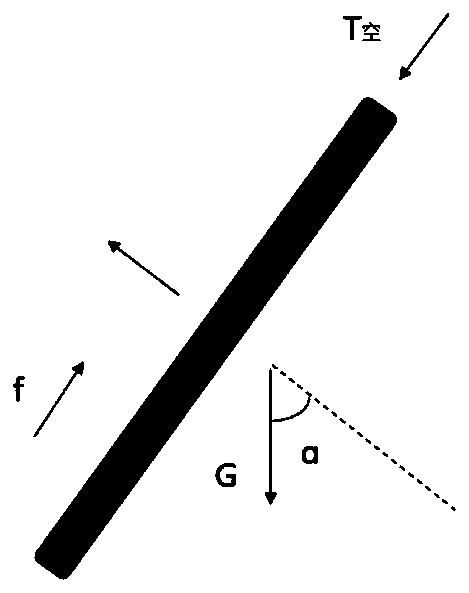

[0030] An external sensor assembly, which is arranged on the outside of the casing and on the drilling rig, is used to sense the operating parameters of drilling, such as the drilling pressure, flow rate and rotational speed. The drilling pressure is one of the most important regulation parameters in the drilling process , indicating the axial load on the drill bit during the drilling process of the drilling rig. The rotary power mechanism of the full hydraulic power head drilling rig is that the hydraulic pump drives the hydraulic mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com