Device and method for measuring axial force of working roll of slab strip hot rolling mill

A measuring device and work roll technology, which is applied in the direction of length measuring device, metal rolling, manufacturing tools, etc., can solve the problems of shutdown, lock door screw breaking, etc., and achieve the effect of convenient assembly and disassembly and direct measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

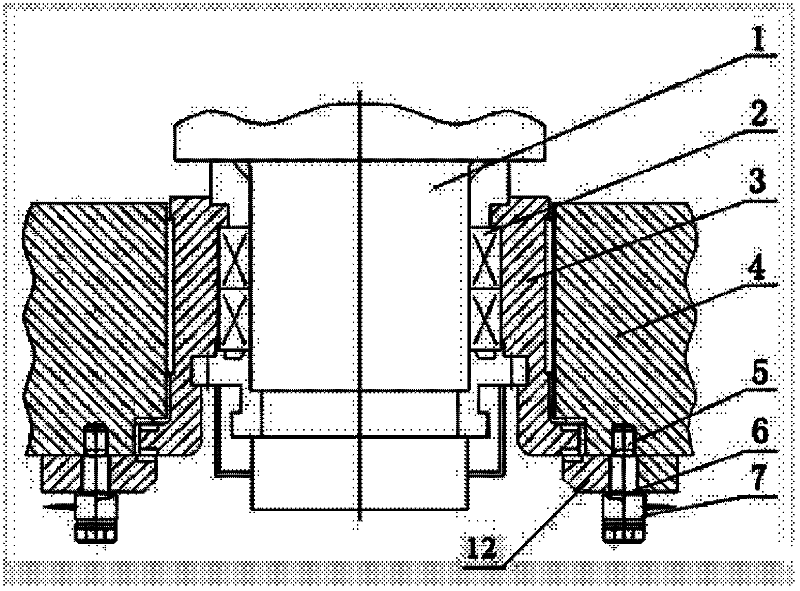

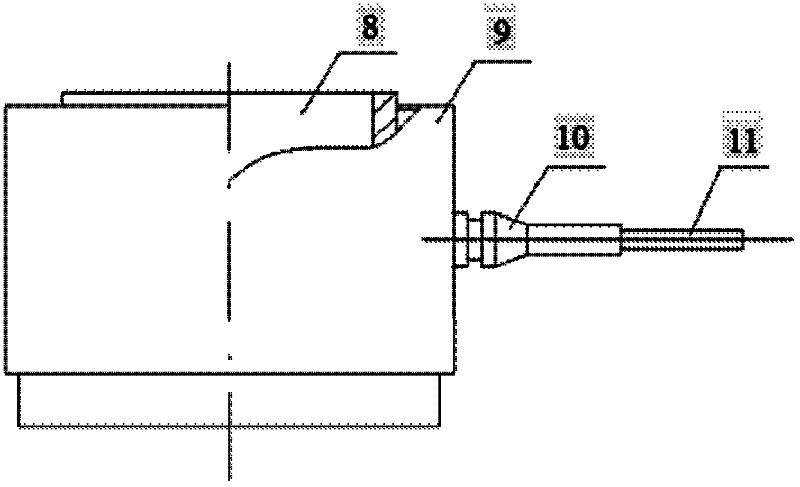

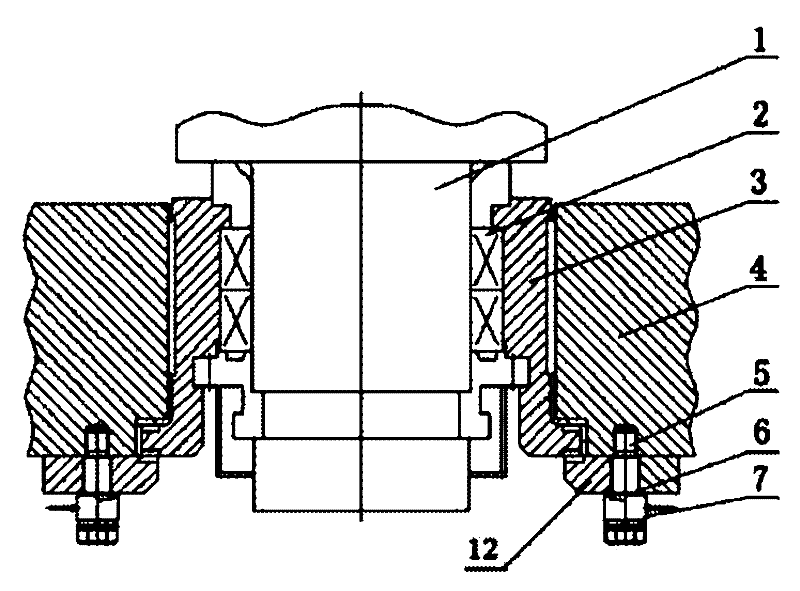

[0009] Below in conjunction with accompanying drawing, the measuring device and the method of the working roll axial force of the strip hot rolling mill of the embodiment of the present invention are described in further detail: as figure 1 Shown: Provide a measuring device for the axial force of the work roll of the strip hot rolling mill, mainly including the work roll 1, the bearing 2, the bearing seat 3, the rolling mill frame 4, and the door lock plate 12, and the feature is: the design has an extended lock door plate Screw 5, by lengthening the lock door plate screw 5, the rolling mill frame 4 and the lock door plate 12 are fixedly connected together, and a force sensor 7 is set on the inner side of the lengthened lock door plate screw 5 nut and the outside of the lock door plate 12, and the lengthened lock door plate Between the door lock plate 12 of suit on the screw 5 and the load cell 7, there is an equal load pad 6 for improving the stress of the sensor; on each side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com