Connection structure for tool bit and handle of hair clipper

A connection structure and hair clipper technology, applied in metal processing and other directions, can solve the problems of laborious disassembly process, reduced service life, loose cutter head, etc., and achieve the effect of stable disassembly process, long service life and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

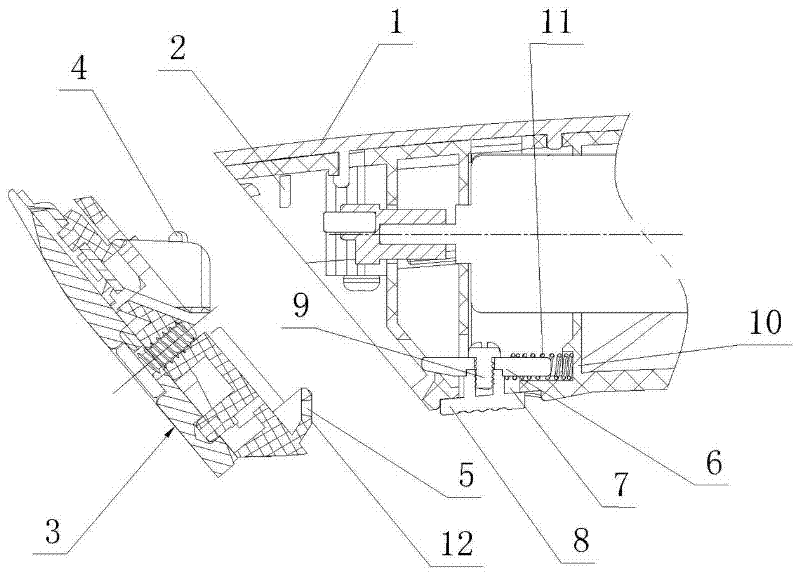

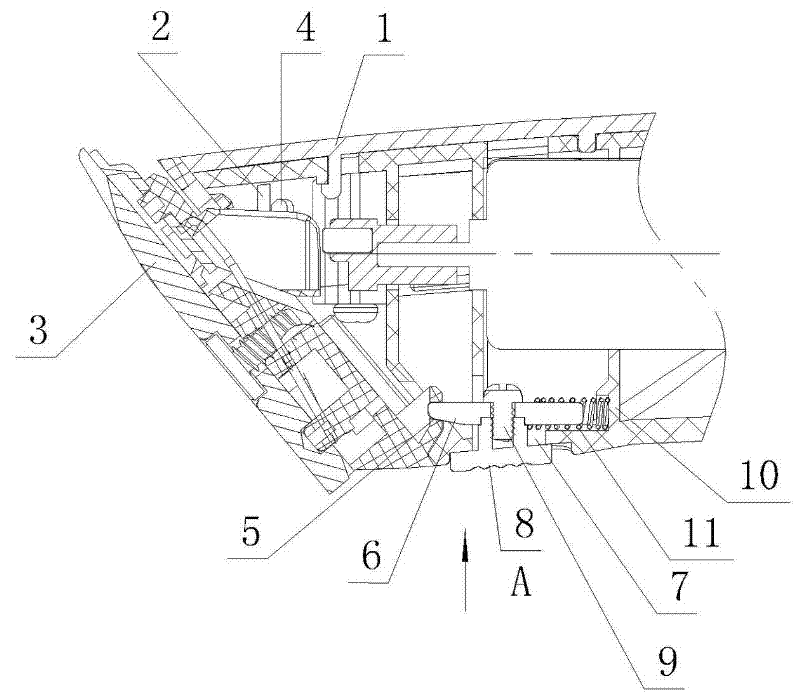

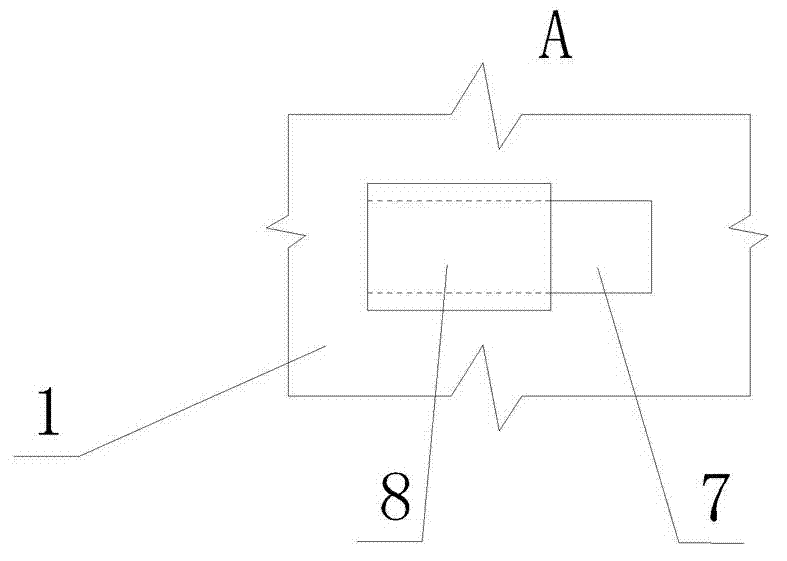

[0014] Such as figure 1 , figure 2 , image 3 The connection structure between the cutter head and the handle of the hair clipper of the present invention is shown, which includes a baffle 2 arranged on the inner side wall of the handle 1 and a projection 4 provided on the cutter head 3 for hooking with the baffle 2 . A pin hole 5 is also provided on the cutter head 3 , specifically, a protruding plate 12 is provided at the rear portion of the cutter head 3 , that is, near the handle 1 , and the pin hole 5 is located on the protruding plate 12 . A latch 6 for cooperating with the pin hole 5 is provided in the handle 1 , and the front end of the latch 6 , that is, the end close to the cutter head 3 , can be inserted into the pin hole 5 . A bar-shaped through hole 7 runs through the side wall of the handle 1, and a push button 8 is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com