Aggregate proportioning door with adjustable opening degree

A material door and aggregate technology, applied in the direction of selling raw material supply devices, etc., can solve the problems of inaccurate measurement, aggregate stuck on the door, etc., to achieve the effect of ensuring resource utilization, maximizing, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

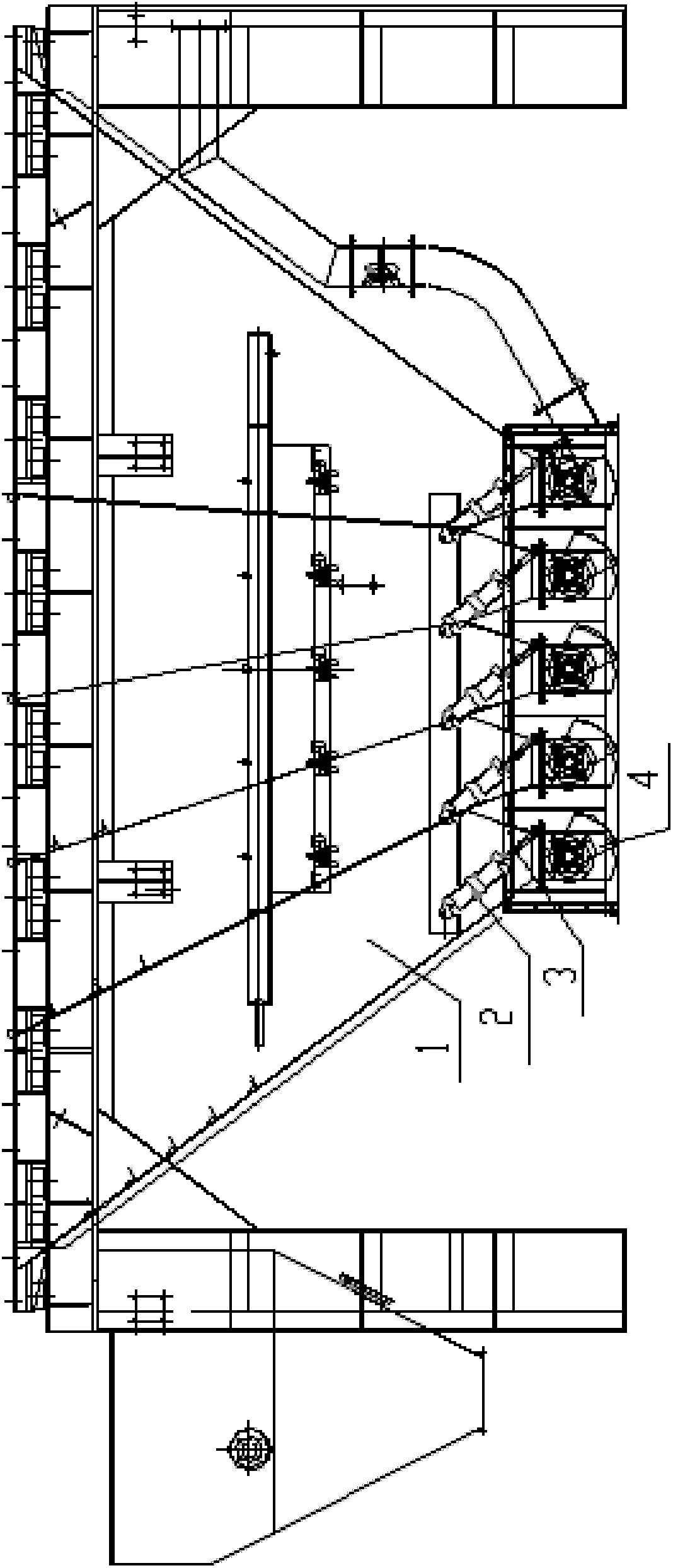

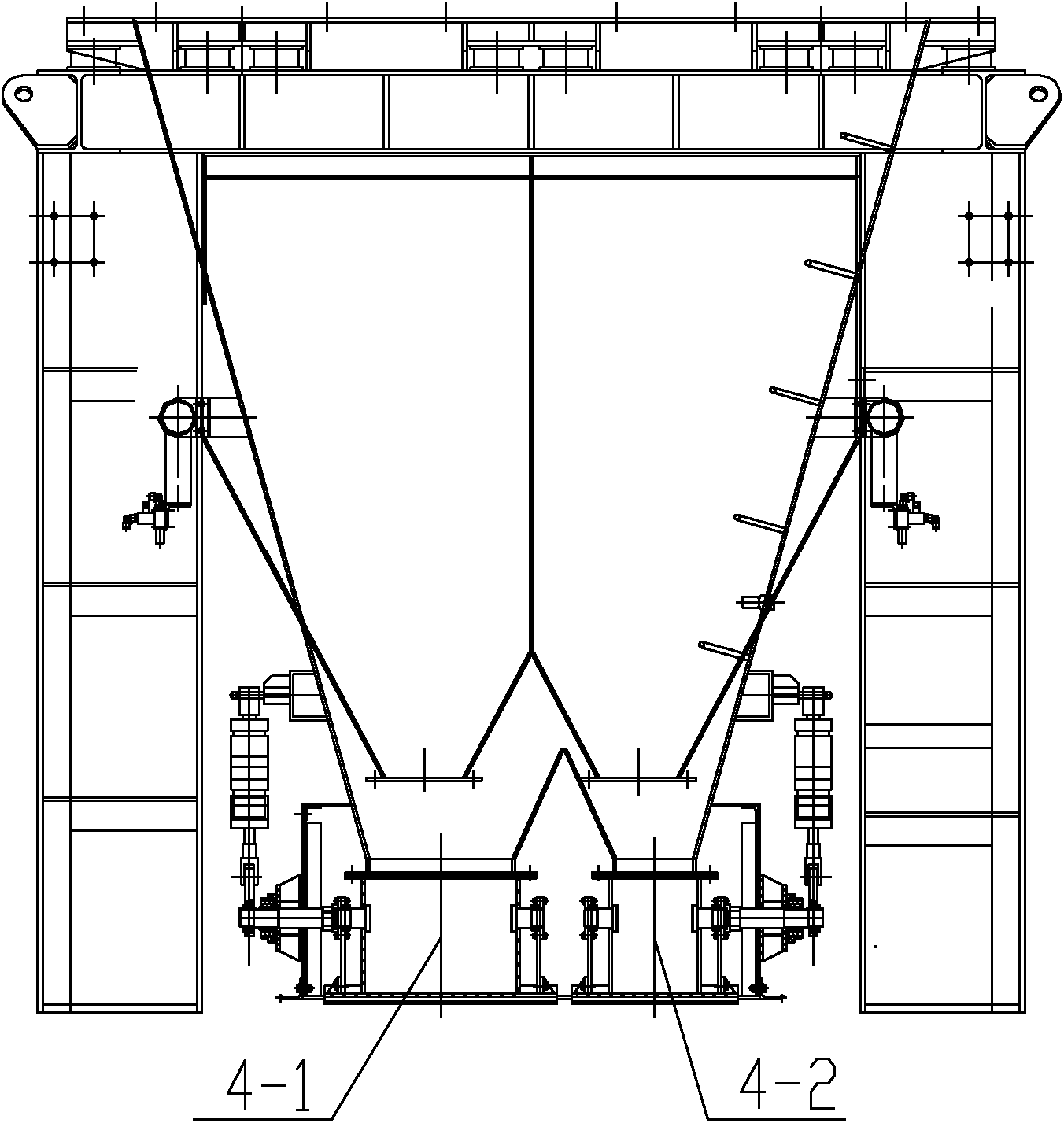

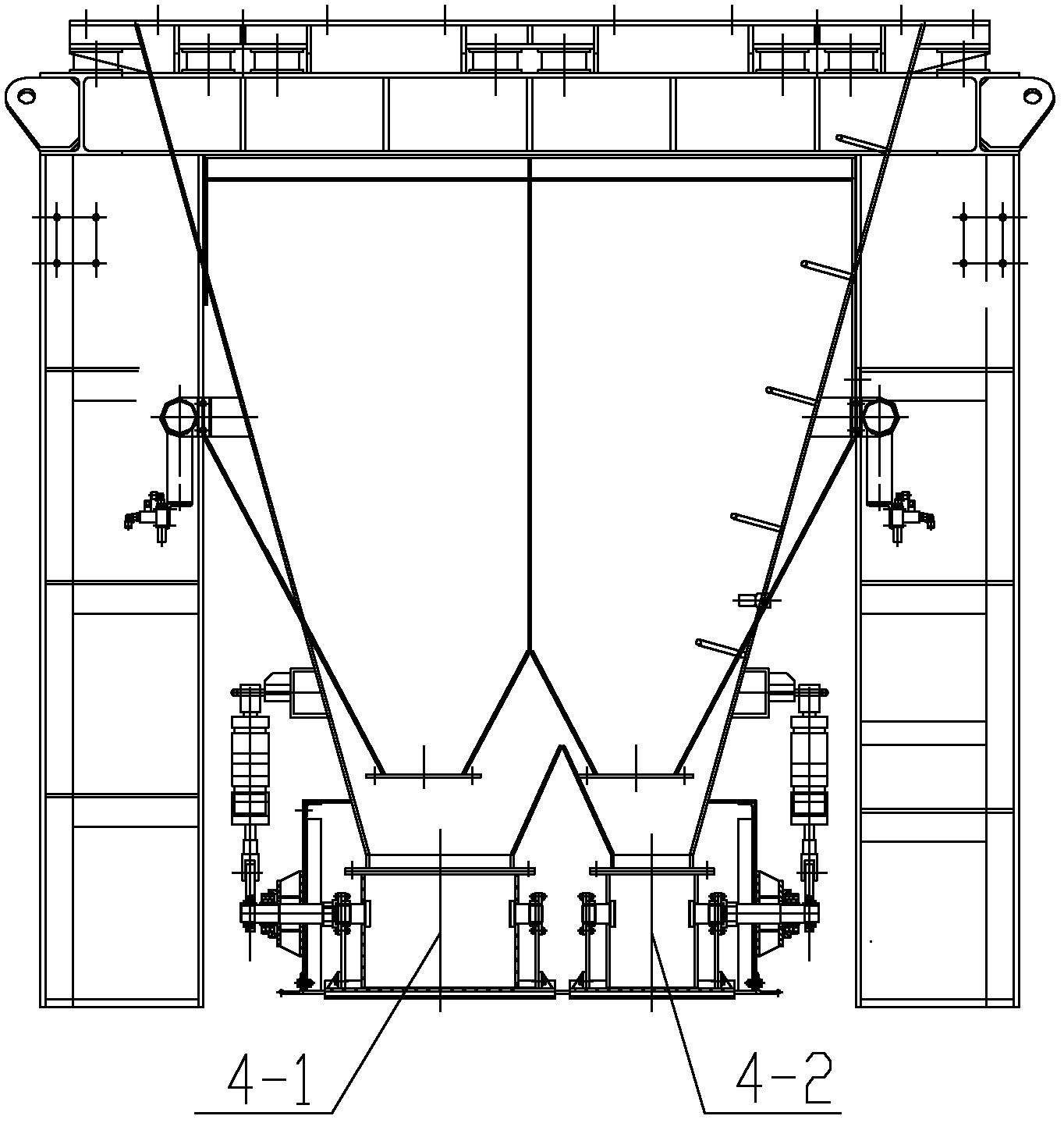

[0014] An aggregate batching door with adjustable opening, including a stone bin 1, a discharge door cylinder 2, a nylon sleeve 3 and a discharge door 4, the stone bin 1 is arranged above the discharge door 4; the stone bin 1 and the discharge door A discharging door cylinder 2 is arranged between the doors 4, and there are two discharging doors 4, namely a large discharging door 4-1 and a small discharging door 4-2; the diameter of the large discharging door 4-1 is larger than that of the small discharging door. The diameter of the material door 4-2; the cylinder 2 of the material discharge door is provided with a nylon sleeve 3.

Embodiment 2

[0016] An aggregate batching door with adjustable opening, including a stone bin 1, a discharge door cylinder 2, a nylon sleeve 3 and a discharge door 4, the stone bin 1 is arranged above the discharge door 4; the shape of the stone bin 1 is W shape; there is a discharge door cylinder 2 between the stone bin 1 and the discharge door 4, and there are two discharge doors 4, which are respectively the large discharge door 4-1 and the small discharge door 4-2; the large discharge door The diameter of the door 4-1 is greater than the diameter of the small discharge door 4-2; the cylinder 2 of the discharge door is provided with a nylon sleeve 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com