Mould structure of slender tubular product

A tubular and product technology, applied in the field of mold structure of slender tubular products, can solve the problems of unreliable positioning of the slender core of the rear mold, the product does not meet the technical requirements, and the product has eccentricity, etc. Reliable and ensure the effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

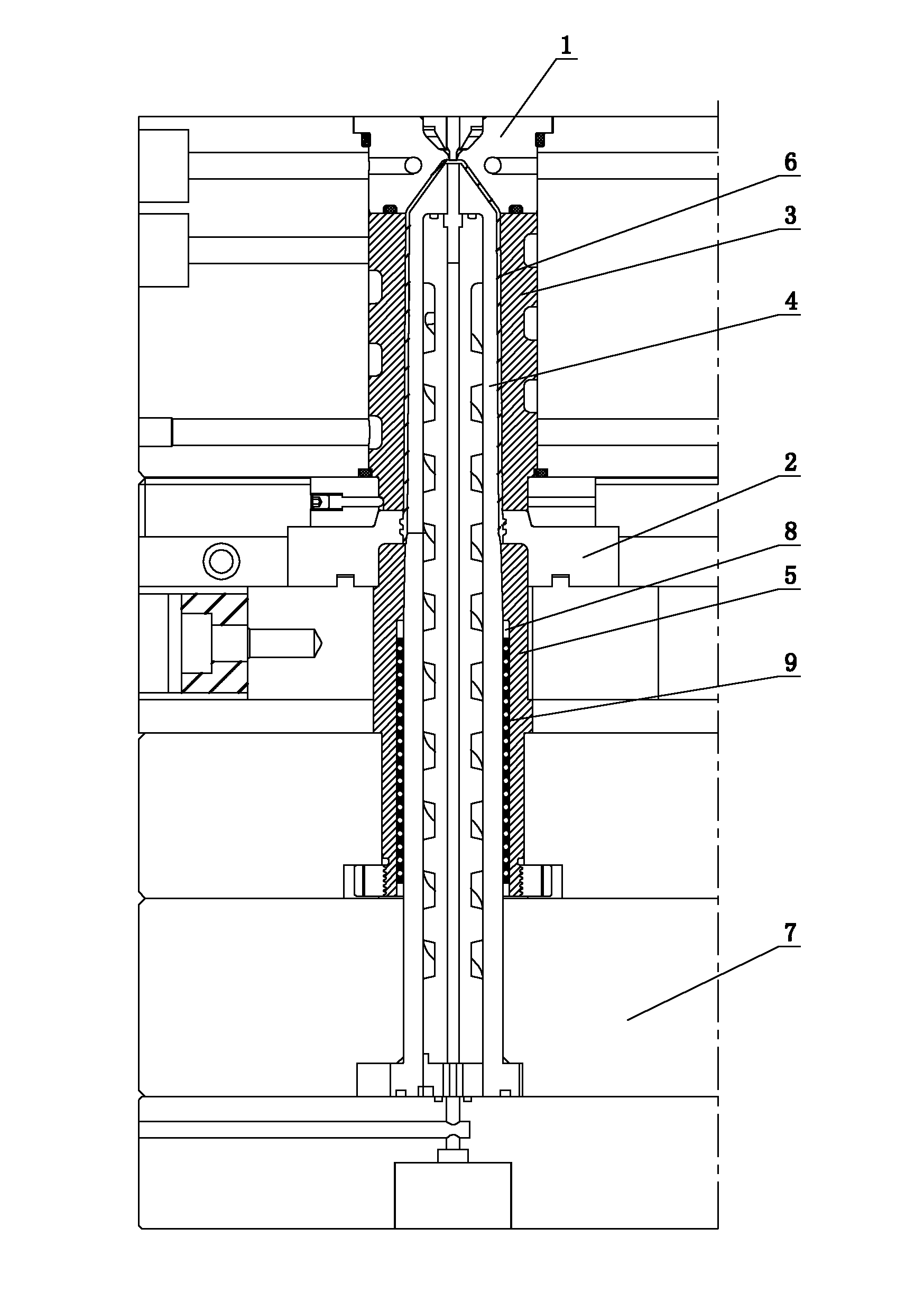

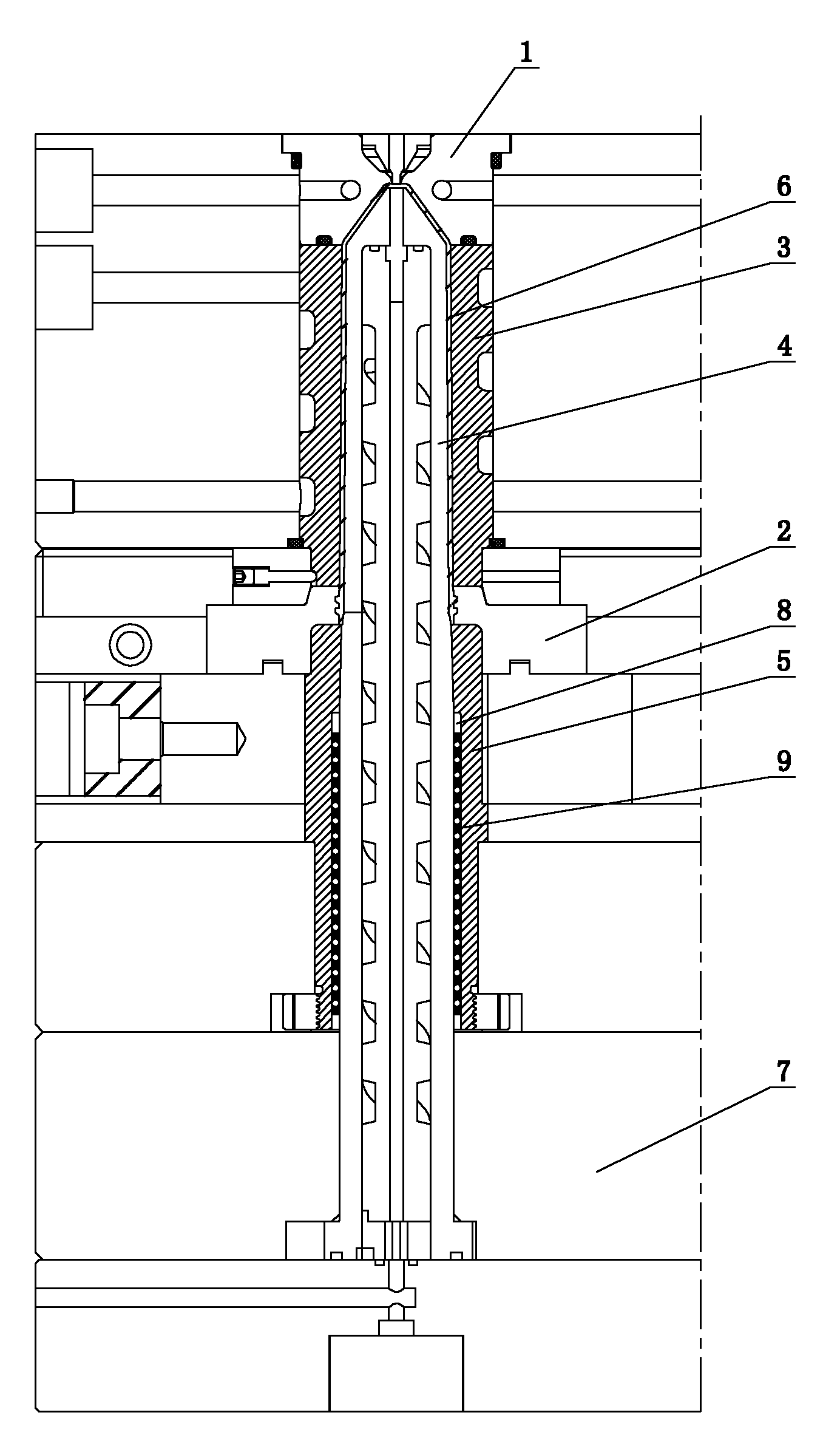

[0007] See figure 1 , which includes a front mold 1, a rear mold 2, a tubular outer circular core 3, a slender core 4, a fixed sleeve 5, a front mold 1, a rear mold 2, a tubular outer circular core 3, and a slender core 4. The cavity in the cavity is the mold cavity, and the product 6 to be formed is in the mold cavity, the fixed shaft sleeve 5 is set on the outer circular surface of the middle and lower part of the slender core 4, the bottom of the slender core 4 is fastened to the fixed plate 7, and the fixed shaft A steel ball bushing 9 is installed in the gap 8 of the sleeve 5 and the slender core 4, and the steel ball bushing 9 is set on the outer circular surface of the slender core 4, and the outer surface of the steel ball bushing 9 fits the fixed shaft sleeve 5. inner circle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com