Vehicle cavity separation member and application method thereof

A barrier and cavity technology, applied in the field of automotive cavity barrier, can solve the problems of insignificant vibration and noise reduction, poor versatility, etc., and achieve the effects of simple structure, not easy to deform, and favorable for foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

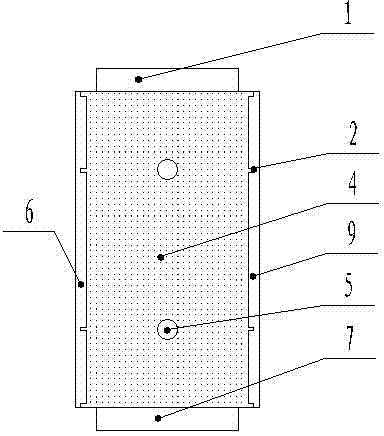

[0025] Embodiment 1: as figure 1 , figure 2As shown, a car cavity barrier includes a closed cuboid skeleton, the inside of which is hollow and evacuated. The frame is made of glass fiber reinforced nylon 66 with a mass fraction of glass fiber content of 25%. The front and rear surfaces of the frame are respectively provided with a reinforcement layer 4 and a vibration damping layer 8 . The reinforcing layer covers the entire front surface of the framework, and the vibration-damping layer covers the entire surface of the rear surface of the framework; the reinforcing layer is made of low-expansion epoxy resin material, with a thickness of 2mm; the vibration-damping layer is made of rubber-modified epoxy resin material, with a thickness of 1.5mm. There are two buckles 5 used to fix the cavity barrier on the reinforcement layer. The buckles are made of glass fiber reinforced nylon 66 with a glass fiber content of 25% by mass. The buckles penetrate the reinforcement layer and a...

Embodiment 2

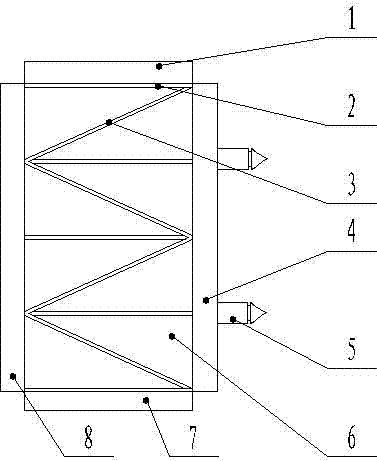

[0027] Embodiment 2: as image 3 , Figure 4 As shown, a car cavity barrier includes a closed cuboid skeleton, the inside of which is hollow and evacuated. The left and right surfaces of the skeleton are concave-convex surfaces with reinforcing ribs. The cross-section of the concave-convex surfaces is zigzag. After bending, a layer of unfoamed foam material is attached to the concave-convex surface. The concave-convex surface on the left surface of the skeleton is symmetrical to the concave-convex surface on the right surface, and the included angle between the inclined rectangular surface and the symmetrical plane of the concave-convex surfaces on the left and right surfaces of the skeleton is 20°. The uppermost inclined rectangular surface inclines from top to bottom toward the symmetrical plane away from the concave-convex surfaces on the left and right sides of the skeleton. The foam material layer includes the left foam layer 6 on the inclined rectangular surface of th...

Embodiment 3

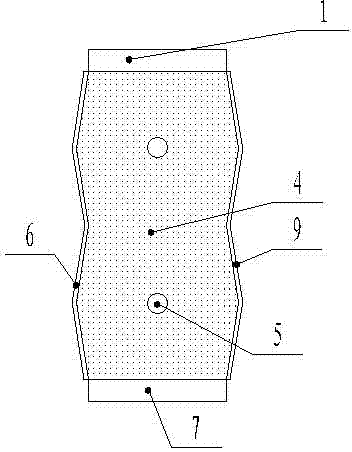

[0029] Embodiment 3: as Figure 5 , Image 6 As shown, a car cavity barrier includes a closed cuboid skeleton, the inside of which is hollow and evacuated. The left and right surfaces of the skeleton are concave-convex surfaces with reinforcing ribs. The concave-convex surface is composed of four connected rectangular units. The rectangular unit is composed of two triangular surfaces. The overlapping hypotenuses of the two triangular surfaces are convex or Concave inward (shown as convex outward in the figure), two adjacent rectangular units are distributed symmetrically along their connection line, the reinforcement includes oblique reinforcement and transverse reinforcement, and the oblique reinforcement is two triangular faces The bend at the coincidence of the hypotenuses, and the transverse reinforcement is the bend at the junction of two adjacent rectangular units. The concave-convex surface on the left surface of the skeleton is symmetrical to the concave-convex surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com