Vacuum processing apparatus

A vacuum treatment device and vacuum treatment technology, which is applied in the direction of transportation and packaging, conveyor objects, electrical components, etc., can solve the problem of increasing the degree of control of the conveying rate, the throughput is not controlled, and the conveying speed cannot meet the requirements of the vacuum side. Problems such as substrate handling and handling, to achieve the effect of suppressing time and suppressing footprint tracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

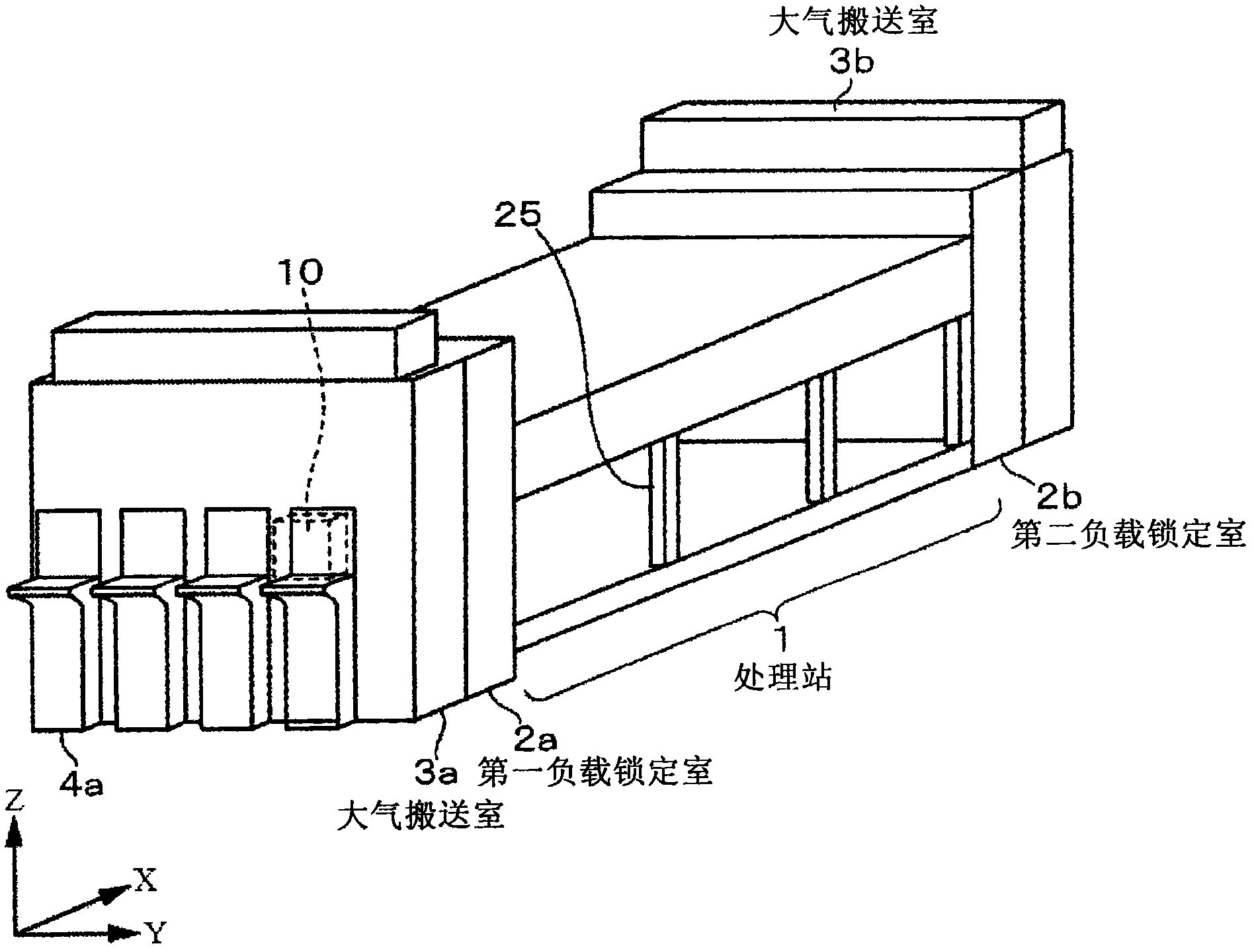

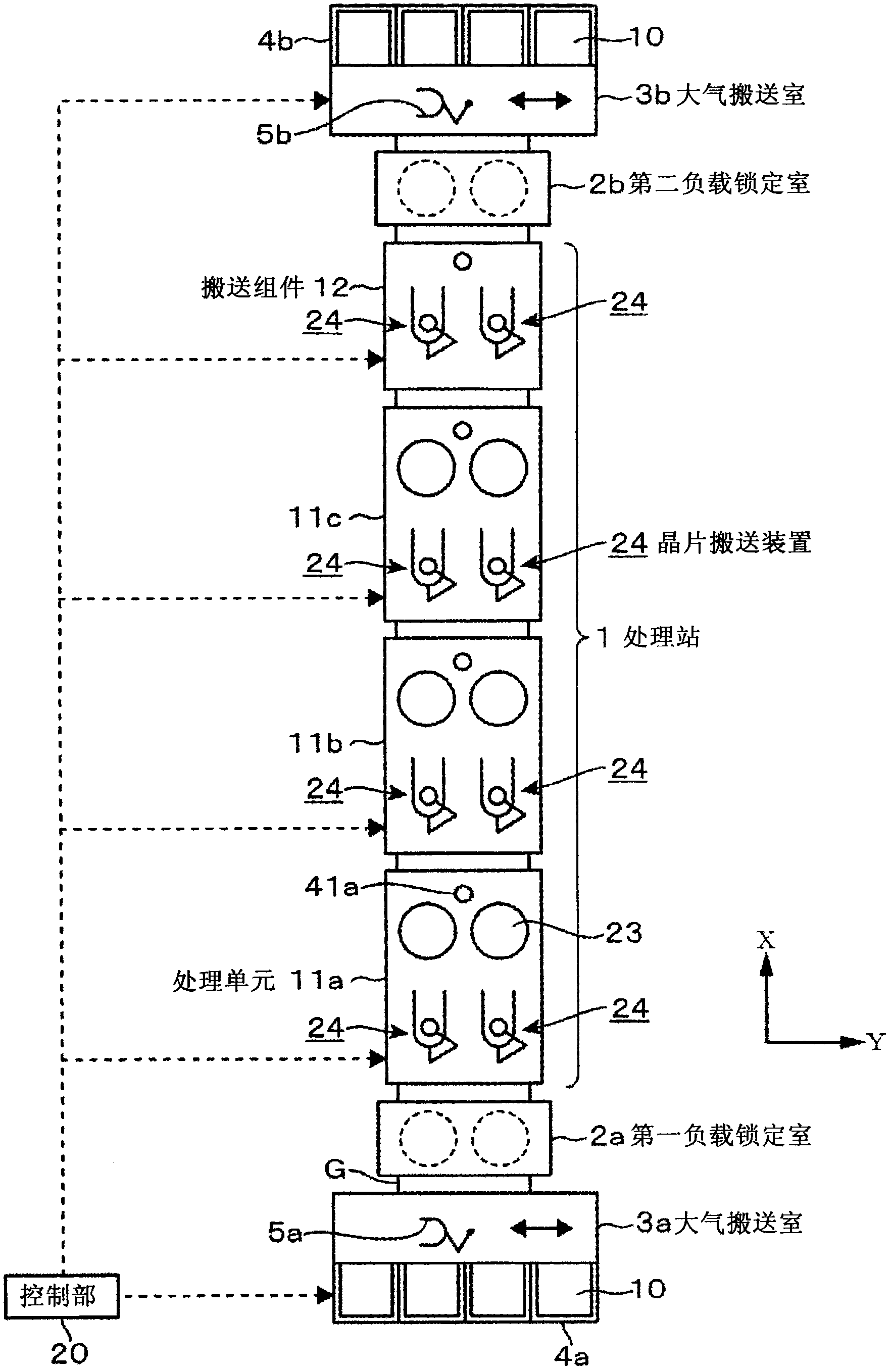

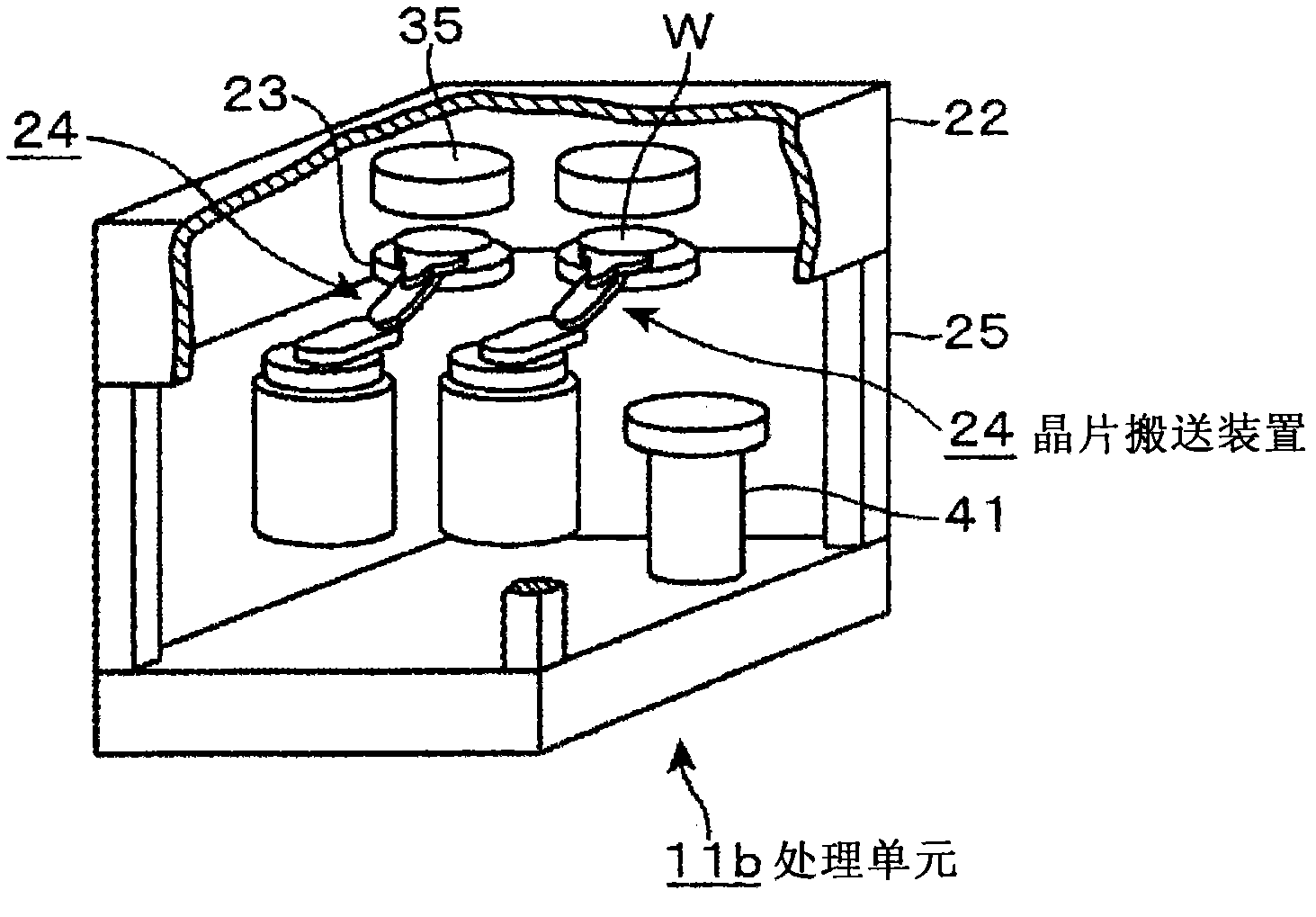

[0087] refer to Figure 1 to Figure 9 , an example of an embodiment of the vacuum processing apparatus of the present invention will be described. First, the overall structure of the vacuum processing apparatus will be described. The apparatus includes: a processing station 1 for processing a substrate, that is, a semiconductor wafer (hereinafter referred to as "wafer") W in a vacuum atmosphere. figure 1 and the first load-lock chamber 2a for carrying in and the second load-lock chamber 2b for carrying out, which are pre-vacuum chambers configured as follows: for opposing the processing station 1, respectively loading and unloading of the wafer W, with the processing station 1’s figure 2 One end side on the front side of the center and the other end side on the back side are respectively airtightly connected, and the internal atmosphere is switched between an atmospheric atmosphere and a vacuum atmosphere.

[0088] These load lock chambers 2a, 2b are configured so that two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com