Atmospheric plasma device and manufacturing method thereof

An atmospheric pressure plasma and plasma technology, applied in the direction of plasma, electrical components, etc., can solve the problems of difficulty in removing, reducing the life of the device, corrosion of the cathode insulating medium, etc., and achieve the effect of improving cleaning uniformity, improving life, and reducing corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

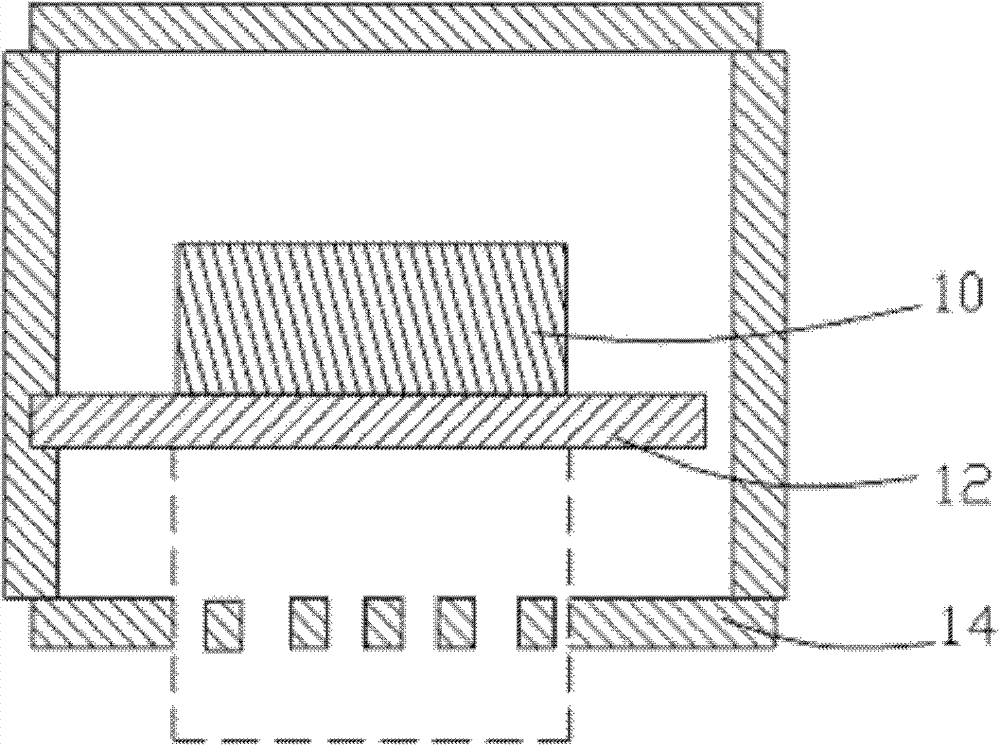

[0030] refer to figure 2 , and see in conjunction with image 3 , is a structural schematic diagram of the first embodiment of the atmospheric pressure plasma device of the present invention, the atmospheric pressure plasma device includes: an anode 10, an insulating medium 12 and a cathode 14, the cathode 14 refers to the part facing the anode 10 with the insulating medium 12 separated, and the positive The partial area of the pair is equal to the area of the anode 10 .

[0031] The insulating medium 12 is disposed between the anode 10 and the cathode 14 .

[0032] An ionizable gas is filled between the anode 10 and the cathode 14 .

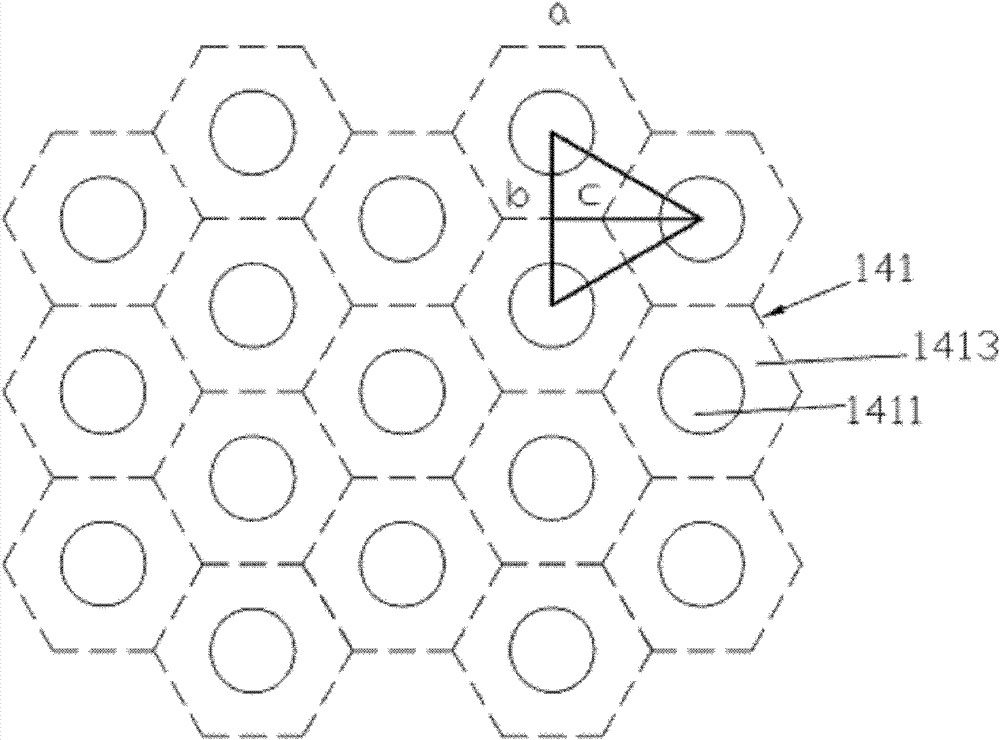

[0033]The cathode 14 includes a plurality of uniformly distributed identical plasma generation and removal units 141 . The above-mentioned plasma generation and exclusion unit 141 naming is determined for conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com