Fixture used in combination of circular seams of cylinder

A tooling and girth seam technology is applied in the field of tooling in which the cylinder body girth seam is paired, which can solve the problems of heavy workload of workers and unsightly appearance of products, and achieves a large working range, saves appearance time, and saves the amount of misalignment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

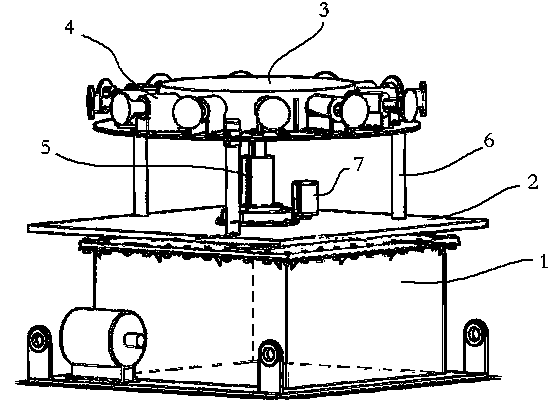

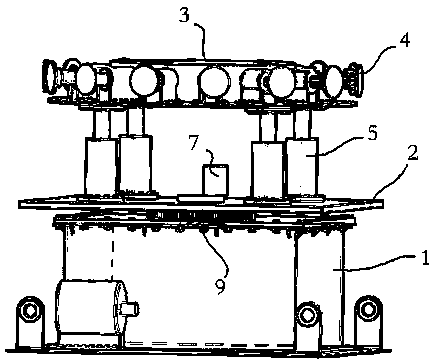

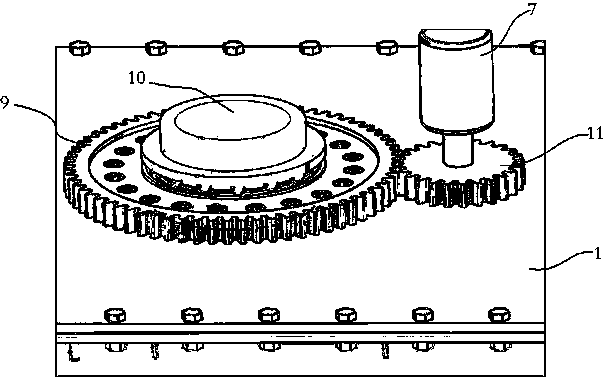

[0022] Specific embodiment 1 of the present invention, as figure 1 As shown in the figure, a tooling for cylinder ring seam assembly includes a frame 1, an oil tank for the entire hydraulic system of the tooling can be installed inside the frame 1, and a vertical rotating shaft 10 is installed on the frame 1, such as image 3 As shown, a horizontally arranged working platform 2 is installed on the rotating shaft 10. The working platform 2 is driven by a main driving device and can rotate around a vertical rotating shaft. The main driving device includes a motor 7 installed on the working platform 2 , a pinion 11 is installed on the rotating shaft of the motor, the pinion 11 is located on the underside of the working platform 2, and meshes with the large gear 9 fixed on the frame 1, as figure 2 , image 3 and Figure 4 shown. A lifting device is installed on the working platform 2. The lifting device in this example is an oil cylinder 5 installed on the working platform 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com