Dump truck and bottom plates thereof

A technology of dump truck and bottom plate, which is applied in the direction of tilt-bearing moving vehicles, etc., can solve the problems of not being able to unload cleanly at one time, the impact of the lifting cylinder, and the overturning accident, so as to increase the buffer, improve the unloading efficiency, and improve the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

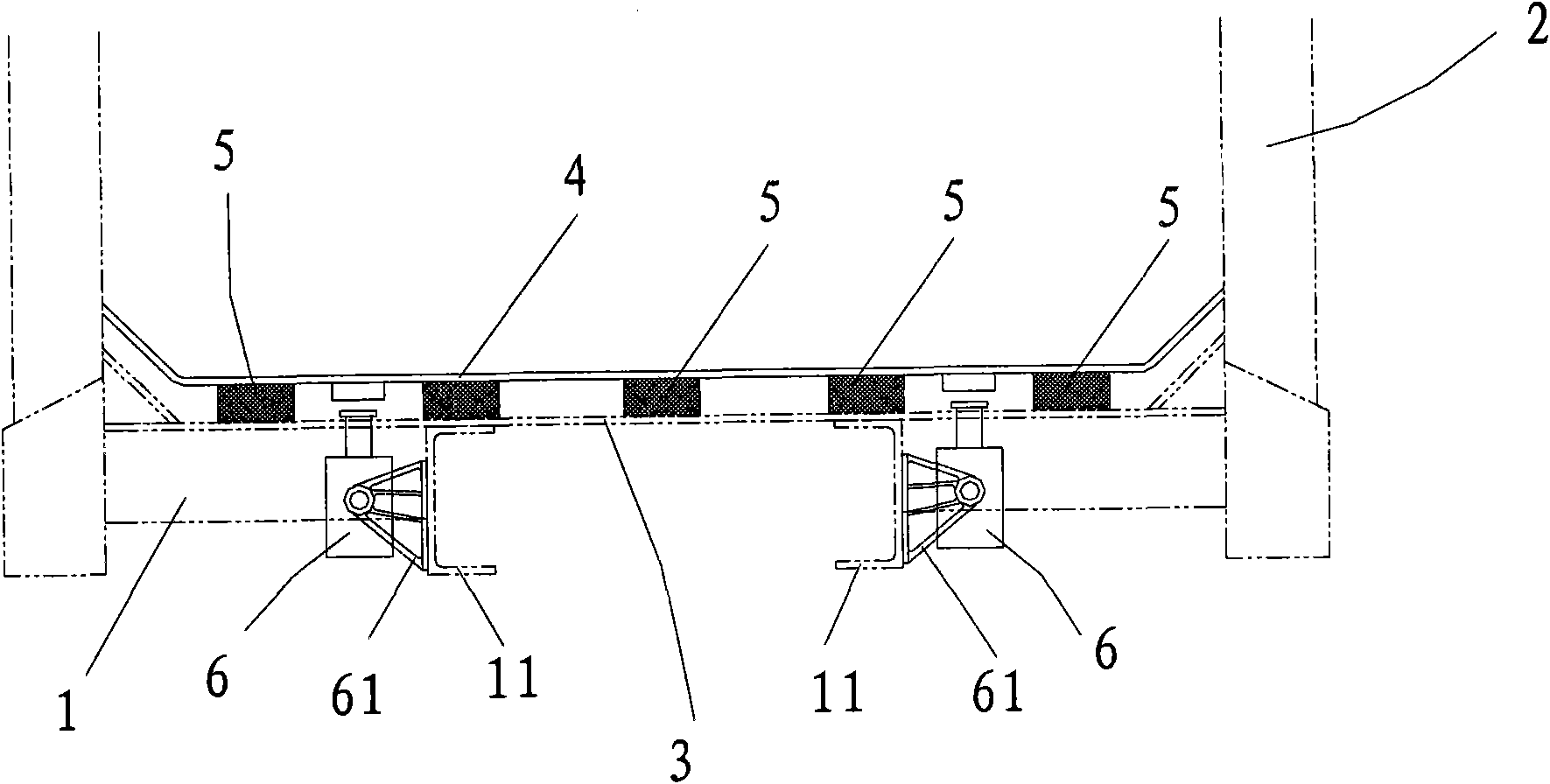

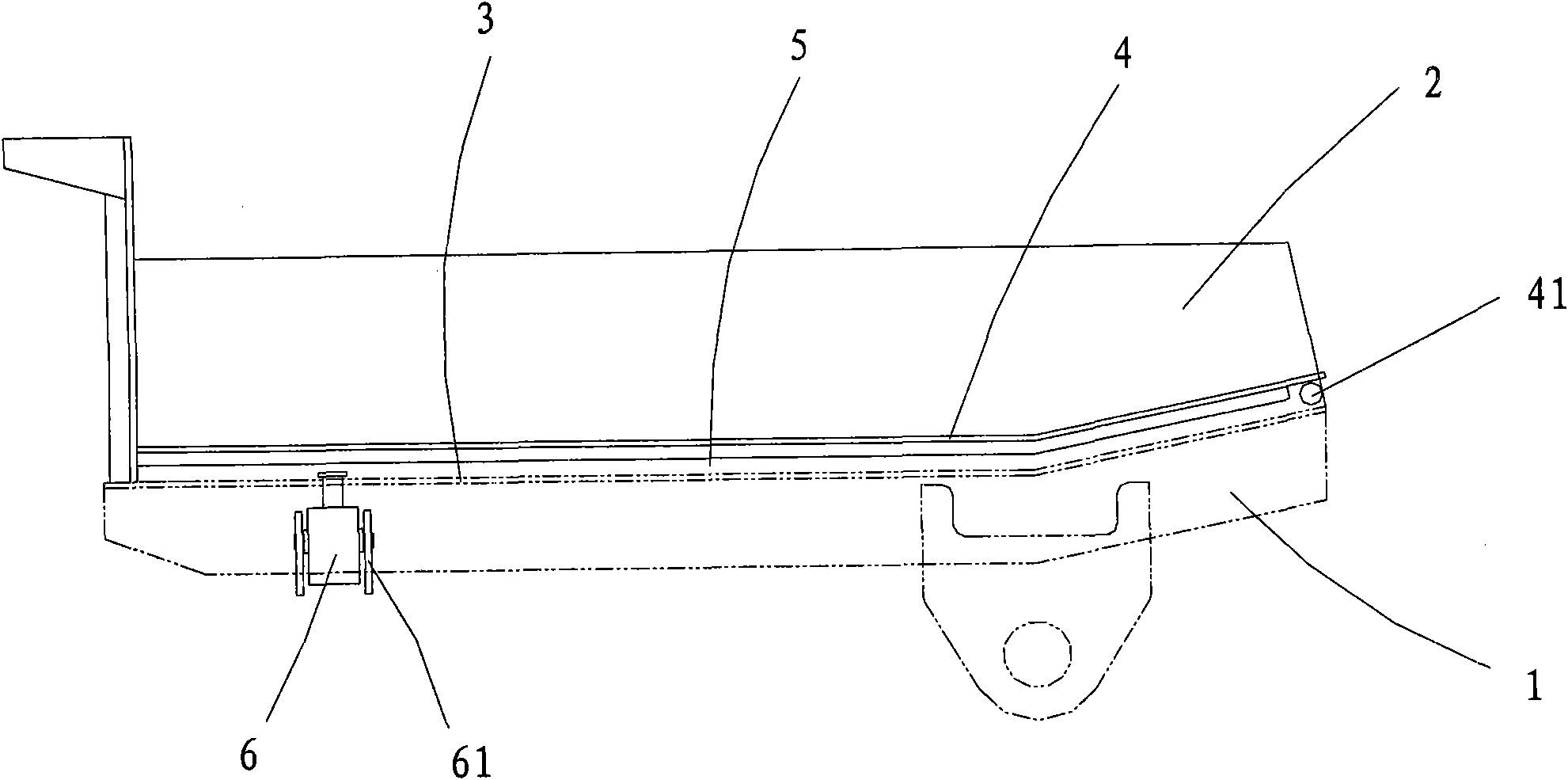

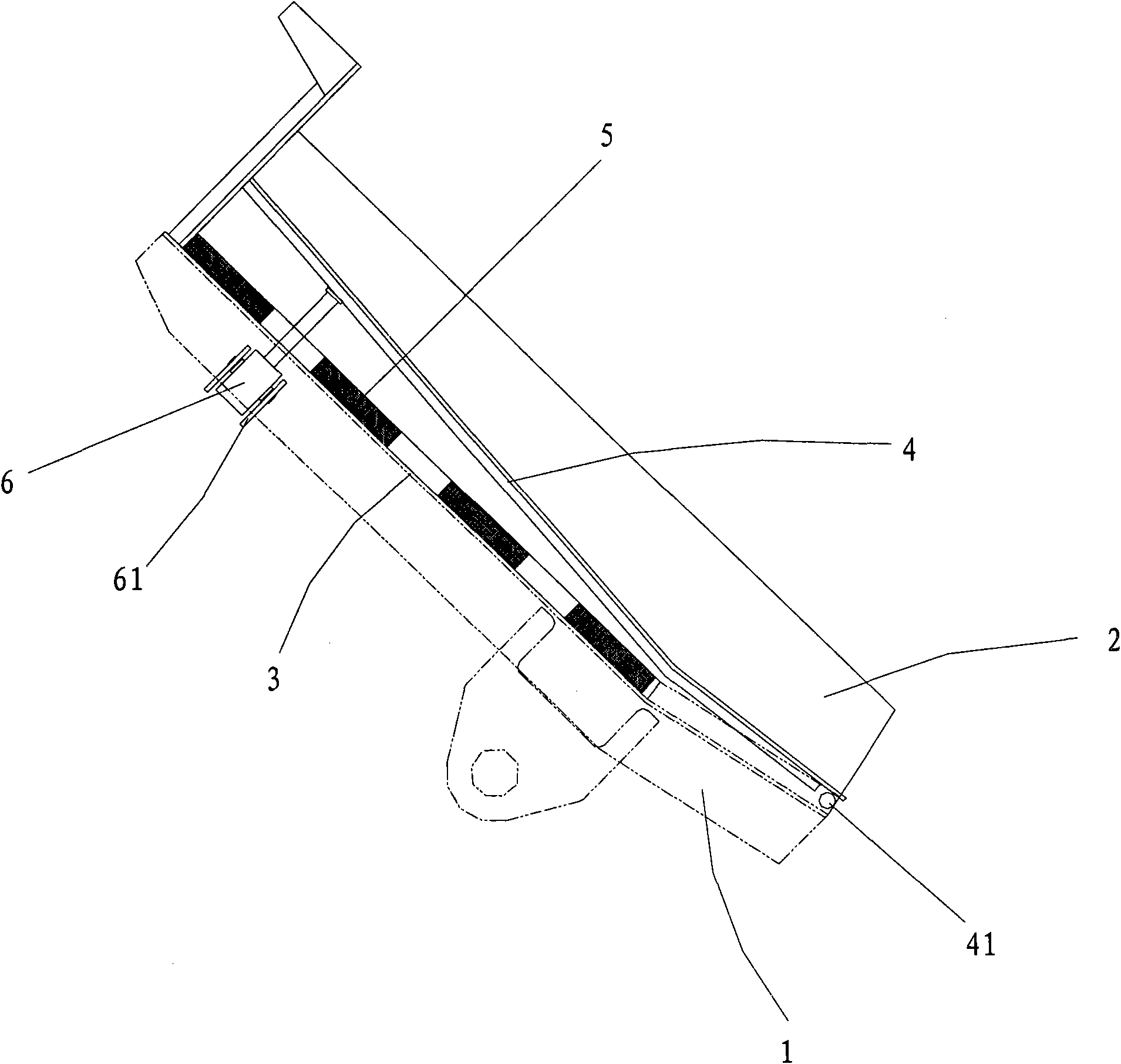

[0022] refer to Figure 1-Figure 2 , The dump truck includes: an underframe 1, a running mechanism (not shown) arranged below the underframe, a compartment 2 arranged above the underframe 1 and a cab (not shown) arranged at the front end of the underframe 1 . A first bottom plate 3 and a second bottom plate 4 are installed on the bottom frame 1, the rear portion of the first bottom plate 3 is hinged with the rear portion of the bottom frame 1, and the bottom of the first bottom plate 3 front portion is provided with the first bottom plate 3. jacking cylinder (not shown). This second base plate 4 is installed on the top of the first base plate 3, and the rear portion of the second base plate 4 is hinged with the first base plate 3 by a hinge shaft 41, and the bottom of the second base plate 4 front is provided with two driving second base plates 4 away from Or the auxiliary oil cylinder 6 close to the first bottom plate 3 . The first bottom plate 3 is provided with through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com