Friction pendulum type shock absorption and isolation support seat

A vibration isolation and pendulum technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of complex bearing structure, bearing damage and damage, weak lateral stiffness, etc., achieving obvious frictional energy consumption, long service life, good reset function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

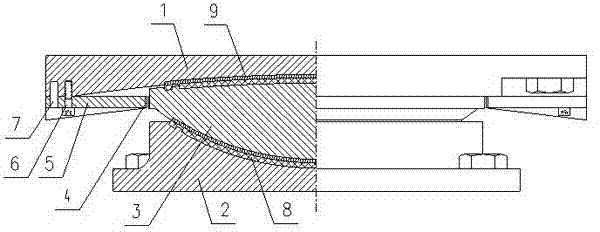

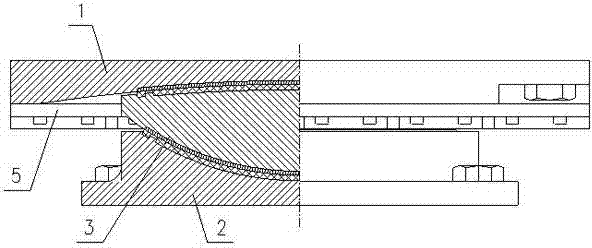

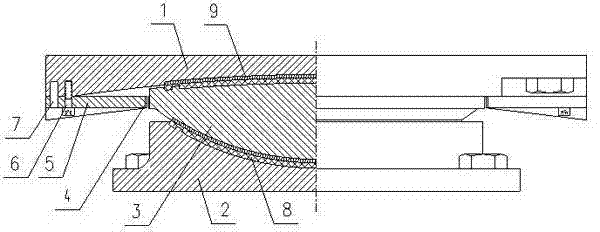

[0023] Such as figure 1 and figure 2 As shown, a friction pendulum type shock-absorbing and isolation support includes an upper seat plate 1, a lower seat plate 2, a double spherical rotating block 3 and a limit block 5, and the double spherical rotating block 3 is arranged on the upper and lower seat plates 1, 2 Between them, in the direction of the cross bridge, the lower surfaces of the left and right ends of the seat plate 1 are respectively fixed with the limit block 5 by the pin 7 and the limit block bolt 6, and one end of the limit block 5 is in contact with the side of the double spherical rotating block 3, and the double spherical surface rotating block 3 is in contact with each other. The upper and lower surfaces of the spherical rotating block 3 are spherical surfaces, and the lower surface of the upper seat plate 1 and the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com