High-pressure inflating pump structure

A technology of air pumps and high-pressure gas cylinders, which is applied in the direction of liquid displacement machines, machines/engines, mechanical equipment, etc. It can solve the problems of high manufacturing costs, bending deformation damage of puncture parts 45, and low surface accuracy, so as to save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

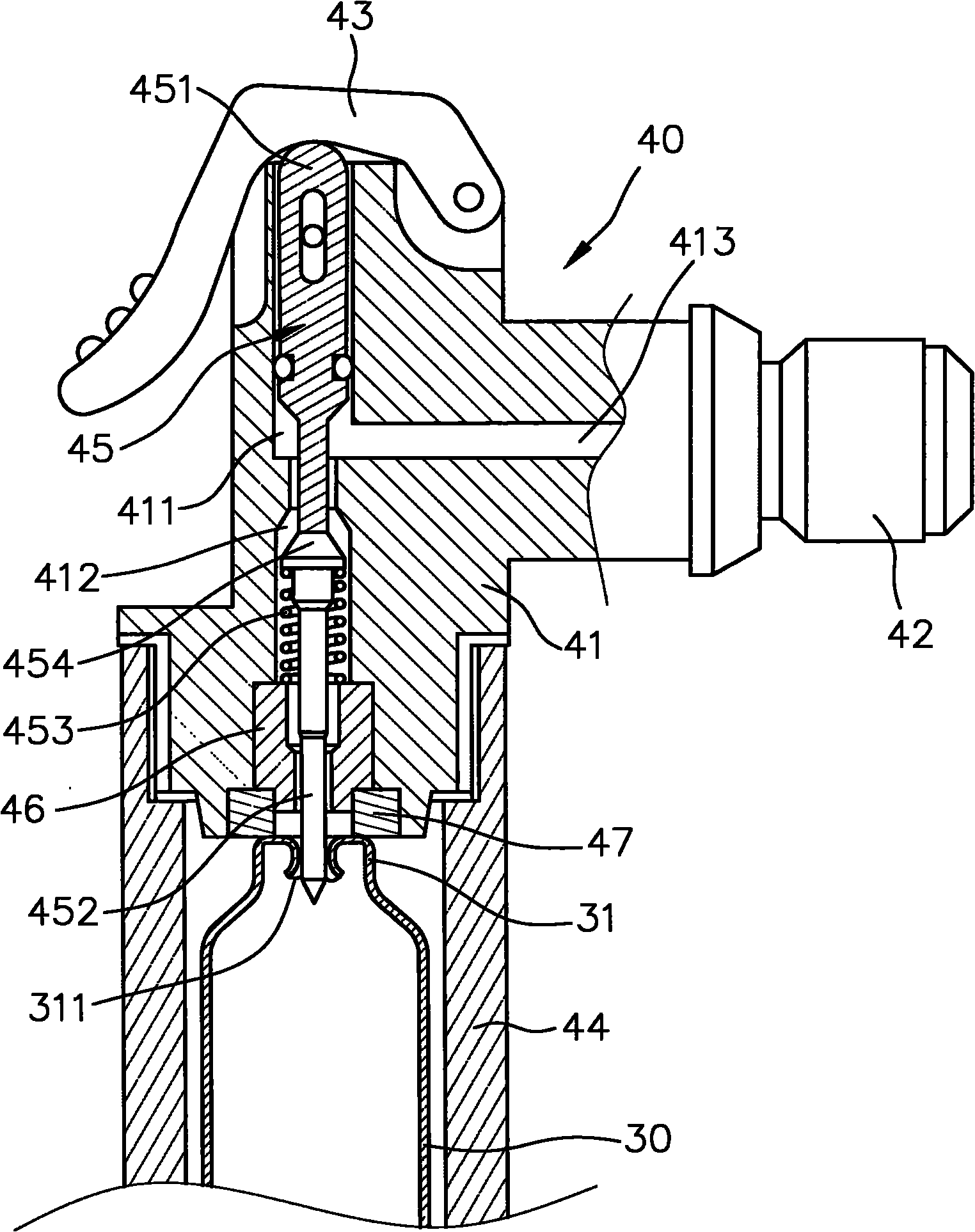

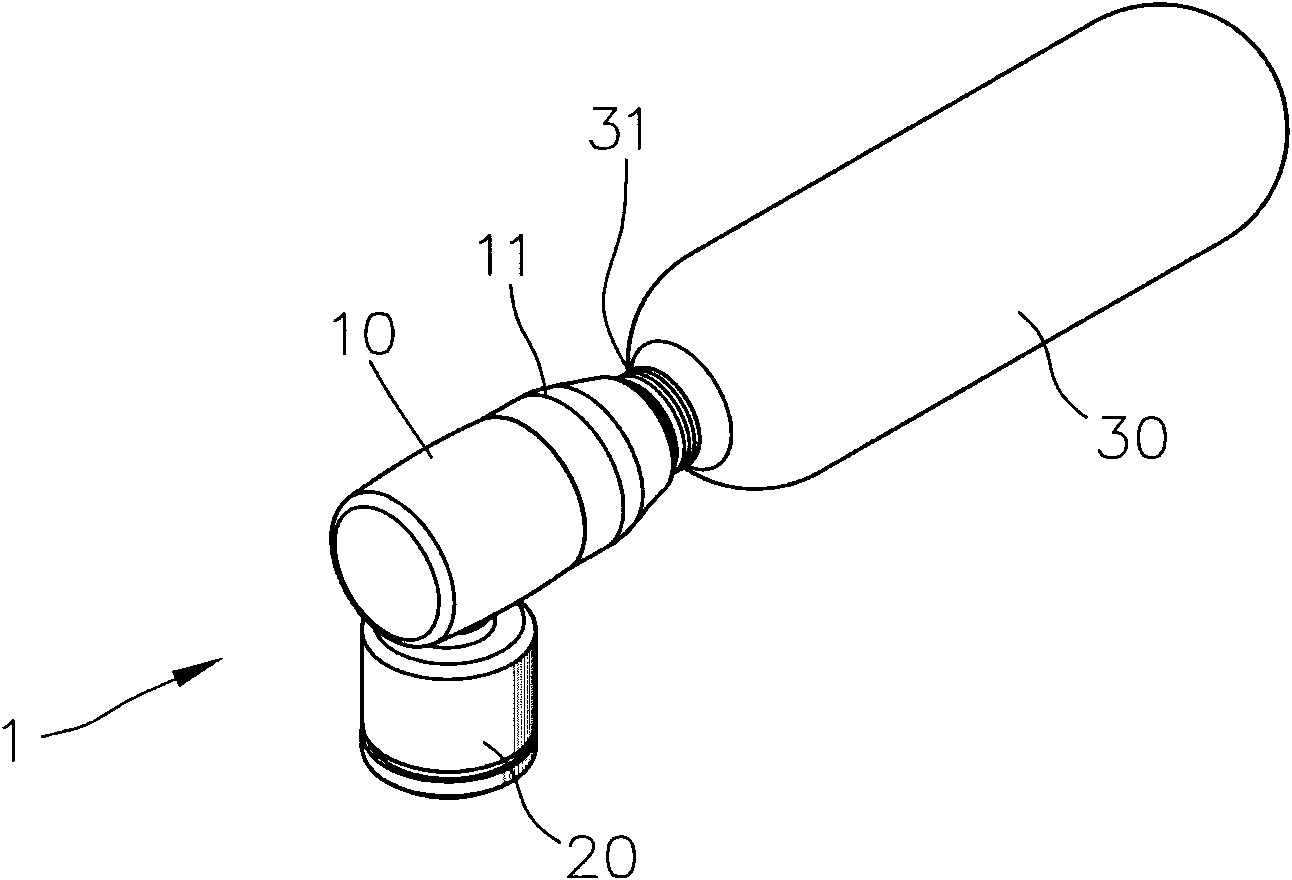

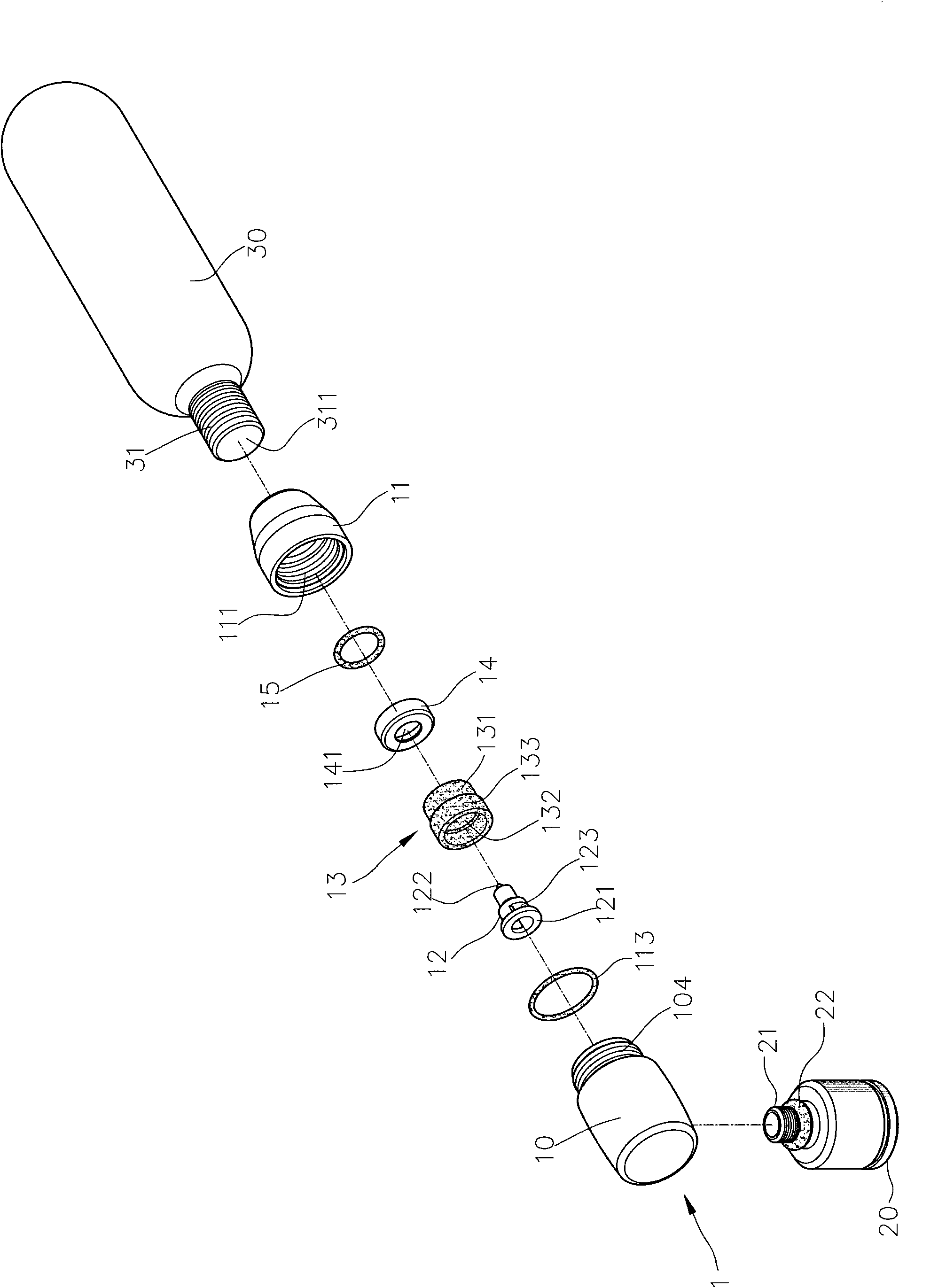

[0049] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0050] see figure 2 , image 3 and Figure 4 The structural design of the preferred embodiment of the present invention shown is to solve the problem that the structure of the known CO2 inflator is too complicated, and to effectively maintain the air pressure in the high-pressure gas cylinder 30 such as the CO2 gas cylinder for multiple inflation actions, and to strengthen the The durability of the structure, the high-pressure pump structure of the present invention takes a head 1 as the main body, wherein the head 1 has a first cylinder 10 and a second cylinder 11, and the first cylinder 10 and the second cylinder 11 The opposite ends are provided with threaded parts 104, 111 which can be screwed relative to each other, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com