High-temperature gas circulating fan

A technology for circulating fans and gas, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems affecting the sealing effect of mechanical seals and the effect of fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

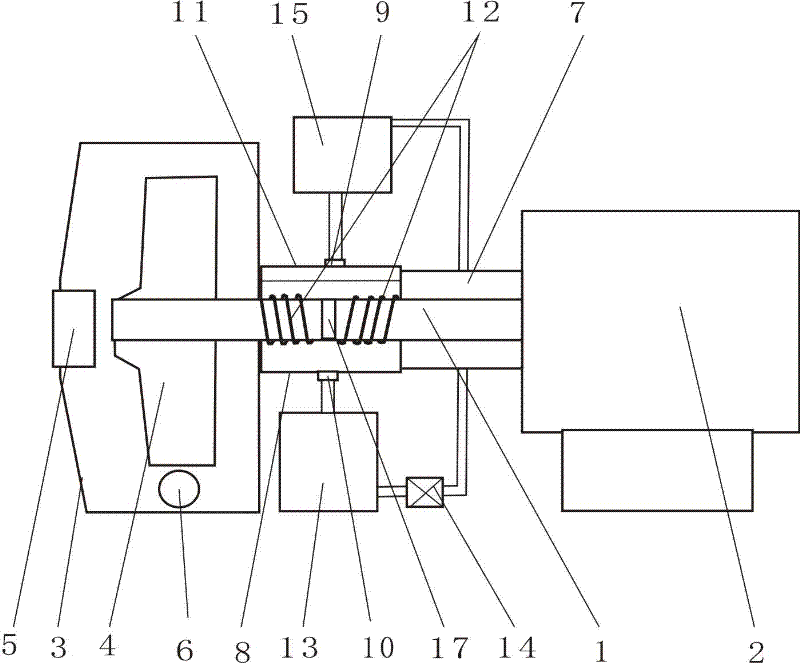

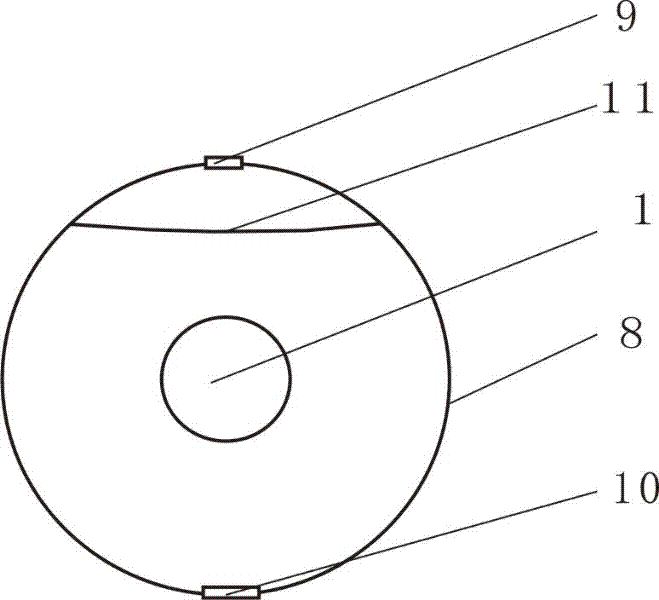

[0016] Such as figure 1 Shown, the high-temperature gas circulation blower of the present invention, it comprises main shaft 1, driving device 2, air pressure device and sealing device, and described air pressure device comprises casing 3, the impeller 4 in casing 3, and described casing 3 is provided with air inlet 5, air outlet 6. One end of the main shaft 1 is in transmission connection with the output shaft of the driving device 1 , and the other end is in transmission connection with the impeller 4 of the wind pressure device. The sealing device is outside the main shaft 1 between the driving device 1 and the wind pressure device, and the sealing device includes a mechanical sealing body 7 arranged outside the main shaft 1, and the mechanical sealing body 7 can adopt some structures of the existing fan industry , such as the labyrinth seal, because the sealing device has little correlation with the main innovation points of the high-temperature gas circulation fan of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com