Spring absorber and vibration-resistant sulfur hexafluoride gas density relay

A technology of sulfur hexafluoride gas and spring shock absorbers, which is applied in the field of spring shock absorbers, can solve the problems that spring shock absorbers cannot be applied, affect the safe operation of the power grid, and cannot guarantee the reliable and safe operation of sulfur hexafluoride electrical products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

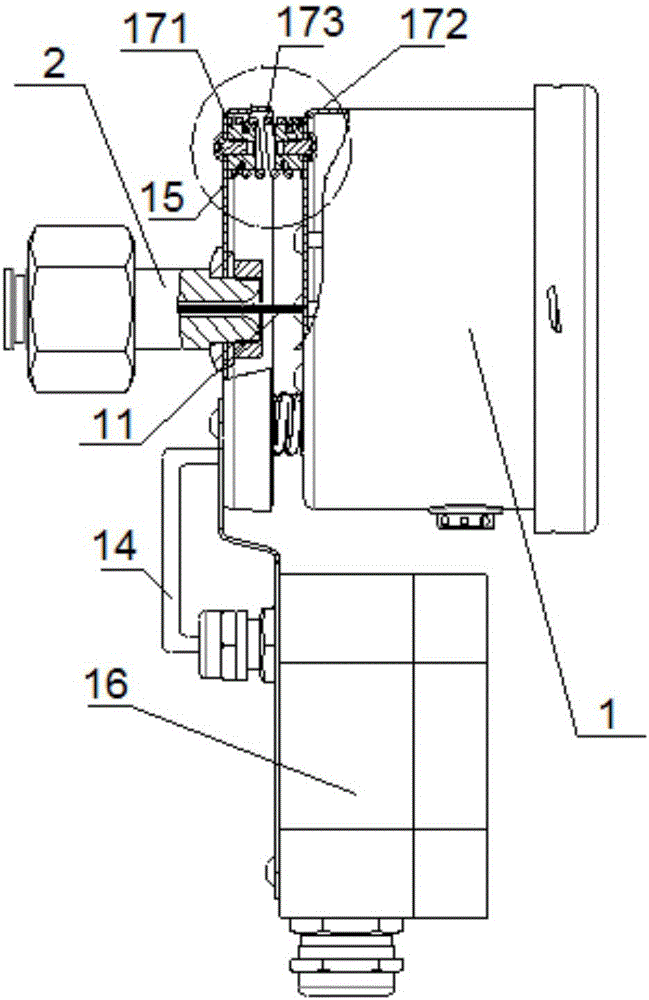

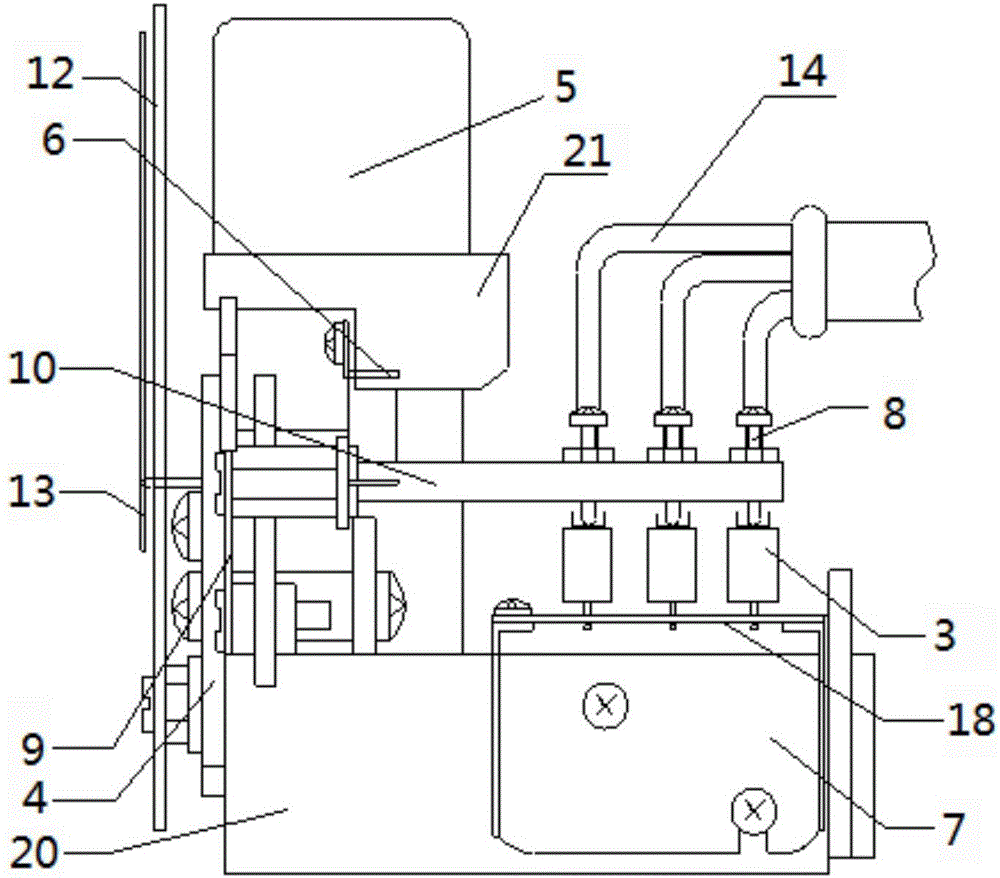

[0065] See Figure 1 to Figure 3 And combine Figure 4 , The present invention, namely the anti-vibration type sulfur hexafluoride gas density relay, includes a relay case 1, a joint 2, and the relay case 1 includes a signal generator 3, a movement 4, a pressure sensing element 5, a temperature compensation element 6, The fixed plate 7 corresponds to the adjusting rod 8, the connecting rod 9, the beam 10, and the pipe 11 of the signal generator 3. There are also a dial 12, a pointer 13, and a printed board 18 in the housing 1. The pointer 13 is fixed on the movement 4 , The dial 12 is fixed on the movement 4, one end of the pressure-sensitive element 5 is welded to the base 20 communicating with the joint 2 in the gas path, and the other end is welded to the end seat 21, and the end seat 21 is connected to the temperature compensation element 6 In this embodiment, the signal generator 3 is a micro switch, or a magnetic-assisted electrical contact, and the photosensitive element...

Embodiment 2

[0078] Such as Figure 5 Shown and combined Image 6 , An anti-vibration type sulfur hexafluoride gas density relay of the present invention, the outer shape joint is a radial structure. Since the joint 2 is fixed on the chassis 15, the closest effective distance between the lower side of the chassis 15 and the lower side of the shell is represented by H, and H is greater than 2.3mm. When the joint 2 vibrates, the vibration is transmitted through the spring damper 17. To the shell 1, at this time, when the vibration is caused by the outside, the vibration affected by the joint 2 is first transmitted to the chassis 15, and the chassis 15 is transmitted to the spring shock absorber 17, and the spring shock absorber 17 undergoes buffering and vibration absorption, and then greatly It alleviates the vibration that affects the shell. In this way, the shock absorber greatly alleviates the vibration that affects the shell. At the same time, since the closest effective distance between ...

Embodiment 3

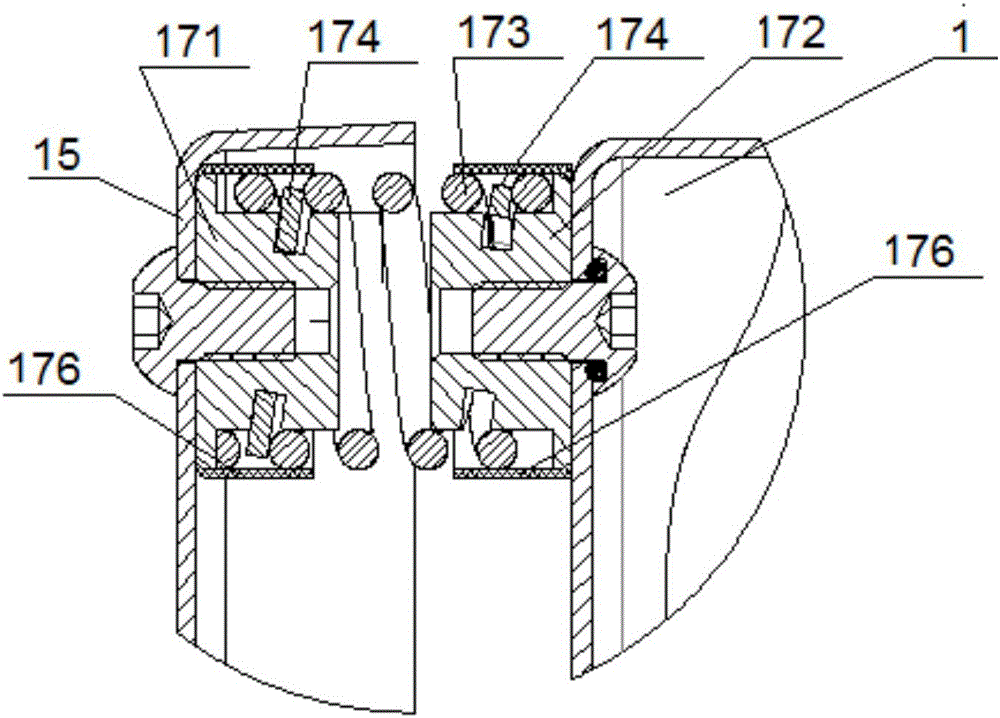

[0080] Such as Figure 7 As shown, the spring damper of an anti-vibration type sulfur hexafluoride gas density relay of the present invention includes two fixing seats 171, 172 and a spring 173, and the fixing seats 171, 172 are There is a groove, the groove is a thread shape, and the groove on the fixing seat is a T-shaped thread. One end of the spring 173 is installed in the groove 177 of one fixing seat 171, and the other end of the spring 173 is installed in the groove 177 of the other fixing seat 172. The two fixing seats have a proper gap to allow the spring to compress or extend.

[0081] The fixing base 171 includes a fixing base body 1711 and a limiting portion 1712. The fixing base body 1711 is cylindrical, and the groove 177 is provided on the outside of the fixing base body 1711. The limiting portion 1712 is the One end of the fixing base body 1711 extends outward. The fixing seat 172 includes a fixing seat body 1721 and a limiting portion 1722. The fixing seat body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com