Method for designing straw gasification gas boiler

A technology of gas boiler and design method, applied in the field of gas boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

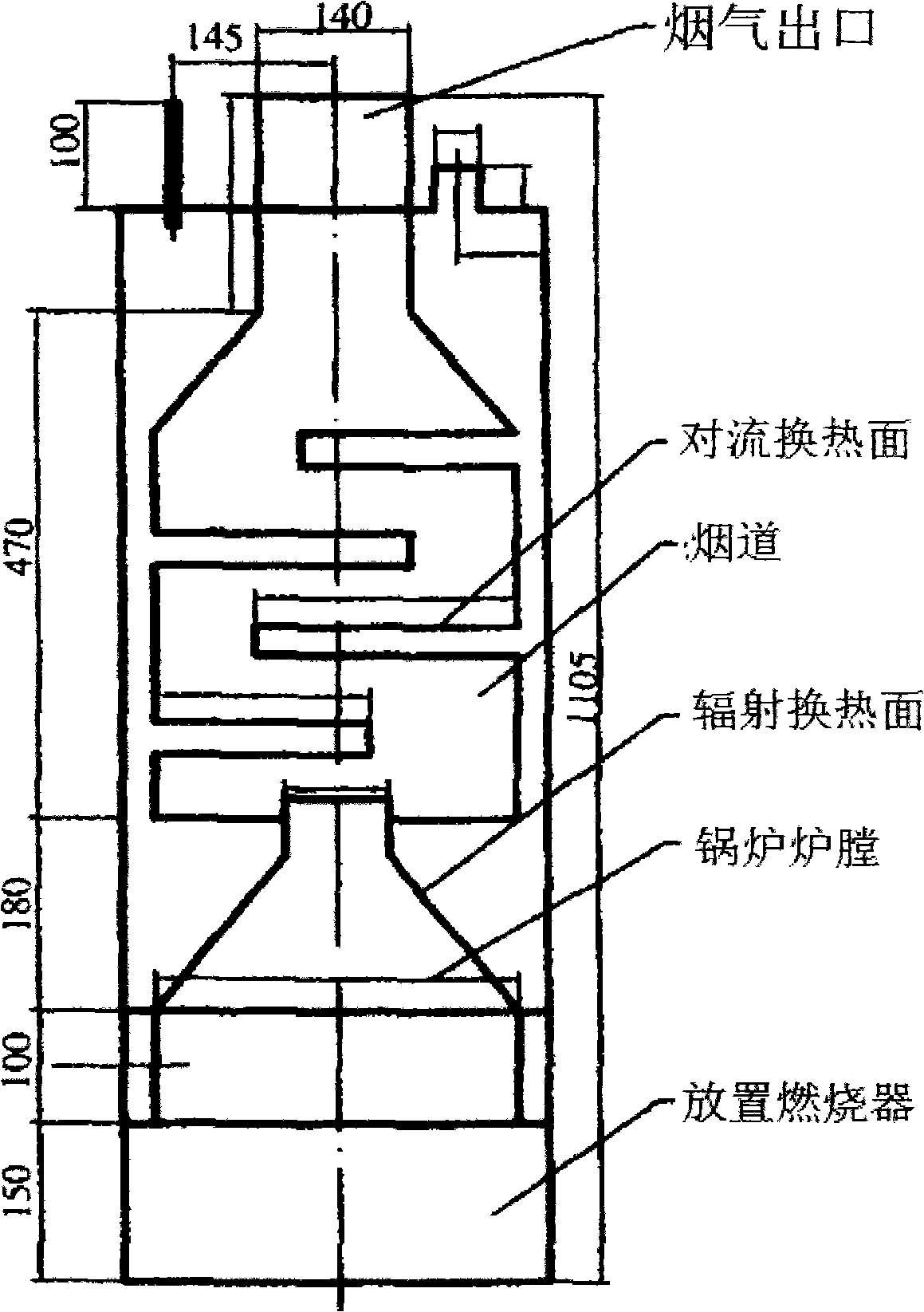

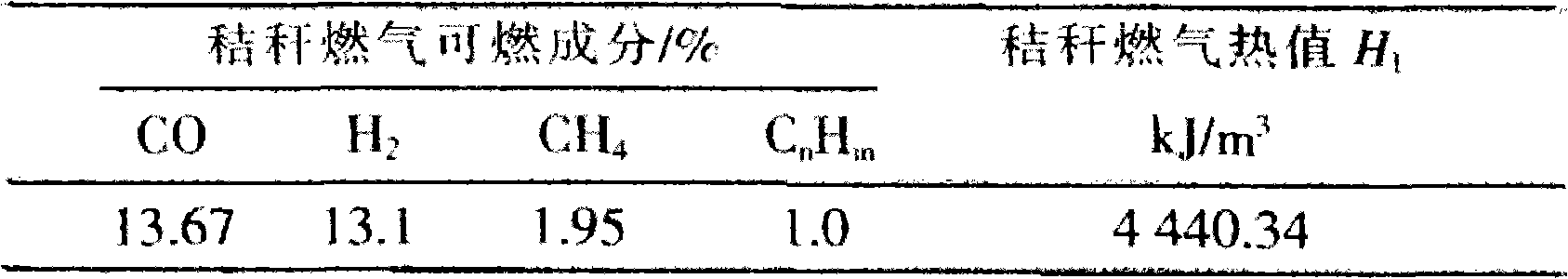

[0019] This example provides a design method for a straw gasification gas-fired boiler, taking the northern rural heating area as 50m2 2 Taking the housing as an example, the design of the straw gasification gas boiler is carried out:

[0020] 1. Calculation of heat load of heating boiler

[0021] The design heat load of the house is the basis for determining the heat load of the heating boiler. Due to the great difference in the form of farmer houses, this design adopts the area heat index method to estimate the heat load of the house heating design. Select the heating heat index q per unit area f 81.5W / m 2 , the heating area F of the farmer’s house is 50m 2 , the design heat load Q of farmer’s house is

[0022] Q=q f F=81.5x50=4075W

[0023] Since the heating time of farmers is generally about 8 hours per day, the effective heat load Q of boiler heating g for

[0024] Q g =Qx(24 / 8)=12225W

[0025] The thermal efficiency of the heating boiler is 60%, and the nomina...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap