Lubricant dispenser

A technology of lubricants and distributors, which is used in lubricating parts, engine lubrication, signal processing, etc., can solve the problem of unsatisfactory environmental costs, increasingly complex electronic control of lubricant distributors, and inability to guarantee lubricant distributors, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

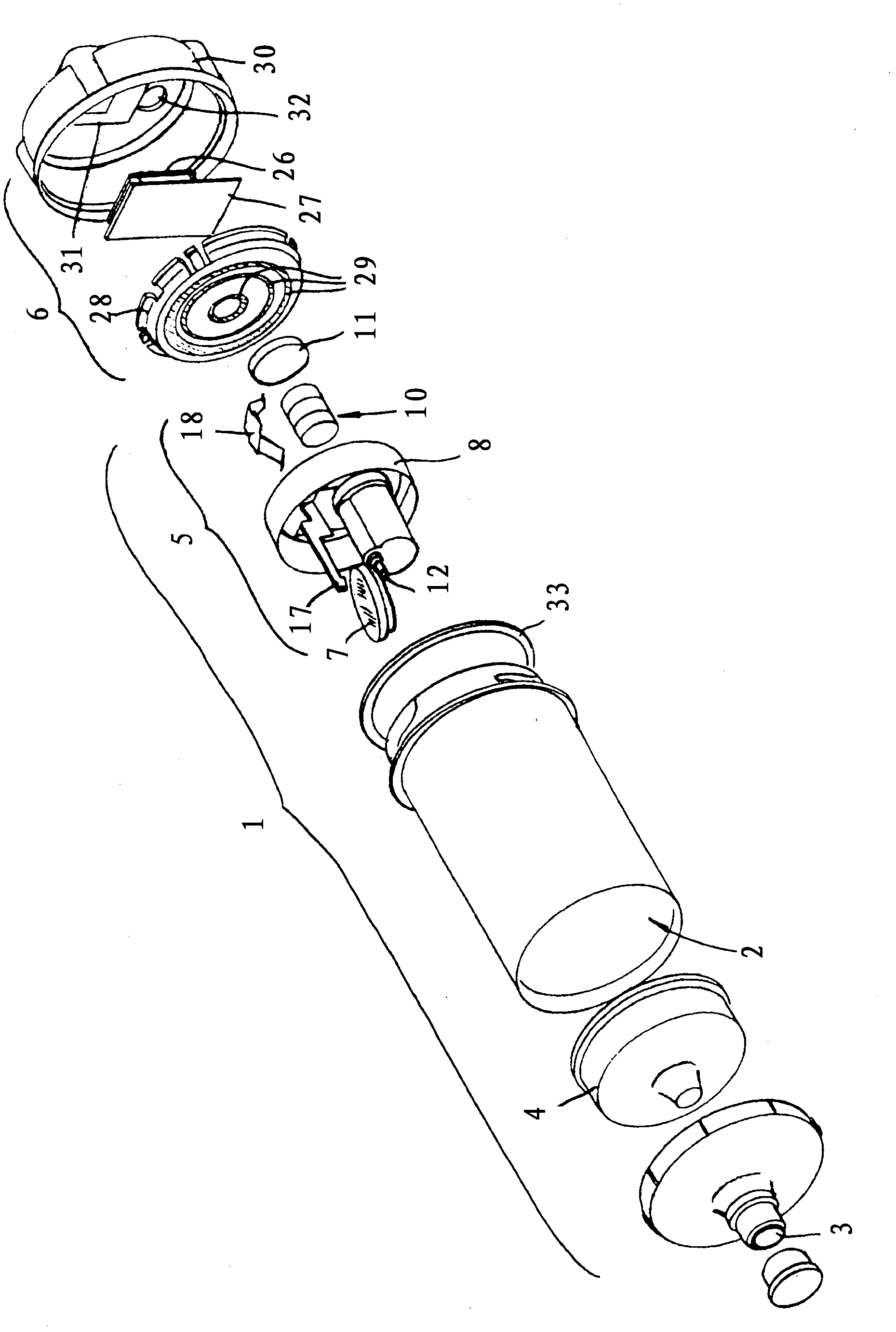

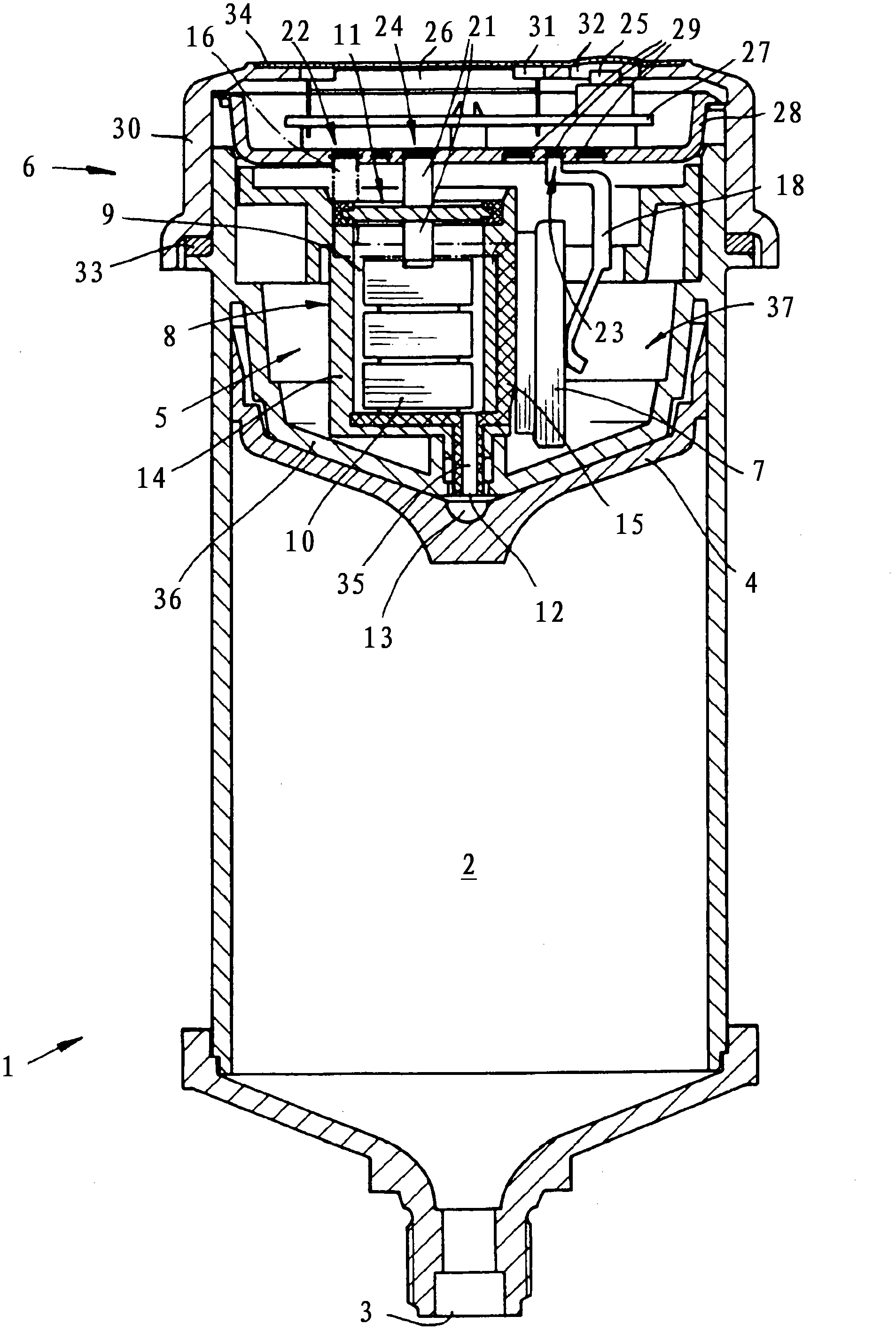

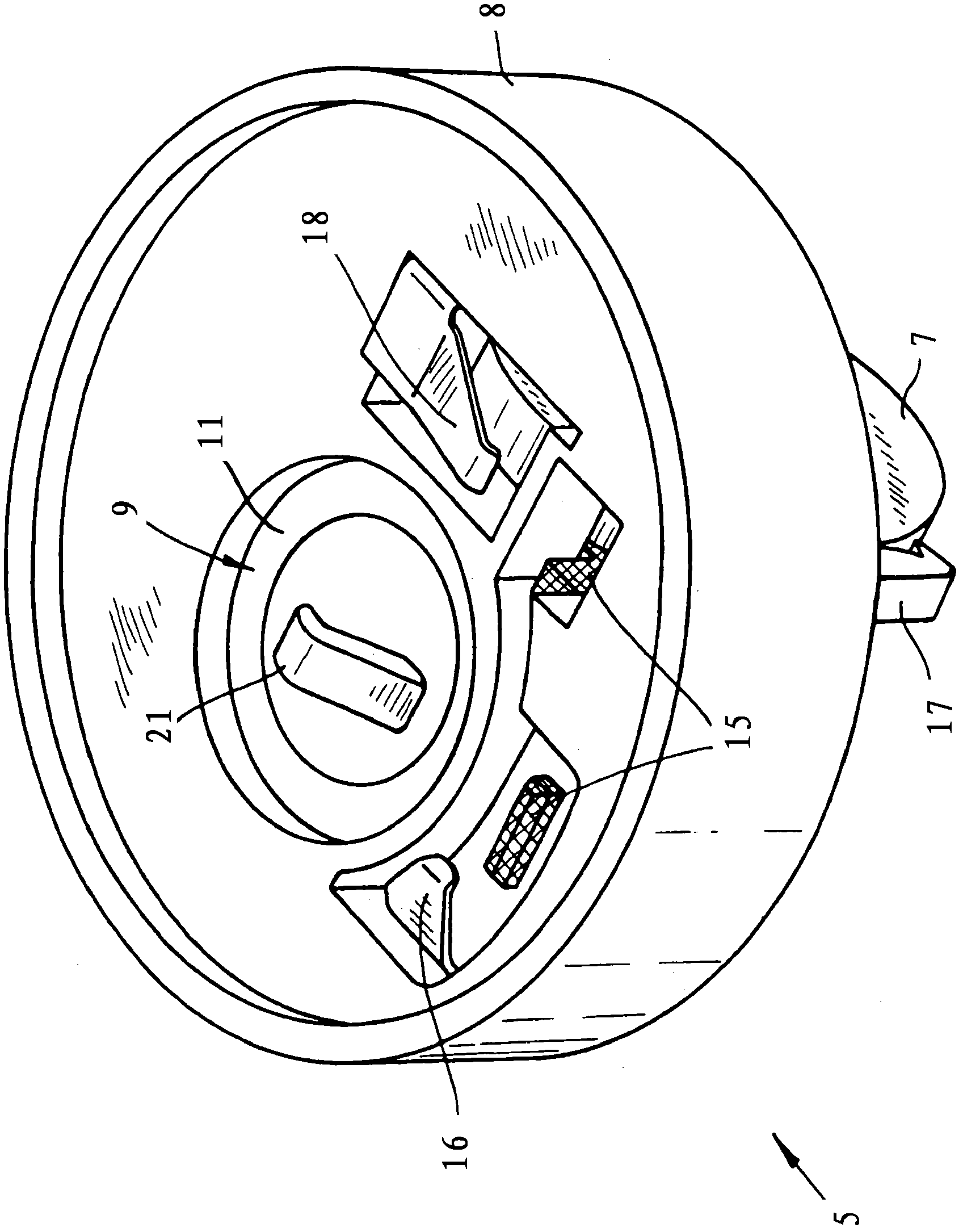

[0017] The basic structure of the lubricant dispenser shown in the drawings includes a lubricant cartridge 1 , an electronic control unit 6 for controlling electrochemical gas generation, and a drive battery 7 for powering the electronic control unit 6 . The lubricant cartridge 1 comprises a lubricant reservoir 2 provided with a lubricant outlet 3 , a piston 4 and a gas generator unit 5 for electrochemical gas generation. The electronic control unit 6 is detachably connected to the lubricant cartridge 1 as a separate and reusable unit and has electrical contact elements which are in connection with the electrical terminals of the gas generator unit 5 . The drive battery 7 is fastened inaccessibly on the support 8 of the gas generator unit 5 . The electronic control unit 6 does not have its own power supply, so only by mounting the electronic control unit 6 on the lubricant cartridge 1 is the electrical circuit assigned to the gas generator unit 5 closed and the electronic cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com