Automatic taping machine

A hemming machine, automatic technology, applied in the direction of machining/deformation, etc., can solve the problems of strong limitations of the machine, difficult to remove quickly, etc., to achieve the effect of wide application, easy troubleshooting, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

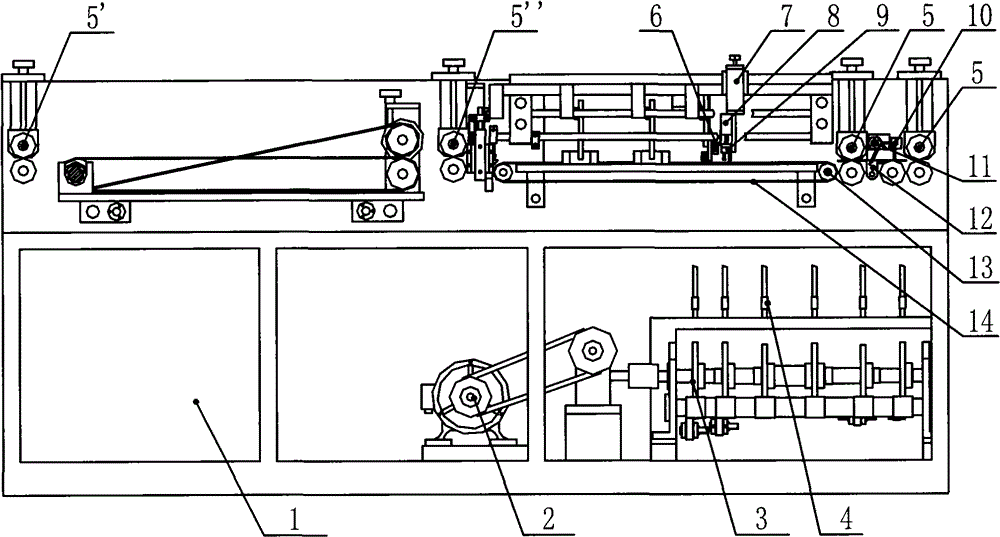

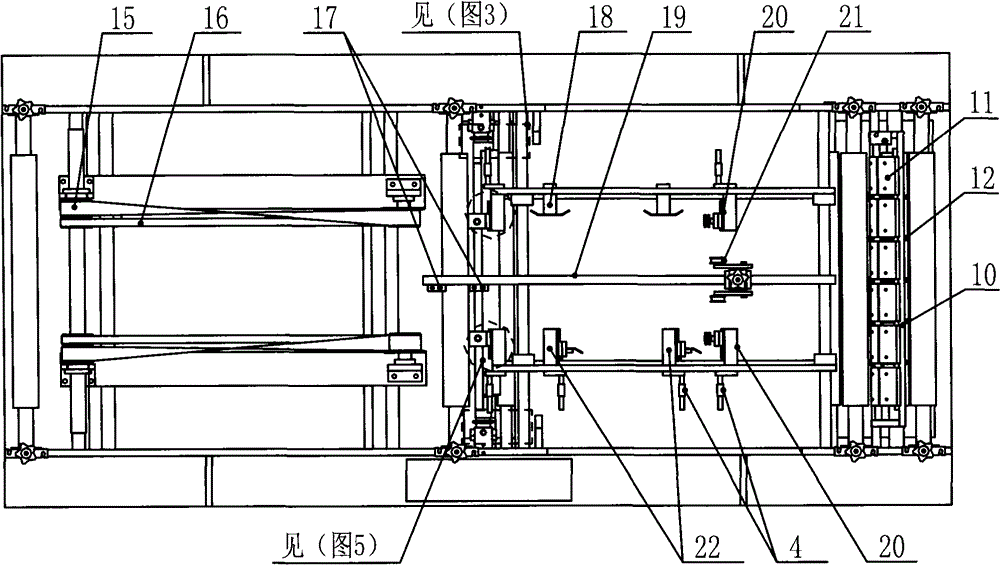

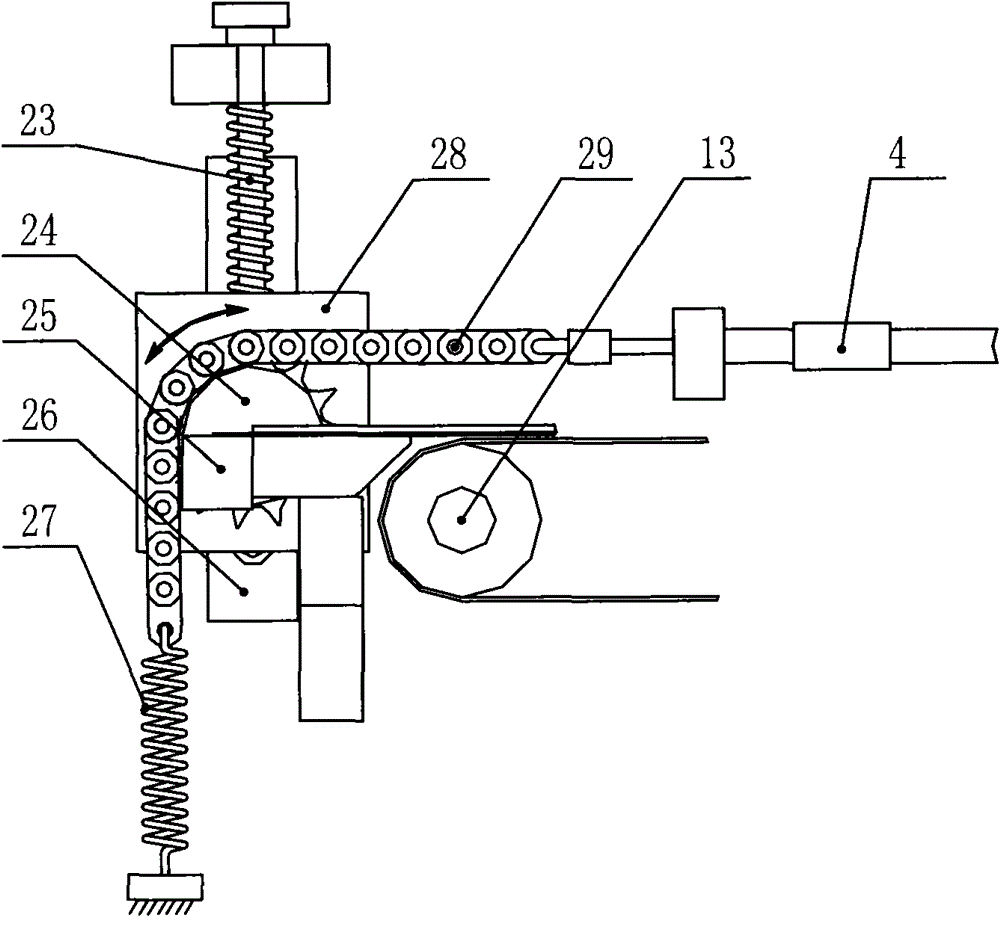

[0031] Next, the automatic hemming machine of the present invention will be described in detail below with reference to the accompanying drawings.

[0032] The automatic hemming machine of the present invention has a structure comprising a frame 1, a main power device 2, a baffle plate, a front hemming device, a front cornering mechanism, and a rear cornering mechanism 20; the main power device is arranged below the frame, the The main power unit is connected with the front hemming device, the front cornering mechanism and the rear cornering mechanism 20 provided with the frame through the cam transmission mechanism 3 and the transmission flexible shaft 4 .

[0033] A baffle is arranged directly behind the front hemming device and the front cornering mechanism on the frame, and the baffle is divided into a cardboard baffle 9 and movable baffles 22 set on the left and right sides of the baffle cylinder guide rail 19 , fixed baffle plate 18, described movable baffle plate, fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com