Closed structure consisting of composite material

A closed structure, composite material technology, applied in aircraft parts, household components, household appliances, etc., can solve problems such as difficulty in designing Ω-shaped sections of longitudinal beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

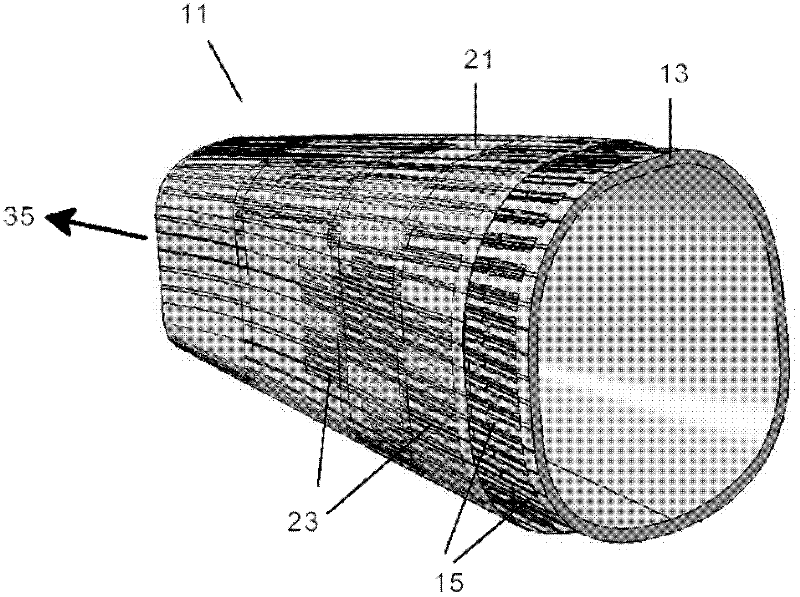

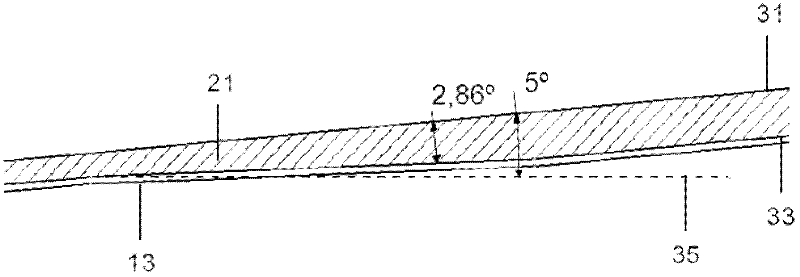

[0016] The invention disclosed below relates to a component 11 of an aircraft fuselage made of composite material as a single integral piece. figure 1 The part 11 is shown in the process of being demolded from the clamp 13 according to the demolding direction 35 .

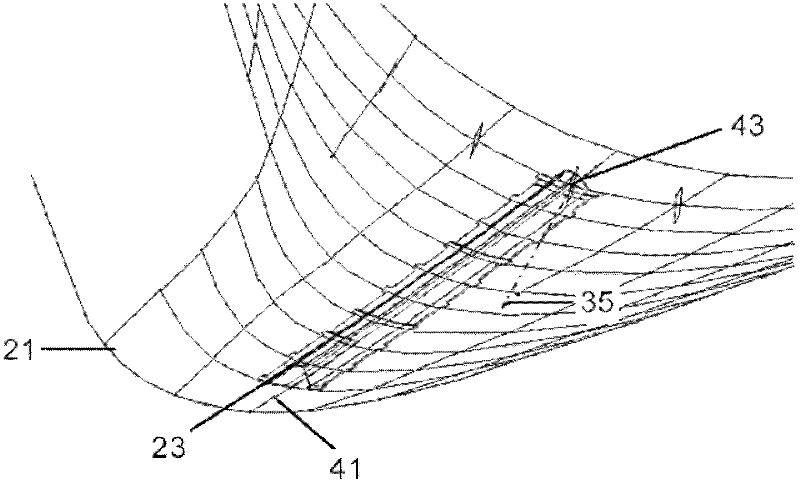

[0017] Part 11 is generally frusto-conical or tubular, formed by an outer skin 21 and a plurality of omega-shaped longitudinal beams 23 within the outer skin. The clamp 13 includes a slot 15 similar in shape to the longitudinal beam 23 .

[0018] The process of manufacturing component 11 by using composite material (such as carbon fiber composite material CFC (Carbon Fiber Composite)) mainly includes: the first step, the Ω-shaped longitudinal rib 23 is arranged in the groove 15 in an "uncured" state; In the second step, the composite material is laminated on the jig to form the skin 21; in the third step, the part 11 is consolidated in a high-pressure vessel;

[0019] In order to demould the part 11 it must first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com